Invisible riser for ingot casting and heat-preservation method thereof

A technology for die-casting ingots and caps, which is applied to the field of invisible caps for die-casting ingots, can solve the problems of poor ingot shrinkage, low yield and high consumption, so as to reduce the consumption of thermal insulation materials and labor, and improve the ingot casting. Quality, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

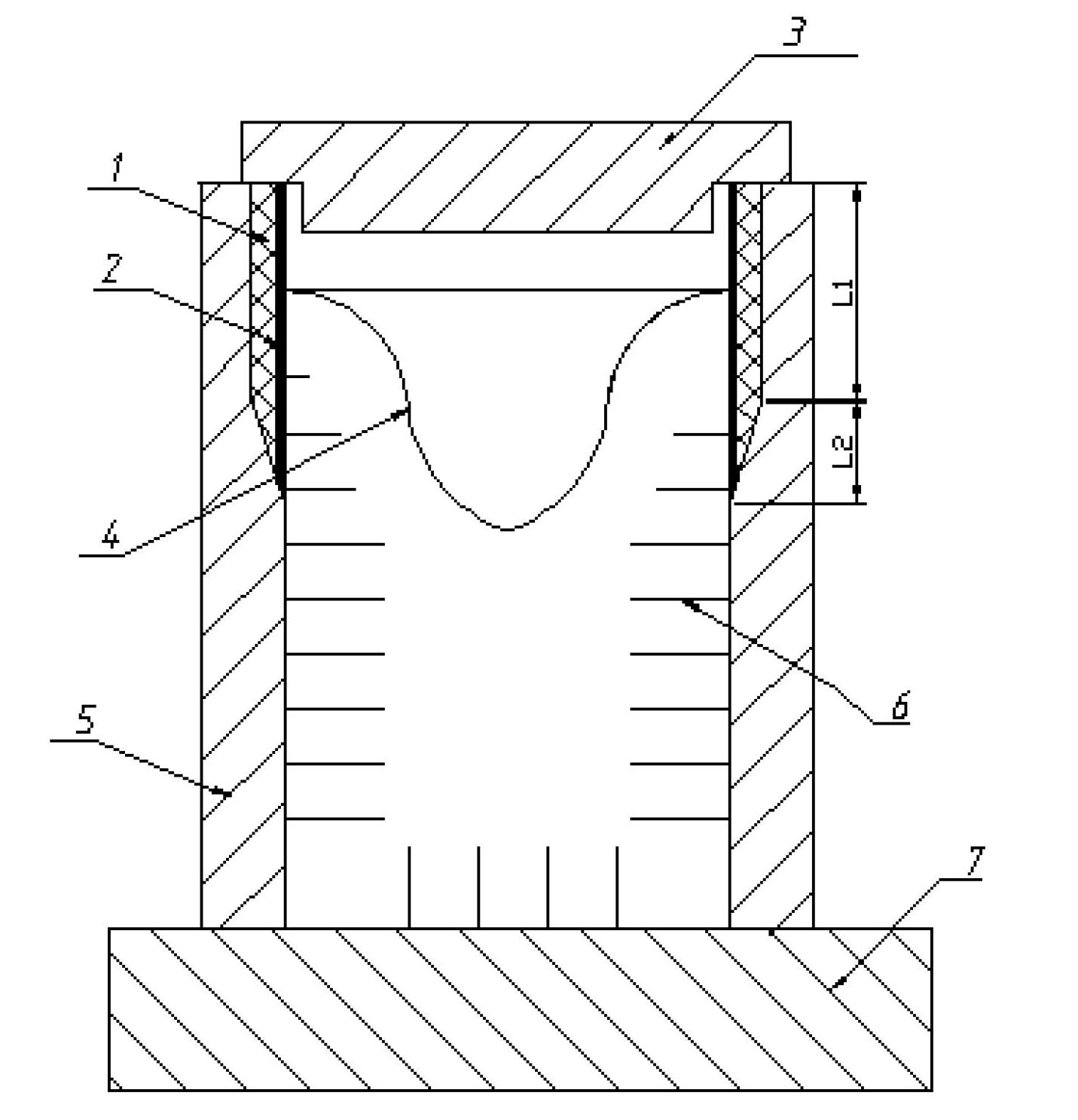

[0034] A die-cast ingot cap mouth, including a heat insulating layer 1 and a protective layer 2, the heat insulating layer 1 is directly painted or sprayed on the inner wall of the cast film to a thickness of 12mm, and the outer surface of the heat insulating layer 1 is painted with the protective layer 2 . The heat insulation layer plays the role of heat preservation and high temperature resistance, and the protective layer plays the role of high temperature resistance, non-stick and erosion resistance. The thickness of the heat insulation layer 1 is 16 mm; the thickness of the protective layer 2 is 0.1 mm.

[0035] The heat insulation layer and the protective layer are adhered to the inner wall of the casting film and maintain the original geometric shape of the inner cavity of the casting film, so as to realize the substantial non-cap casting.

[0036] The heat insulation layer is divided into an equal thickness section L1 and a transition section L2. The equal thickness s...

Embodiment 2

[0042] Others are the same as embodiment 1, the difference is:

[0043] A die-cast ingot cap opening, including a thermal insulation layer 1 and a protective layer 2, the thermal insulation layer 1 is directly painted or sprayed on the inner wall of the cast film to a thickness of 20mm, and the outer surface of the thermal insulation layer 1 is coated with the protective layer 2 . The heat insulation layer plays the role of heat preservation and high temperature resistance, and the protective layer plays the role of high temperature resistance, non-stick and erosion resistance. The thickness of the heat insulating layer 1 is 12mm; the thickness of the protective layer 2 is 0.15mm.

[0044] The heat insulation layer and the protective layer are adhered to the inner wall of the casting film and maintain the original geometric shape of the inner cavity of the casting film, so as to realize the substantial non-cap casting.

[0045] The heat insulation layer is divided into an eq...

Embodiment 3

[0048] Others are the same as embodiment 2, the difference is:

[0049] A mold ingot casting mold with a temperature gradient, comprising the die casting ingot hat mouth of the present invention, an ingot 5 and a chassis 7, the ingot 5 and the chassis 7 form a mold cavity, and the mold casting ingot hat mouth is located at the top of the ingot 5 within the reserved space.

[0050]Die-cast ingot cap mouth, including heat insulation layer 1 and protective layer 2, heat insulation layer 1 is directly painted or sprayed on the inner wall of cast film, brushed to a thickness of 20mm, and the outer surface of heat insulation layer 1 is painted with protective layer 2; The thickness of the thermal insulation layer 1 is 12mm; the thickness of the protective layer 2 is 0.15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com