High-temperature-resistant and low-shrinkage polyarylester fiber master batch/polypropylene composite material and preparation method thereof

A polyarylate fiber and composite material technology, which is applied in the field of modified plastics to achieve the effects of good flow properties, uniform dispersion and high flexural modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

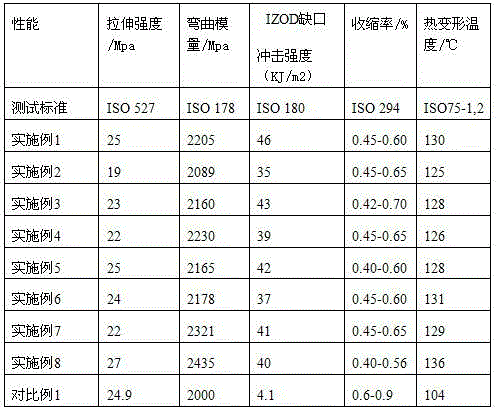

Examples

Embodiment 1

[0041] 50 parts of polypropylene, 20 parts of mineral filler talcum powder, 2 parts of compatibilizer polypropylene grafted maleic anhydride, 10 parts of toughening agent POE, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168 Add 0.3 parts and 0.6 parts of lubricant calcium stearate into the high-speed mixer and mix at high speed for 2 minutes, then put the uniformly mixed mixture into the main feeding hopper of the extruder; Add 20 parts of pellets into the hopper out of the feeding port on the side of the extruder for mixing, melting, extrusion and granulation to obtain a high temperature resistant, low shrinkage polyarylate fiber masterbatch / polypropylene composite material. The temperature of each zone of the barrel of the extruder is 195-230°C, the screw speed is 450r / min, the melt pressure is 1.5MPa, and the vacuum degree is -0.06MPa.

[0042]

Embodiment 2

[0044] 40 parts of polypropylene, 10 parts of mineral filler talcum powder and 10 parts of wollastonite, 3 parts of compatibilizer POE-g, 15 parts of toughening agent POE, 0.2 parts of antioxidant 1010, 10 parts of wollastonite Add 0.1 part of oxygen agent 168 and 1 part of lubricant N,N'-ethylenebisstearamide into the high-speed mixer and mix at high speed for 3 minutes, then put the evenly mixed mixture into the main feeding hopper of the extruder Middle; Add 25 parts of polyarylate fiber masterbatches weighed into the hopper out of the feed port on the side of the extruder for mixing, melting, extruding and granulating to obtain high temperature resistant, low shrinkage polyarylate fiber masterbatch / poly Acrylic composite. The temperature of each zone of the barrel of the extruder is 195-230°C, the screw speed is 500r / min, the melt pressure is 1.8MPa, and the vacuum degree is -0.1MPa.

[0045]

Embodiment 3

[0047] 60 parts of polypropylene, 15 parts of mineral filler talcum powder, 3 parts of compatibilizer POE-g, 8 parts of toughening agent POE, 0.2 part of antioxidant 1010, 0.3 part of antioxidant 168, Add 0.1 part of anti-DSTDP and 0.5 part of lubricant calcium stearate into the high-speed mixer and mix at high speed for 3 minutes, then put the uniformly mixed mixture into the main feeding hopper of the extruder; put the weighed polyarylate Add 20 parts of the fiber masterbatch into the hopper out of the feeding port on the side of the extruder for mixing, melting, extrusion and granulation to obtain a high temperature resistant, low shrinkage polyarylate fiber masterbatch / polypropylene composite material. The temperature of each zone of the barrel of the extruder is 195-230°C, the screw speed is 460r / min, the melt pressure is 1.5MPa, and the vacuum degree is -0.04MPa.

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com