Covered stent and manufacturing method thereof

A covered stent and manufacturing method technology, applied in the direction of stents, blood vessels, prostheses, etc., can solve the problem of large shape of covered stents, achieve the effects of reducing stocking costs, increasing blood flow reserves, and stimulating aneurysm shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

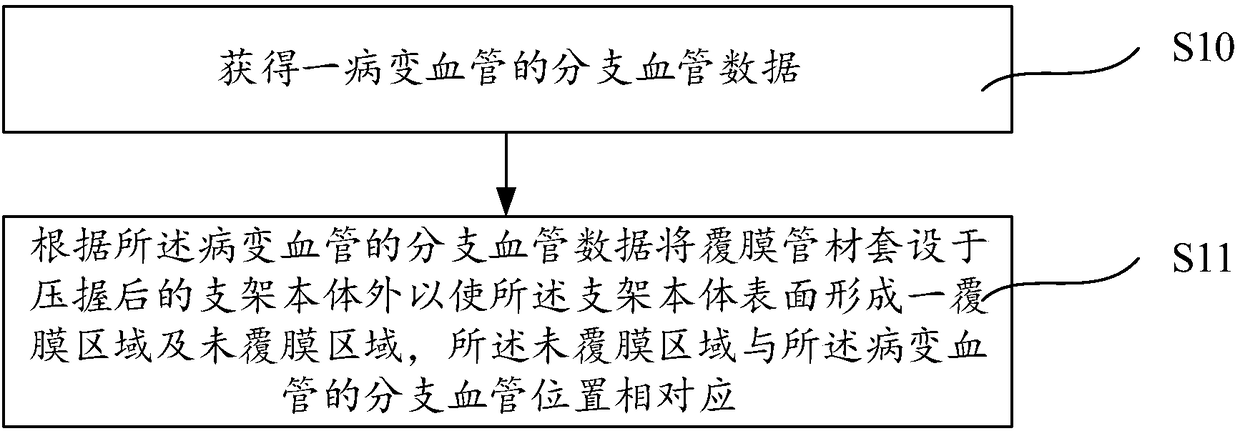

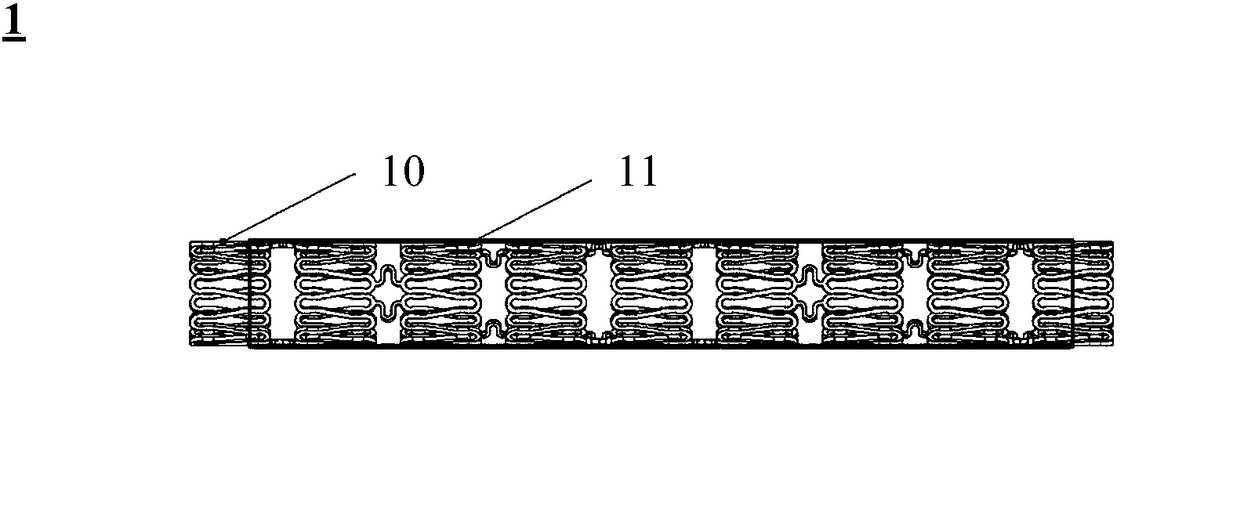

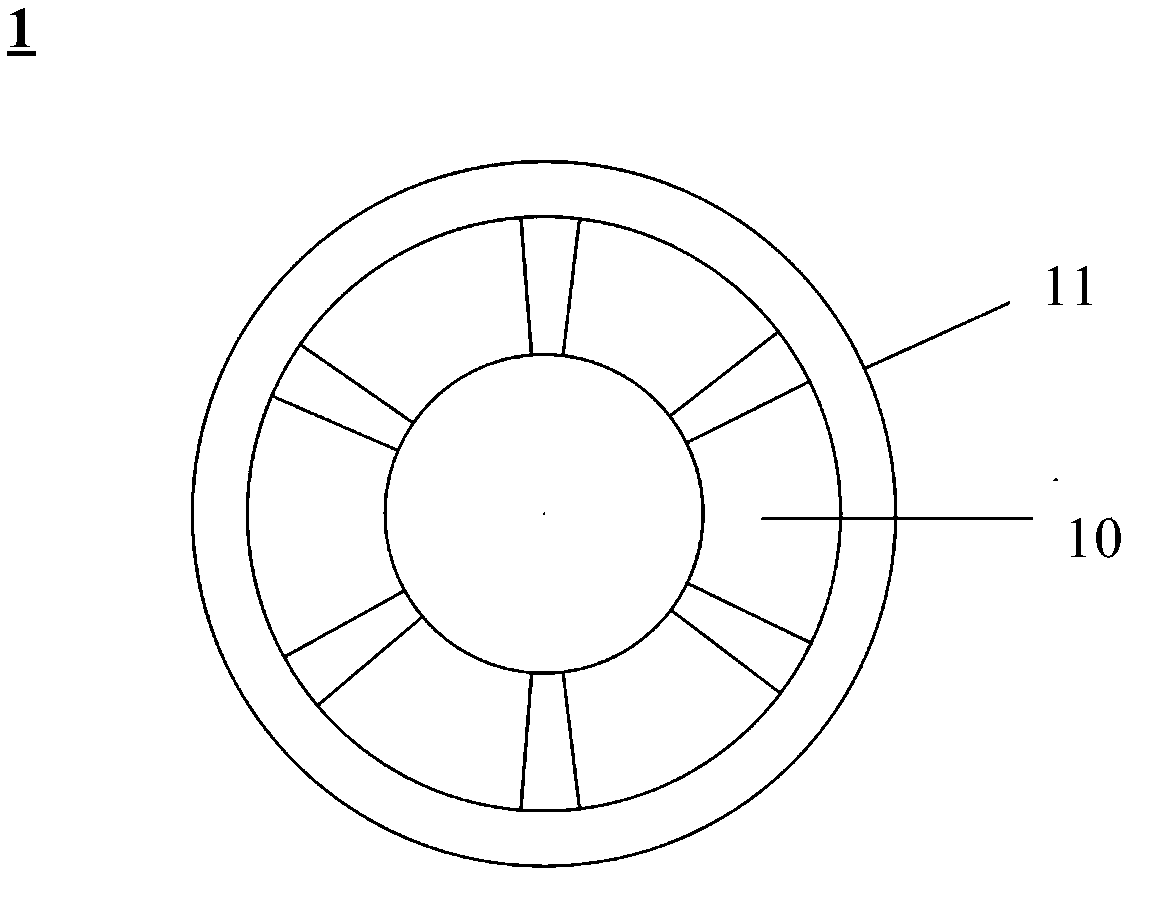

[0045] Please refer to figure 1 , which is a schematic flowchart of the manufacturing method of the stent graft according to the first embodiment of the present invention. like figure 1 As shown, in the first embodiment, the manufacturing method of the stent graft specifically includes:

[0046] First, step S10 is executed: obtaining branch vessel data of a diseased vessel. Here, it mainly includes the position of the branch blood vessel relative to the diseased blood vessel, and further includes data such as the inner diameter of the diseased blood vessel, the inner diameter of the branch blood vessel, and the like. Through the above data, the prepared stent graft can be better adapted to the condition of the patient.

[0047] Next, step S11 is performed: according to the branch vessel data of the diseased blood vessel, the coated tubing is sleeved outside the crimped stent body to form a coated area and an uncoated area on the surface of the stent body, and the uncoated a...

Embodiment 2

[0063] Please refer to Figure 7 , which is a schematic flowchart of the manufacturing method of the stent graft according to the second embodiment of the present invention. like Figure 7 As shown, in the second embodiment, the manufacturing method of the stent graft specifically includes:

[0064] First, step S20 is executed: obtaining branch vessel data of a diseased vessel. Here, it mainly includes the position of the branch blood vessel relative to the diseased blood vessel, and further includes data such as the inner diameter of the diseased blood vessel, the inner diameter of the branch blood vessel, and the like. Through the above data, the prepared stent graft can be better adapted to the condition of the patient.

[0065] Next, step S21 is performed: according to the branch blood vessel data of the diseased blood vessel, the coating solution is coated on the outside of the crimped stent body to form a coated area and an uncoated area on the surface of the stent bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com