Preparation method and application of intelligent controlled-release targeting nanometer oil-displacing agent microcapsule

An intelligent controlled-release and oil-displacing agent technology, applied in the direction of microsphere preparation, chemical instruments and methods, microcapsule preparations, etc., can solve the problems of salt and high temperature resistance, strong heterogeneity of oil layers, loss, etc., to achieve Reduce the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

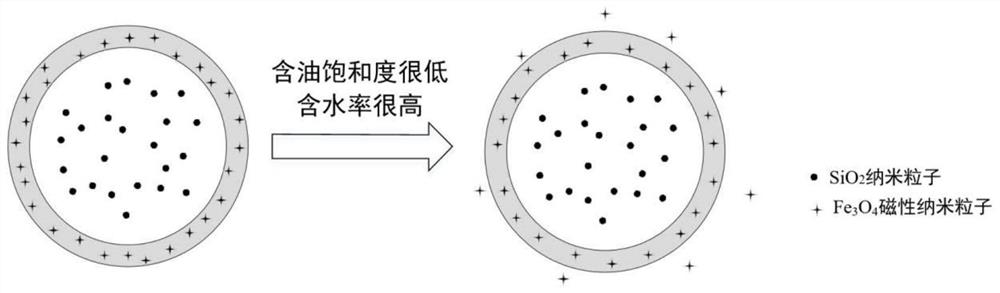

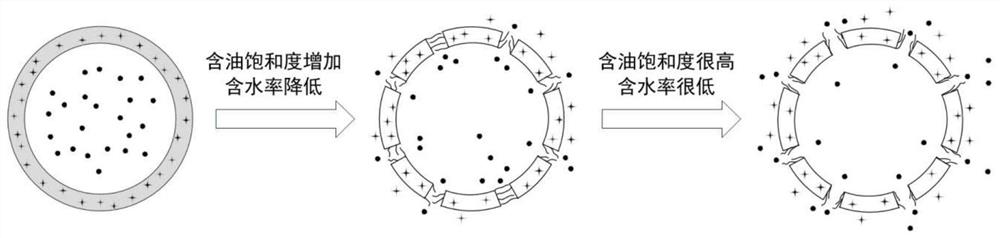

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Core material treatment: use silica spherical particles uniformly dispersed between 15nm and 30nm in particle size as a template, and use solid paraffin fixation method to embed nano-silica particles into the emulsion interface of solid paraffin / water two phases , and then use 5 parts of coupling agent to modify the surface of nano-silica particles to prepare modified nano-silica particles, rinse and dry.

[0032] (2) Configure the intermediate water phase: add 30 parts of acrylamide (AM) monomer and 5 parts of environment-responsive nanoparticles to 100 parts of distilled water, stir well to dissolve, and obtain the intermediate water phase.

[0033] (3) Preparation of magnetic nanoparticles: the nanomaterial FeSO 4 ·7H 2 O with NaOH, trisodium citrate and NaNO 3 Dissolve in deionized water, stir magnetically at 80°C until dissolved, cool to room temperature, separate, wash, and dry to obtain nanometer-scale ferric oxide.

[0034] (4) Configure the oil phase: ad...

Embodiment 2

[0038] (1) Core material treatment: use silica spherical particles uniformly dispersed between 15nm and 30nm in particle size as a template, and use solid paraffin fixation method to embed nano-silica particles into the emulsion interface of solid paraffin / water two phases , and then use 5 parts of coupling agent to modify the surface of nano-silica particles to prepare modified nano-silica particles, rinse and dry.

[0039] (2) Configure the intermediate water phase: add 35 parts of N-isopropylacrylamide (NIPAM) monomer and 5 parts of environment-responsive nanoparticles to 100 parts of distilled water, stir well to dissolve, and obtain the intermediate water phase.

[0040] (3) Preparation of magnetic nanoparticles: the nanomaterial FeSO 4 ·7H 2 O with NaOH, trisodium citrate and NaNO 3 Dissolve in deionized water, stir magnetically at 80°C until dissolved, cool to room temperature, separate, wash, and dry to obtain nanometer-scale ferric oxide.

[0041] (4) Configure the...

Embodiment 3

[0045] (1) Core material treatment: use silica spherical particles uniformly dispersed between 15nm and 30nm in particle size as a template, and use solid paraffin fixation method to embed nano-silica particles into the emulsion interface of solid paraffin / water two phases , and then use 5 parts of coupling agent to modify the surface of nano-silica particles to prepare modified nano-silica particles, rinse and dry.

[0046] (2) Configure the intermediate water phase: add 40 parts of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) monomer and 5 parts of environment-responsive nanoparticles to 100 parts of distilled water, stir well to dissolve them, and obtain the intermediate water box.

[0047] (3) Preparation of magnetic nanoparticles: the nanomaterial FeSO 4 ·7H 2 O with NaOH, trisodium citrate and NaNO 3 Dissolve in deionized water, stir magnetically at 80°C until dissolved, cool to room temperature, separate, wash, and dry to obtain nanometer-scale ferric oxide.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com