Patents

Literature

34results about How to "Change the amount added" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

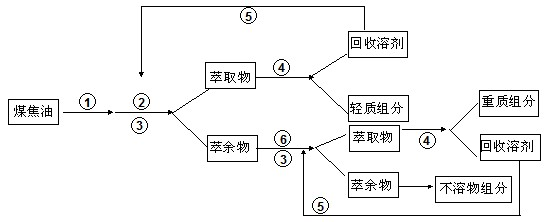

Extracting and separating method of high-temperature coal tar

InactiveCN102492451AHigh purityEfficient separationTar working-up by solvent extractionTime rangeDistillation

An extracting and separating method of high-temperature coal tar belongs to a coal tar separation method. The extracting and separating method includes the step of adding No.1 or No.2 solvent into the coal tar at the ordinary pressure for secondary extraction and separation. Extraction processes are carried out under the pretreatment condition of sufficiently mixing and heating, heating temperature is lower than 150 DEG C, raw materials of the coal tar are respectively mixed with the No.1 or No.2 solvent according to the volume proportion of 1:2 to 4, extraction time ranges from 1 to four hours, extracts and raffinate are obtained after the No.1 solvent and the coal tar are filtered and separated when the system is balanced, and the No.1 solvent is recovered by distillation and recycled. The extracting and separating method has the advantages that energy saving effect of equipment is evident, process is simple and convenient, operation conditions are moderate, manufacturing cost and investment of the equipment are low and benefits are evident. Adding quantity of the solvent and extraction operation parameters are changed, separation depth and process capacity of the coal tar can be flexibly mastered and selectively controlled.

Owner:CHINA UNIV OF MINING & TECH

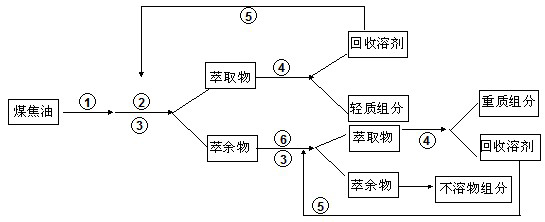

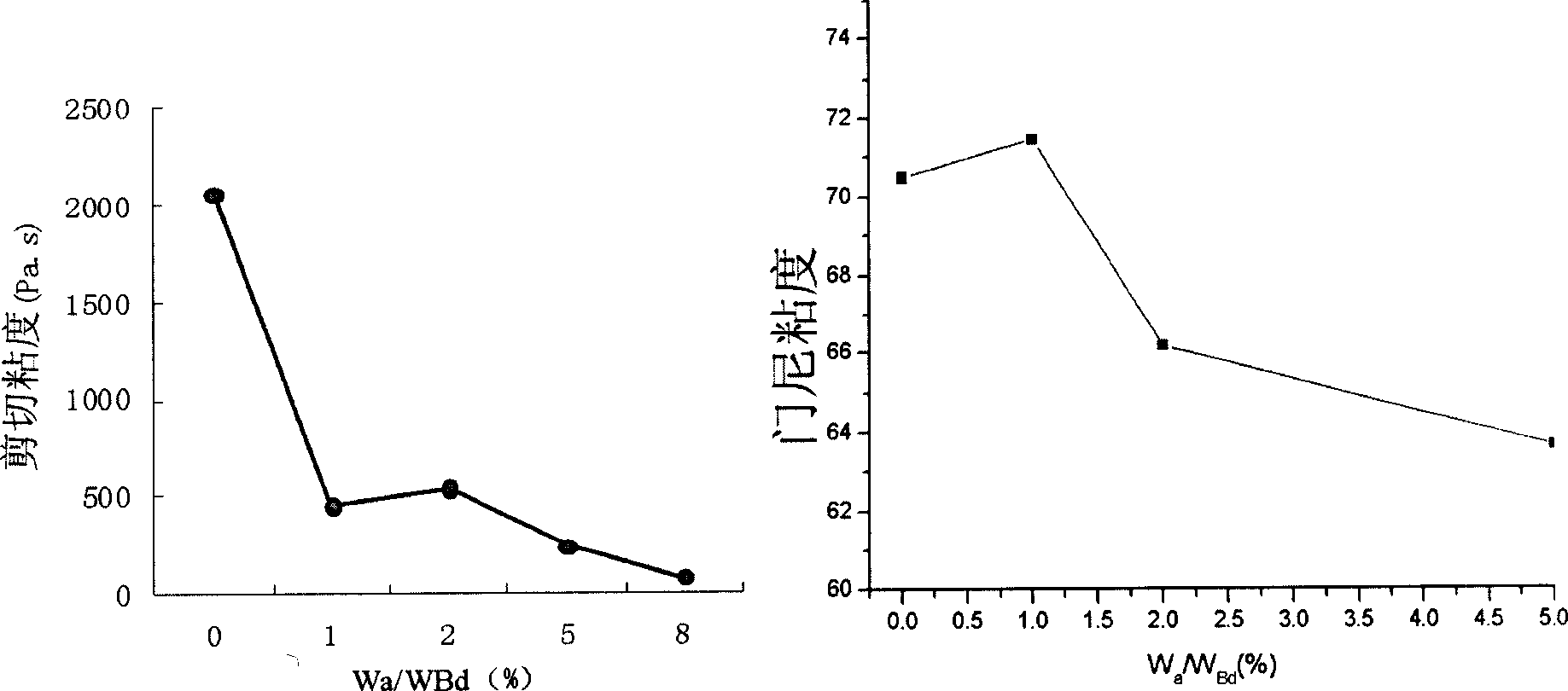

Method for preparing branched high vinyl polybutadiene rubber using molybdenum series catalysis

The invention relates to a method for preparing branched high ethenyl butadiene rubber with molybdenum catalyst, recombining macromolecular monomer prepared through polymerization of molybdenum catalyst butadiene atom free radical or butadiene anion initiated by organic lithium, naphthalene sodium, with coordinate polymerization of butadiene or original position polymerization, to prepare said product with controllable construction. The method is characterized by simple process, special construction of polymer, proper molecular weight and molecular distribution, more than 80% of ethenyl content, controllable property, length, distribution and degree of branching of branch chain in a certain range, good processing behavior and physical mechanics property and low production cost.

Owner:QINGDAO UNIV OF SCI & TECH

Monomer casting nylon composite

The invention discloses a monomer casting nylon composite which is prepared through the catalytic polymerization of caprolactam doped with graphene, wherein the weight ratio of caprolactam to graphene is 100:(0.005-0.095). The invention has the following beneficial effect: the dosage of graphene in caprolactam is changed, thus the mechanical properties and friction performances of the polymerizedmonomer casting nylon can be increased, particularly the impact resistance and wear resistance can be greatly increased, the impact strength is 2-4 times that of the material prepared by the prior art and the volume erosion rate is 7.7%-26.8% of that of the material prepared by the prior art. Therefore, the composite can be used to prepare workpieces with wider application range.

Owner:HENAN UNIV OF SCI & TECH

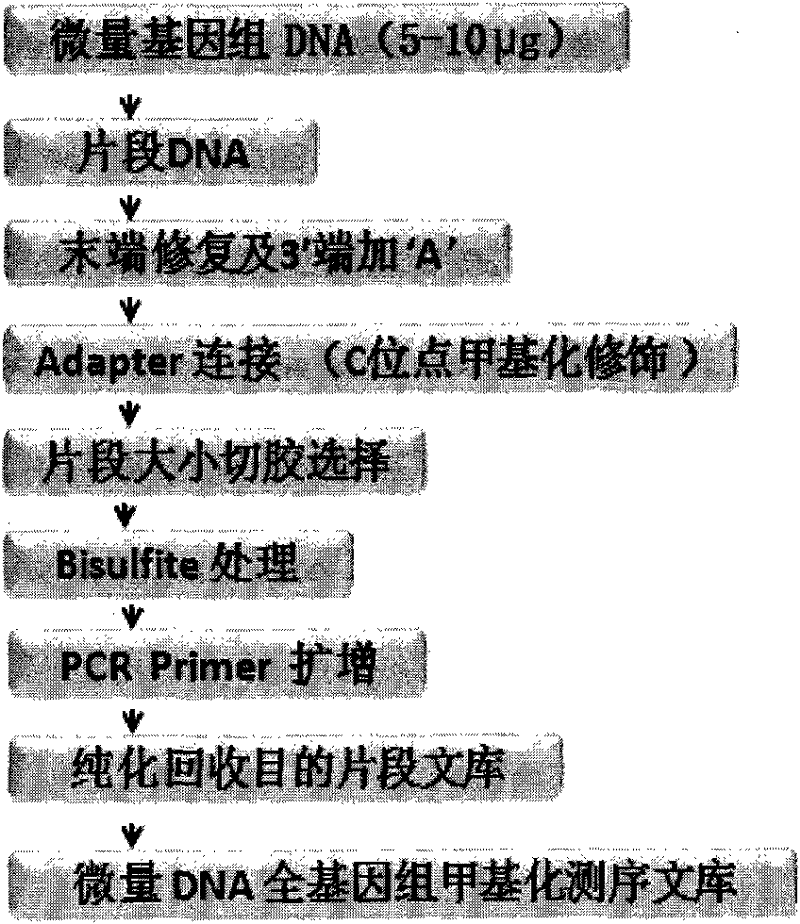

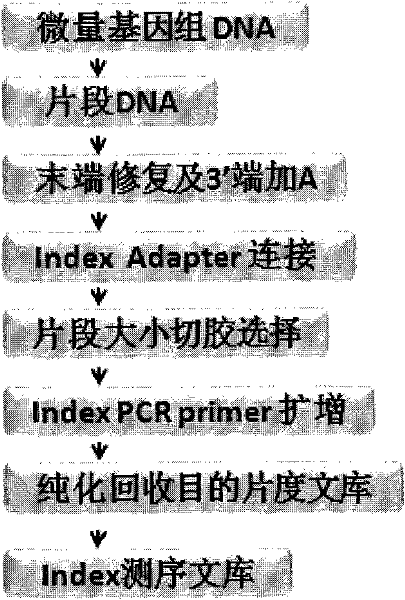

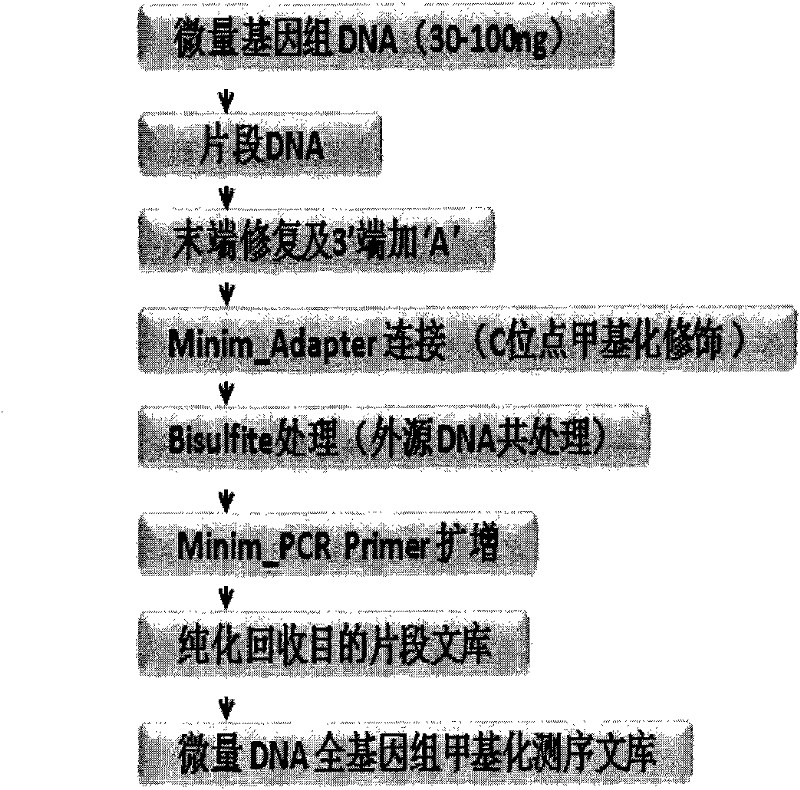

Method for accurate detection of whole genome methylation sites by utilizing trace genome DNA (deoxyribonucleic acid)

ActiveCN102409408AHigh amplification efficiencyImprove efficiencyMicrobiological testing/measurementLibrary creationFragment sizeExogenous DNA

According to the invention, based on Illumina common tag library sequencing and methylation normal sequencing and combining a common library tag sequencing method, a new method for accurate detection of whole genome methylation sites by utilizing trace genome DNA (deoxyribonucleic acid) is built. According to the method, in the construction of a methylation library by using trace genome DNA, exogenous DNA is innovatively added to carry out bisulfite high-efficiency co-treatment; and at the same time, fragment size selection is not needed, and PCR (polymerase chain reaction) amplification is directly carried out after bisulfite treatment. By the method, the defects that in the common methylation sequencing, samples can not be mixed, the PCR amplification efficiency is low and the trace DNAsample can not be researched are overcome.

Owner:BGI TECH SOLUTIONS

Method for preparing high purity silicon carbide honeycomb ceramic body using nanometer silicon carbide as sintering adjuvant

InactiveCN1807356ALow expansion thermal shock resistanceLow abrasion and chemical resistanceCeramicwareProportional controlMicrowave

The invention relates to a high-pure SiC honeycomb-shaped ceramic catcher. Wherein, selecting pure SiC and nano SiC as porous ceramic aggregate and sinter auxiliary agent by ratio as 100: 1~15; using methylcellulose and tung oil as conjugation agent and plasticizer to prepare with proper water by ratio as 1: 1~3; obtaining the biscuit with extrusion molding technique with non-solid phase material within 13~31% by adjusting the ratio and quantity; dewatering the biscuit with first the microwave heating then the oven drying; removing the organic material in biscuit with normal heating means; using normal-pressure sinter to change the average size, auxiliary agent content and sintering temperature to realize the connected web distribution of the ceramic material.

Owner:黄黎敏 +1

Powder metallurgy manufacturing method for valve flap of check valve

The invention discloses a powder metallurgy manufacturing method for a valve flap of a check valve. The powder metallurgy manufacturing method comprises the following steps of: a, selecting the following powder raw materials in percentage by weight to form the valve flap through powder metallurgy one-time pressing: balance of iron-base powder, 0.7 percent of carbon, 0.9 percent of molybdenum, 1.1 percent of aluminum, 0.9 percent of magnesium, 0.3 percent of tree ash and 0.8 percent of zinc stearate; and b, placing the valve flap product obtained by sintering and forming into engine oil of No. 20-30 to soak for 2-3 hours, and performing water atomization steam treatment at the temperature of 550-650 DEG C for 3-5 hours. The valve flap is a powder metallurgy material which is mainly made of alloy steel powder and has the characteristics of capabilities of improving the strength, the corrosion resistance and the wear resistance of metal components and reducing the manufacturing cost.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

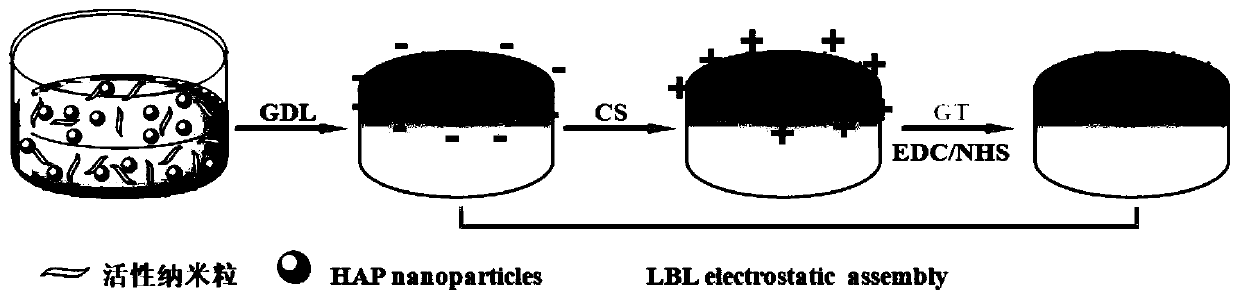

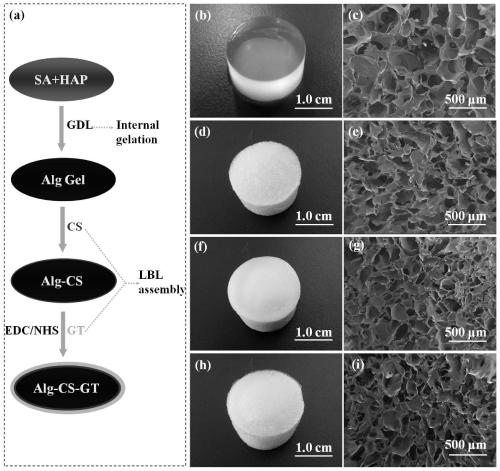

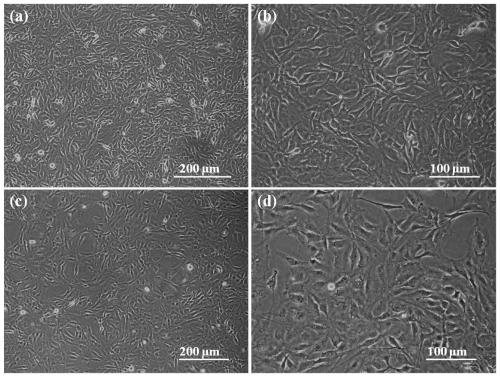

Alginate complex gel stent material constructed based on homogeneous phase crosslinking and layer-by-layer self-assembly technology and preparation method thereof

InactiveCN110302427AGood 3D shapeUniform pore structurePharmaceutical delivery mechanismProsthesisPolymer scienceSILK SERICIN

The invention relates to a gel material, in particular to an alginate complex gel stent material constructed based on homogeneous phase crosslinking and layer-by-layer self-assembly technology and a preparation method thereof, and belongs to the technical field of tissue engineering. Alginate gel is prepared with an HAP / GDL compound as an endogenous crosslinking agent, wherein the mole ratio of HAP to GDL is 1:10, and meanwhile, it is determined that the mole ratio of the Ca element in the HAP to -COOH in sodium alginate (SA) is 0.18-0.36; afterwards, chitosan (CS) with positive electricity and B-type gelatin (GT) (collagen or sericin) with negative electricity are alternately deposited on the surface of the alginate gel through the electrostatic effect; and finally, the GT (collagen or sericin) on the outermost layer is subjected to covalent crosslinking through an EDC / NHS mixture, and therefore an alginate complex gel stent with homogeneous phase crosslinking is prepared.

Owner:HAINAN NORMAL UNIV

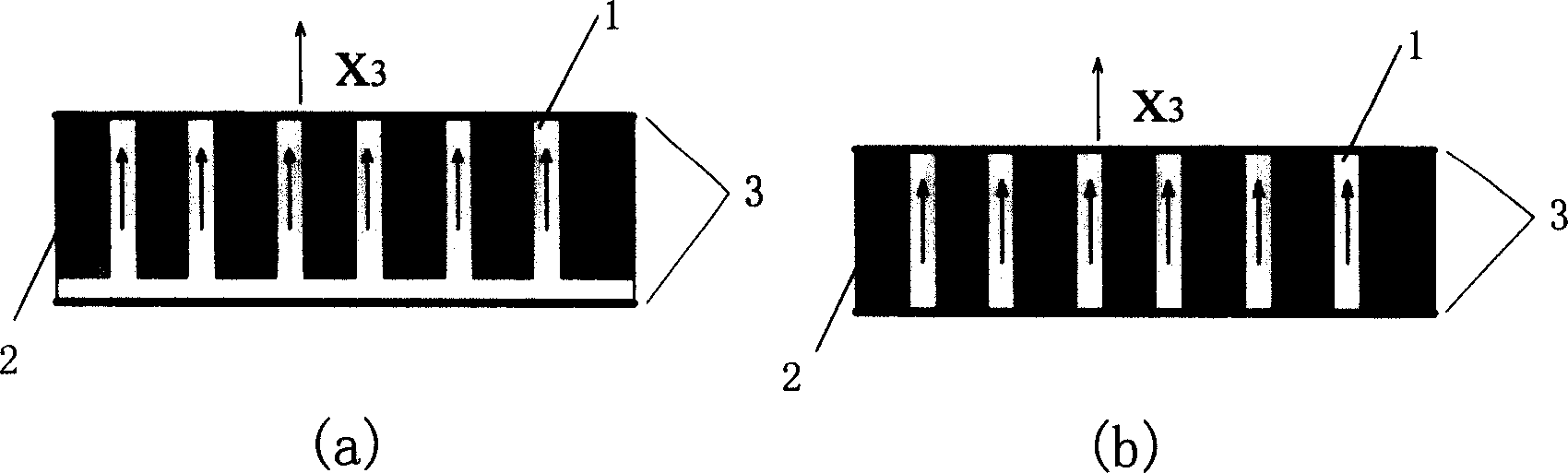

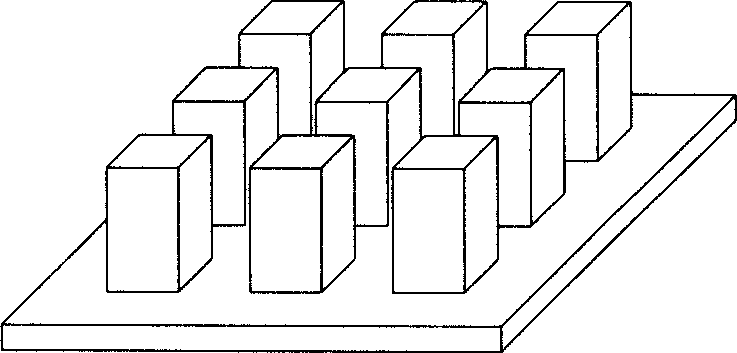

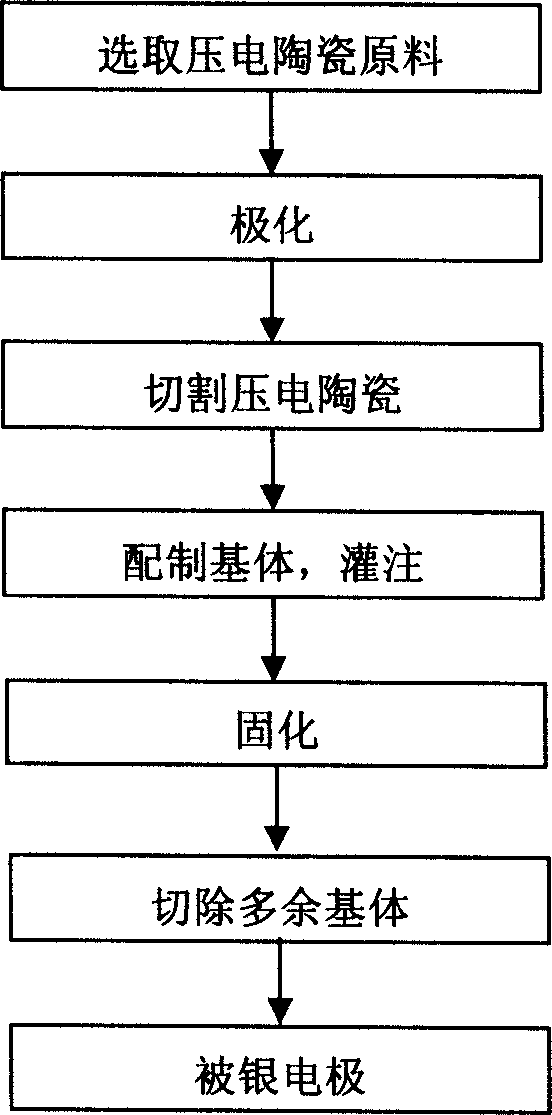

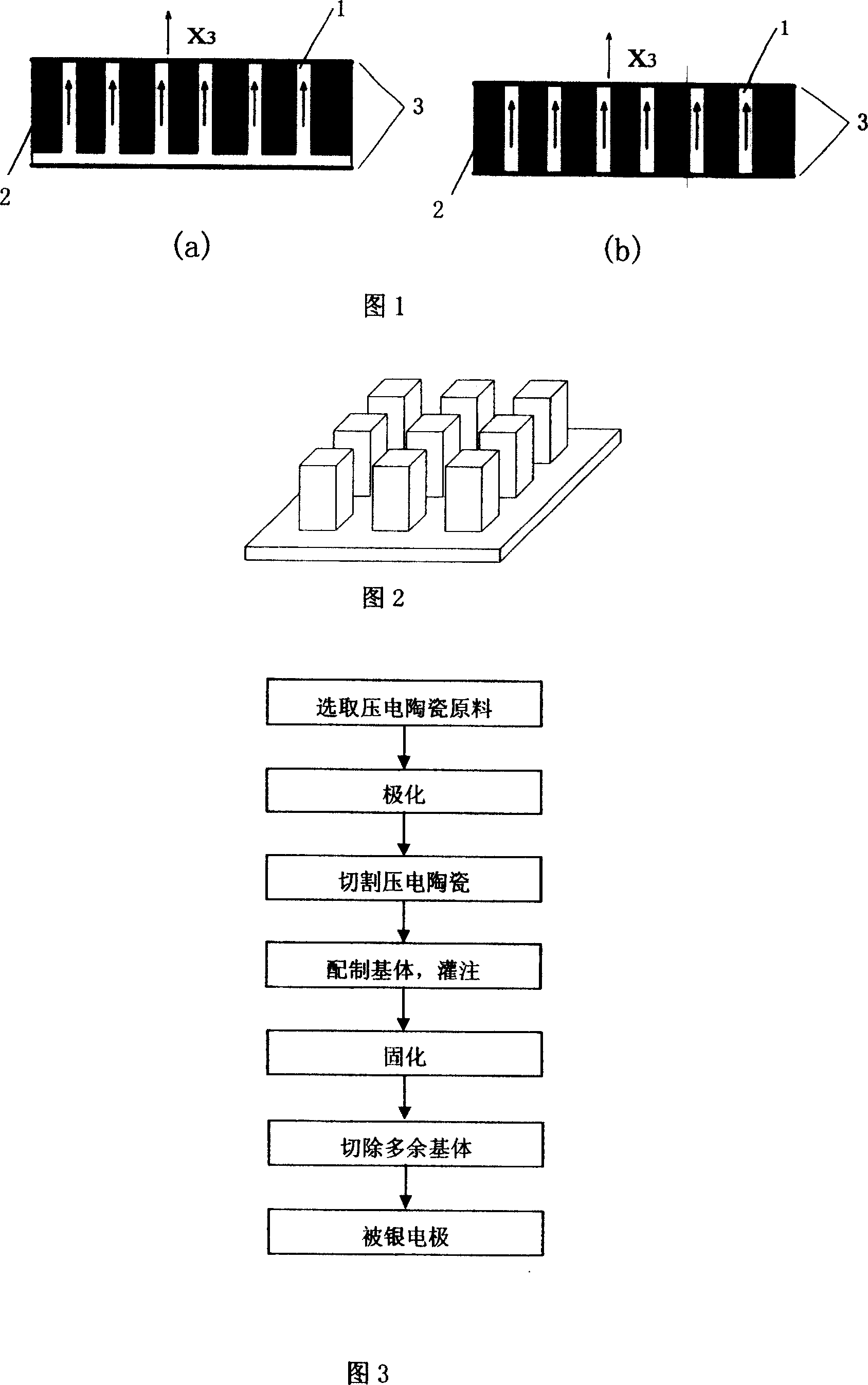

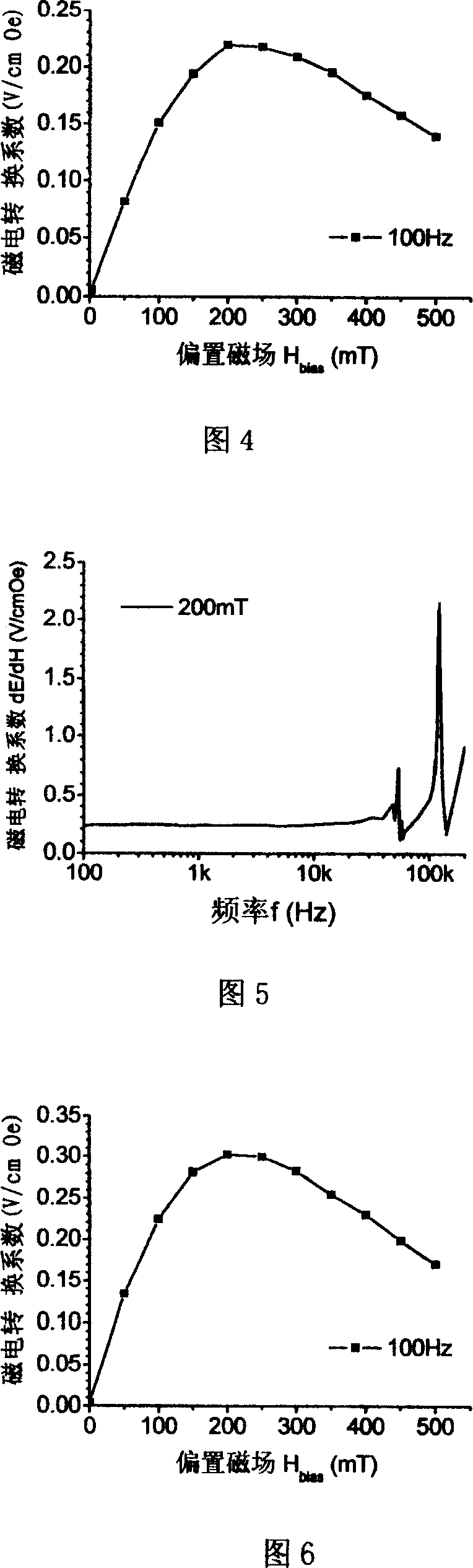

1-3 structure huge magnetoelectric material and preparing process thereof

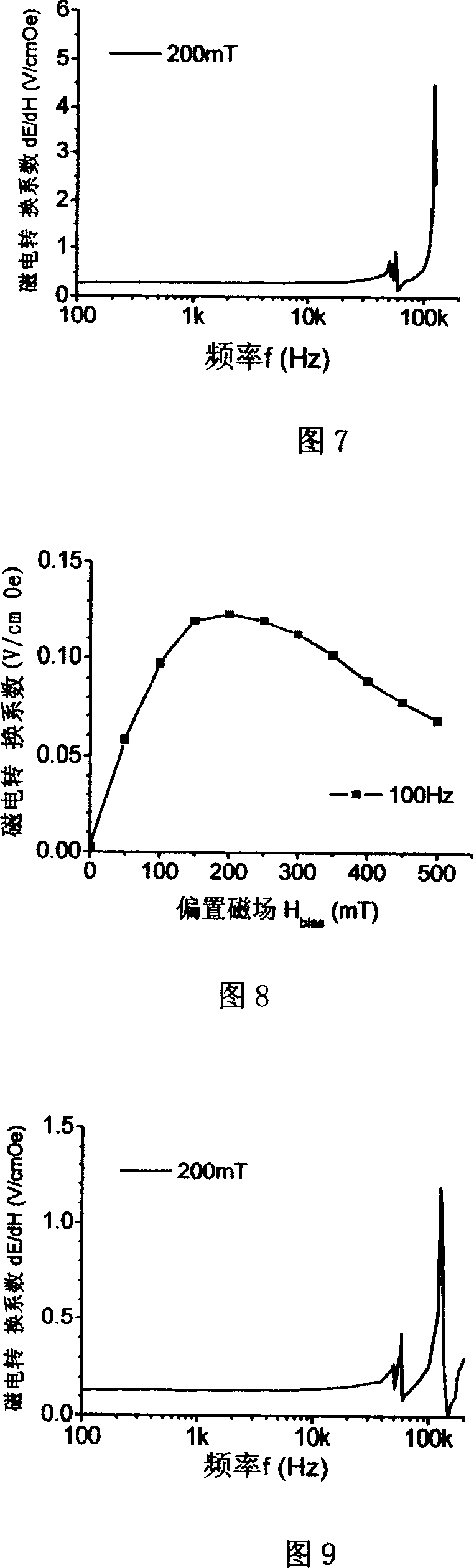

InactiveCN1719635AImprove magnetoelectric propertiesEasy to makeDevice material selectionGalvano-magnetic material selectionElectricityConversion coefficients

This invention relates to a 1-3 structured huge magnet electric material and its preparation method. The material is composed of piezoelectric ceramics, magnetostriction materials and a high-molecular binding agent, among which, one of the dimension of the piezoelectric ceramics is greater than the other two shaped in a long column and distributed in a 3-D matrix composed of the magnetostriction materials powder and the high-molecular binding agent. This 1-3 structured material has high and stable magnetoelectric conversion coefficient, which can be regulated by altering contents of the piezoelectric ceramics.

Owner:TSINGHUA UNIV

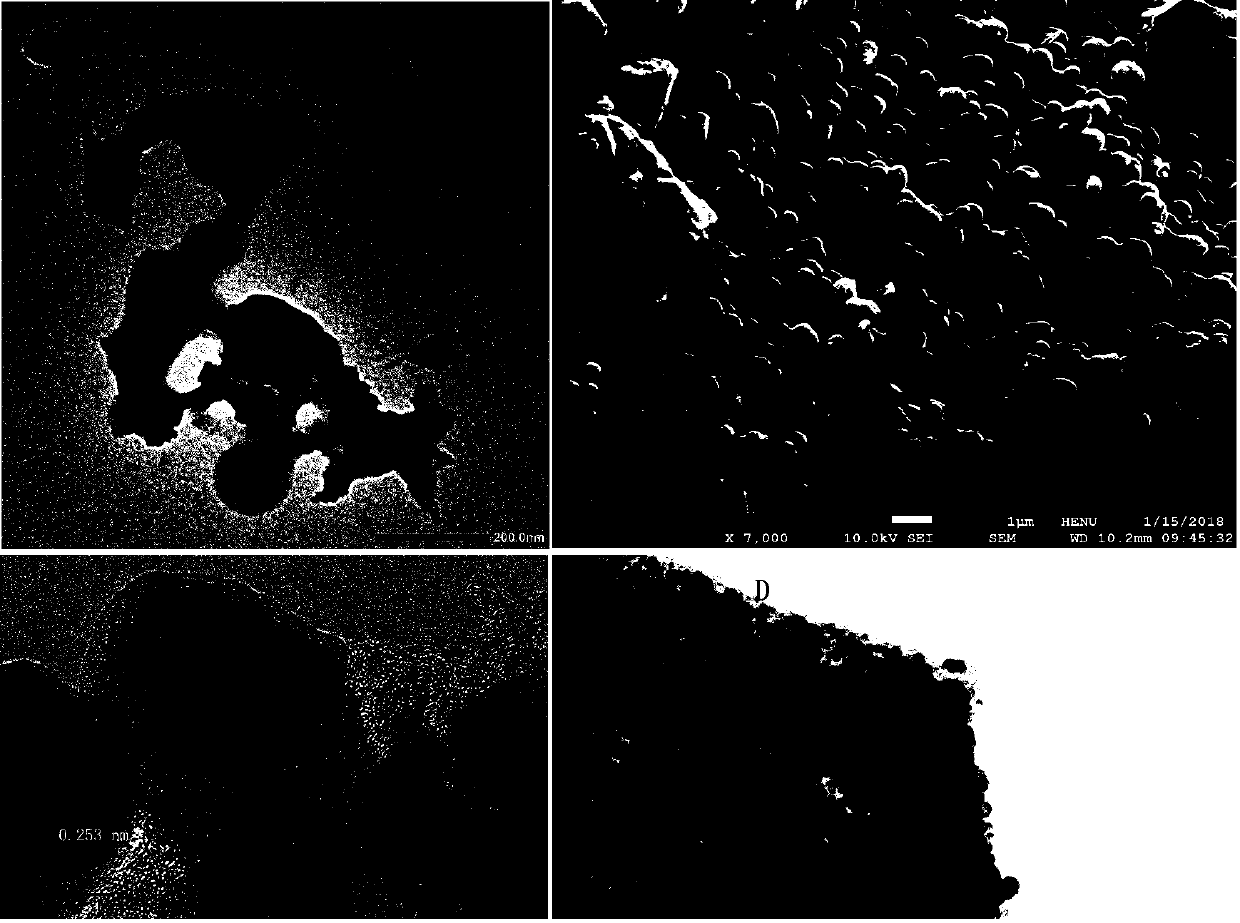

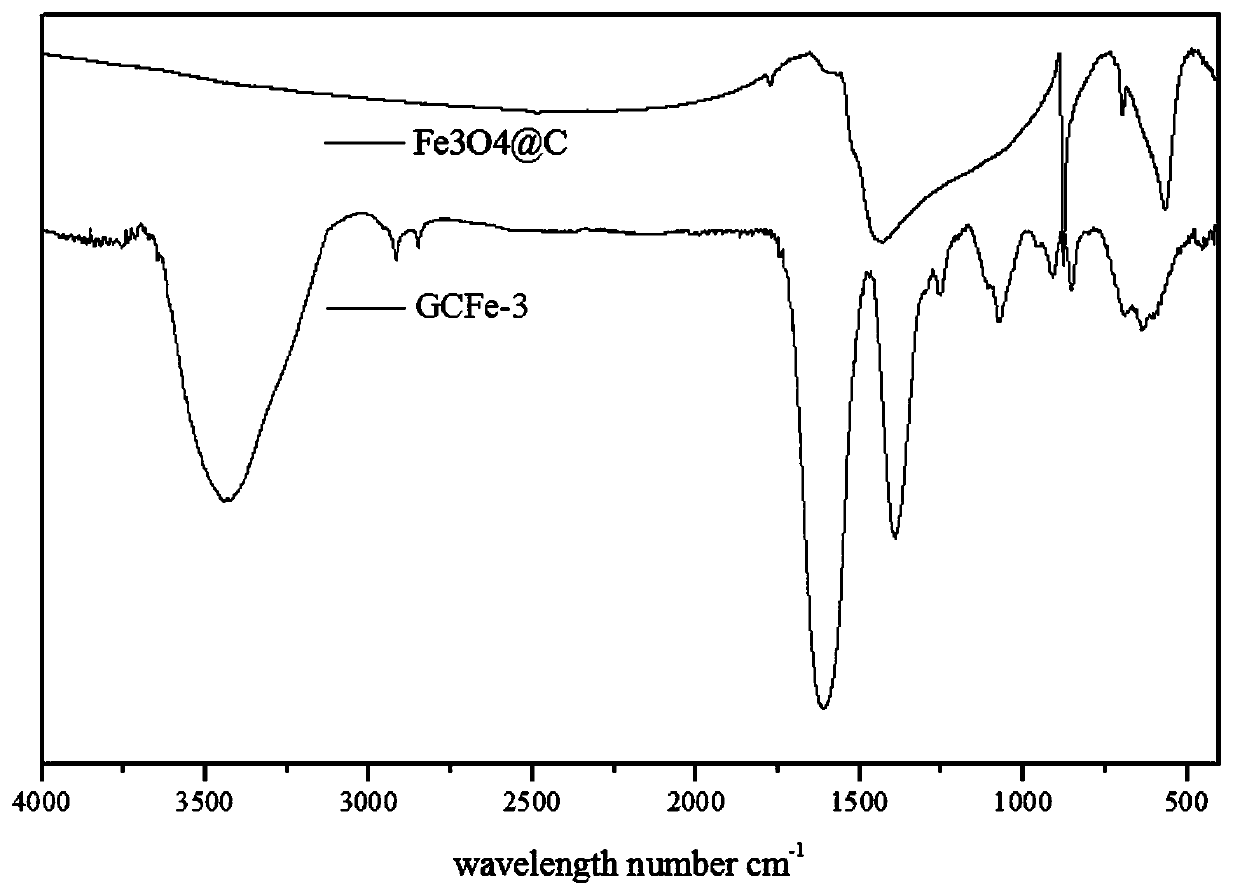

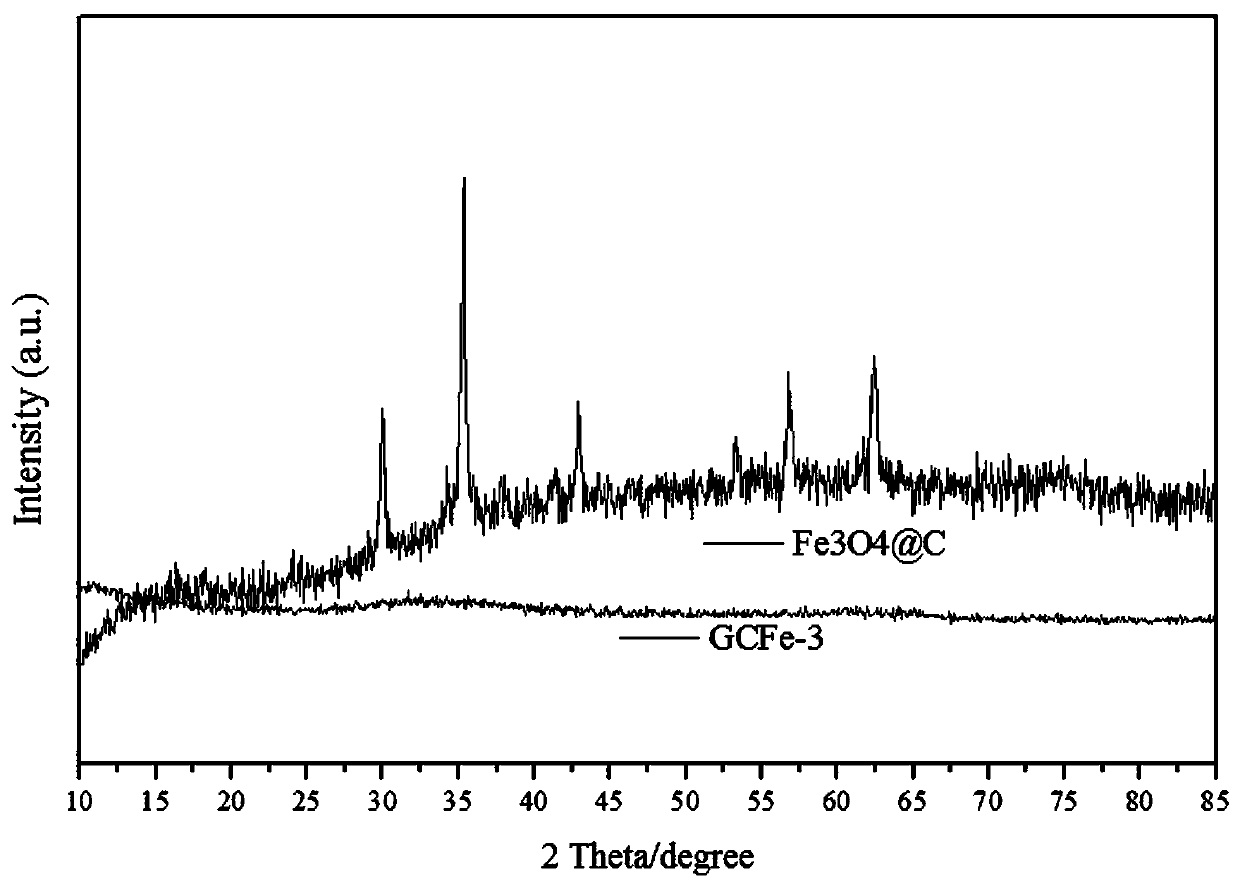

Carbon coated layer thickness adjustable nanometer ferroferric oxide composite material, preparation method and application thereof

InactiveCN110212192APlay a covering roleInhibition of agglomerationMaterial nanotechnologyCell electrodesCarbon layerOxide composite

The invention relates to the field of electrochemical materials, in particular to a carbon coated layer thickness adjustable nanometer ferroferric oxide composite material, a preparation method and application thereof. The preparation method comprises the following steps: firstly, taking sugar, a catalyst and a ferric salt solution as raw materials, reacting for 0.1 to 24 h under the conditions that the pH is 5 to 10 and the temperature is 5 to 90 DEG C, preparing an iron-sugar complex, and thus preparing the carbon coated layer thickness adjustable nanometer ferroferric oxide composite material from the iron-sugar complex through in situ calcinations or a hydrothermal method. The nanometer ferroferric oxide composite material with a carbon coated layer is prepared through different in situ calcinations conditions or the hydrothermal method by using the iron-sugar complex as a precursor, and due to the fact that a multi-stage carbon structure array can play the role of a fixed frame for ferroferric oxide, the volume effect in the charge and discharge cycle process is reduced, and when the composite material serves as the negative electrode of a battery, the performance of the battery can be improved obviously. The thickness of the carbon coated layer inside the carbon coated ferroferric oxide composite material can be changed by changing the additive amounts of sugar and the catalyst.

Owner:HENAN UNIVERSITY

Aerogel-modified polypropylene, ultralight melt-blown non-woven fabric with thermal insulation and heat preservation functions and preparation method of aerogel-modified polypropylene

ActiveCN108677380AChange the amount addedNo sheddingFilament/thread formingMonocomponent polypropylene artificial filamentPorosityPolymer science

The invention discloses aerogel-modified polypropylene, an ultralight melt-blown non-woven fabric with thermal insulation and heat preservation functions and a preparation method of aerogel-modified polypropylene. The preparation method includes the steps that before a polymerization reaction or during the polymerization reaction, an aerogel is added to be mixed with reaction materials with low viscosity, correspondingly uniform dispersion of the aerogel is achieved, and aerogel-modified polypropylene is obtained through preparation, wherein the reaction materials include a propylene monomer,a catalyst and an auxiliary agent, the granularity of the aerogel is within the range from 20 nm to 100 microns, the porosity is within the range from 40% to 99.9%, the stacking density is within therange from 3 g / L to 500 g / L, and the volume of aerogel-modified polypropylene accounts for 20-60% of the total volume of the ultralight melt-blown non-woven fabric which is prepared from aerogel-modified polypropylene and has the thermal insulation and heat preservation functions. Aerogel-modified polypropylene particles with the uniformly dispersed aerogel and great melt-blown performance and theultralight melt-blown polypropylene non-woven fabric with the thermal insulation and heat preservation functions are prepared, and the aerogel in the non-woven fabric does not shed during use.

Owner:江苏弘源淏尔新材料科技有限公司

Peppery taste haw thorn product

InactiveCN1555716AReduce acidityImprove antioxidant capacityConfectionerySweetmeatsPreservativeChili powder

A hot haw food is prepared from fresh haw through removing kernel, washing, softening by steam for 3-8 min, immersing in sugar solution under vacuum for 15-17 hr, dripdrying, proportionally mixing it with chili powder, and baking. Its advantages are proper sour taste, less sugar content, and long storage time.

Owner:徐佩琦

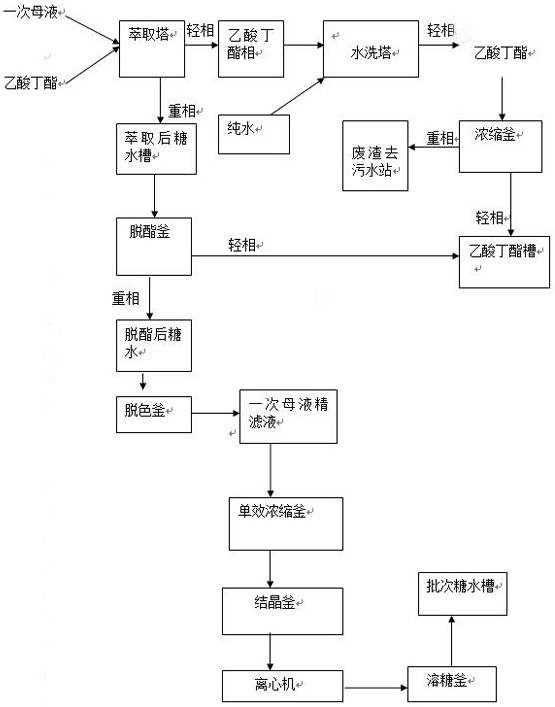

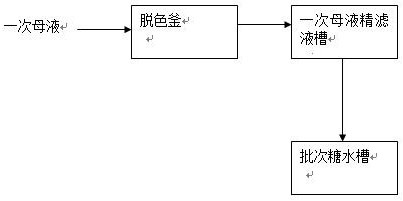

Method for treating sucralose primary mother liquor

InactiveCN112480186AEfficient removalFully removeSugar derivativesSugar derivatives preparationSucroseEthylic acid

The invention relates to a method for treating sucralose primary mother liquor, which is characterized by comprising the following steps: (1) pumping primary mother liquor and butyl acetate into an extraction tower according to a volume ratio of 2-3:1 for countercurrent extraction, and enabling a heavy phase to enter a degreasing kettle; (2) feeding the light phase to enter a water washing tower,adding pure water, feeding butyl acetate after water washing to enter a concentration kettle for concentration, controlling the temperature to be 40-50 DEG C, feeding the light phase to enter a butylacetate tank and the heavy phase to enter a sewage station, and feeding the washed heavy phase to enter a wastewater degreasing kettle; (3) controlling the temperature in the degreasing kettle to be 40-50 DEG C, enabling the light phase to enter a butyl acetate tank, pumping the heavy phase into a decolorizing kettle, and adding activated carbon which accounts for 0.2-0.5% of the mass of the sugarliquid into the decolorizing kettle for decolorization at 45-55 DEG C for 40-80 minutes; and (4) subsequently filtering and primarily concentrating the sugar liquid by controlling the pressure to be0.085-0.095 MPa and the temperature to be 45-55 DEG C, crystallizing the concentrated material until the sugar degree of the mother liquor is 30%, discharging and centrifuging the mother liquid, putting the centrifuged mother liquor into a sugar dissolving kettle, and pumping into a sugar liquid tank in batches. The method has the advantages that the sugar degree is reduced to 25% and the acetic acid content is reduced to 100 PPM from that the sugar degree of the primary mother liquor is 30% and the acetic acid content is 500 PPM.

Owner:ANHUI JINGHE IND

Valve rod powder metallurgy manufacturing method for check valve

ActiveCN103008642AHigh densityChange the amount addedTurbinesOther manufacturing equipments/toolsPowder metallurgyManganese sulfide

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

Submicron yttrium oxide having high specific surface area and preparation method thereof

ActiveCN110655099AChange the amount addedDifferent areaRare earth metal compoundsOXALIC ACID DIHYDRATEActive agent

The invention belongs to the technical field of preparation of rare earth compounds, and in particular, relates to submicron yttrium oxide having high specific surface area and a preparation method thereof. Yttrium oxide with different specific surface areas and particle sizes can be prepared by changing the addition amounts of an organic dispersing agent and an anionic surfactant, oxalic acid isused as a precipitator, and the method has the advantages of large production batch, simple process and accordance with environmental protection requirements. The submicron yttrium oxide having high specific surface area and produced by the method avoids tedious post-treatment avoided, can be prepared by direct sieving, has the advantages of high purity, small ignition vector, low impurity contentand the like, and can meet the requirements of customers on product performance to a greater extent.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

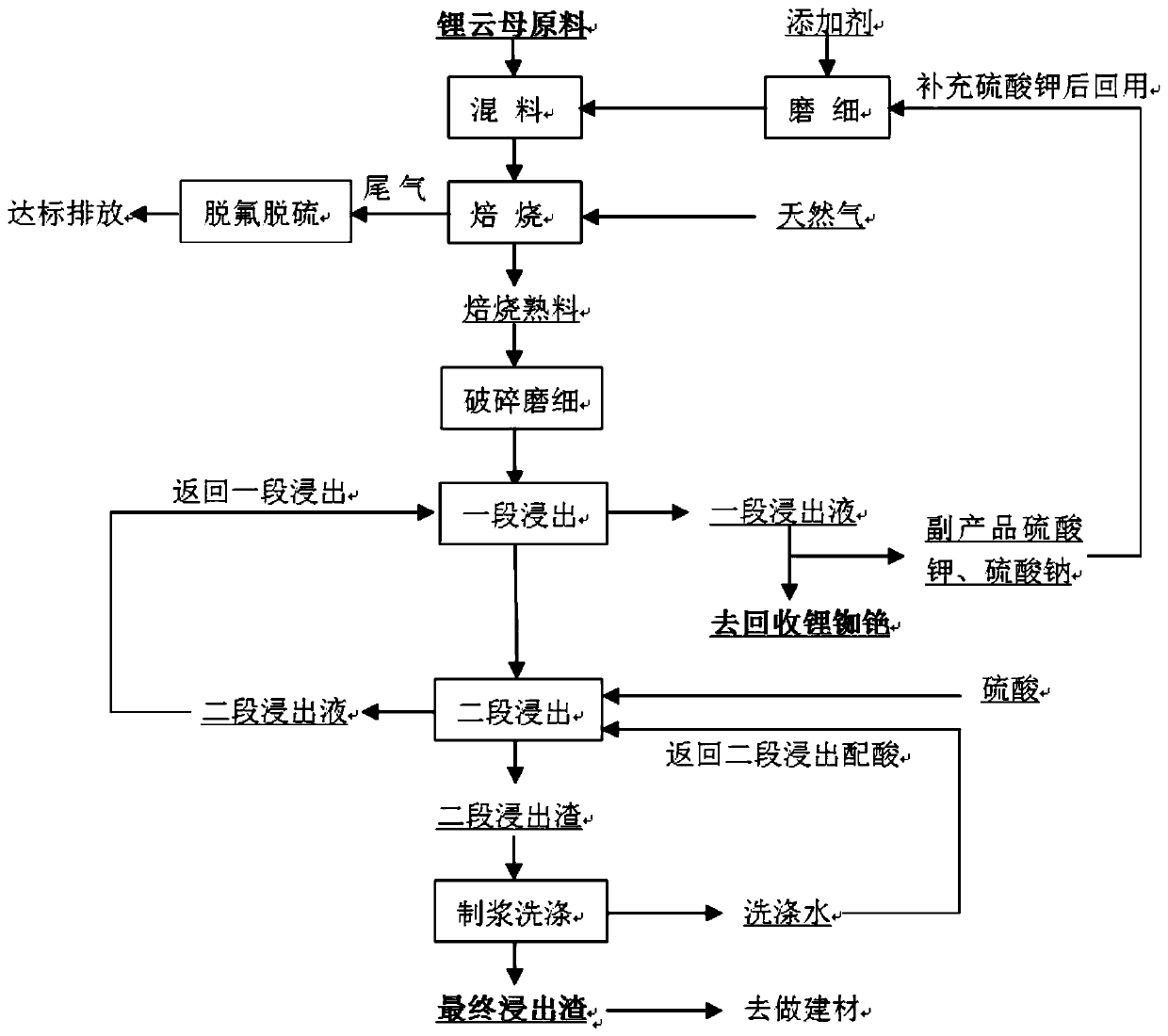

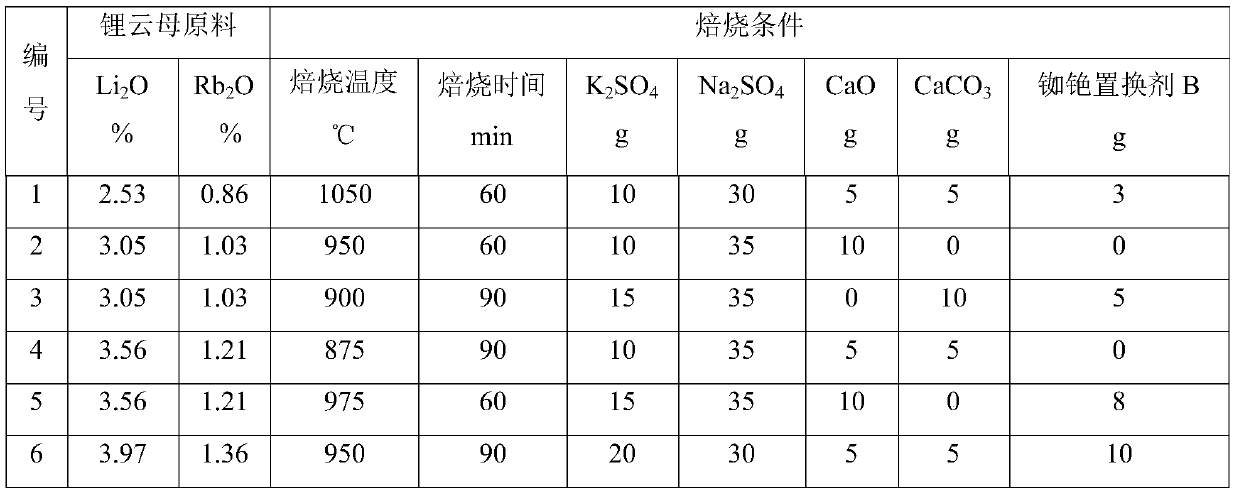

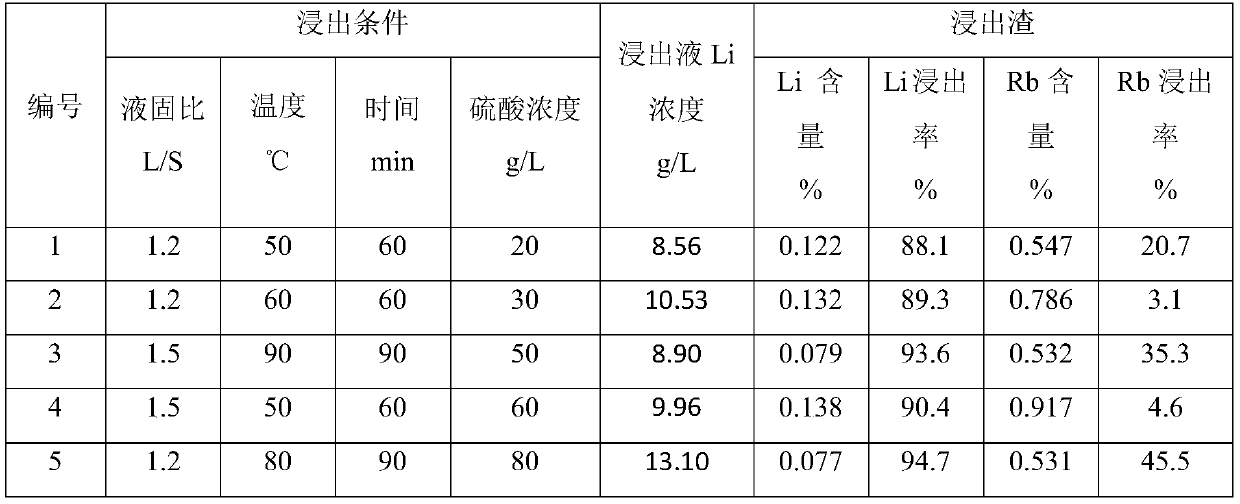

Pretreatment and leaching method of lepidolite

InactiveCN109929993AEasy to handleLess fluorine escapeProcess efficiency improvementLepidoliteMaterials science

The invention relates to the technical field of extracting lithium from ores, and particularly discloses a pretreatment and leaching method of lepidolite. The method comprises the first step of grinding of a reagent, the second step of mixing, the third step of roasting, the fourth step of crushing and grinding, the fifth step of one-stage leaching, the sixth step of two-stage leaching and the seventh step of pulping and washing. The method is economical and high in operability and has the industrial application value, calcium oxide and calcium carbonate are added during roasting to play a role of fixing fluorine, the sintering performance of the calcine can be improved, and calcine is loose and fragile.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

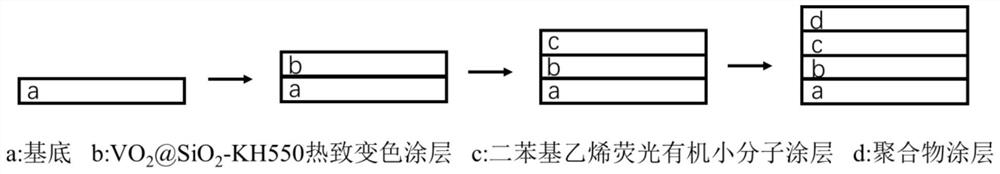

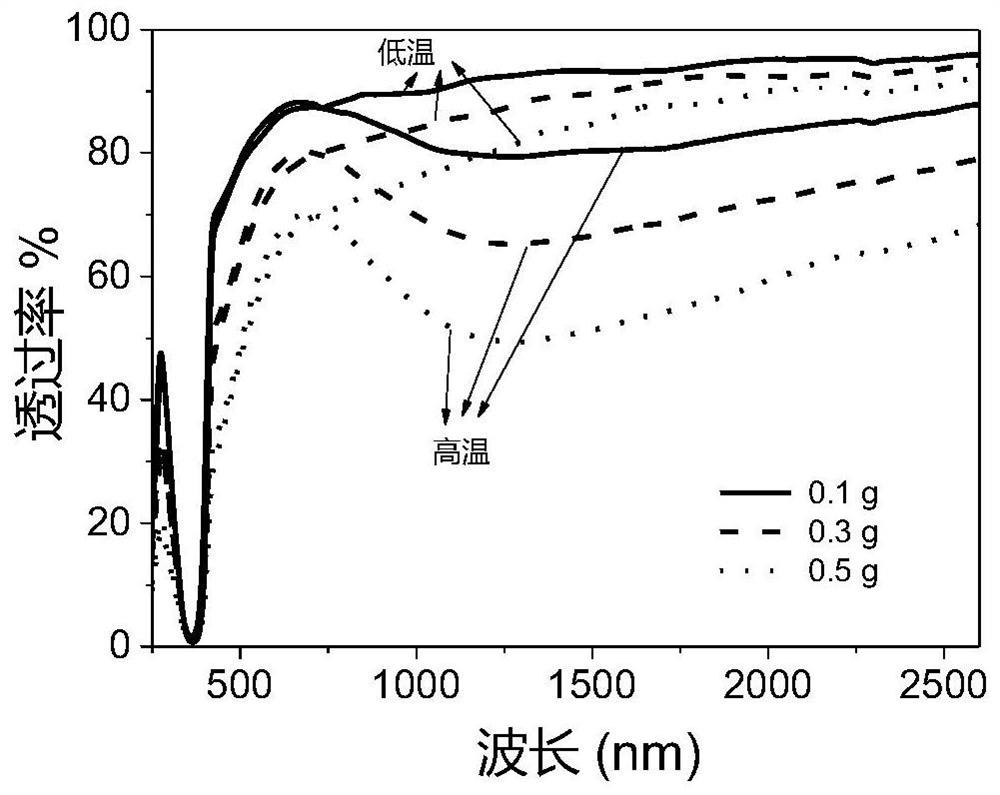

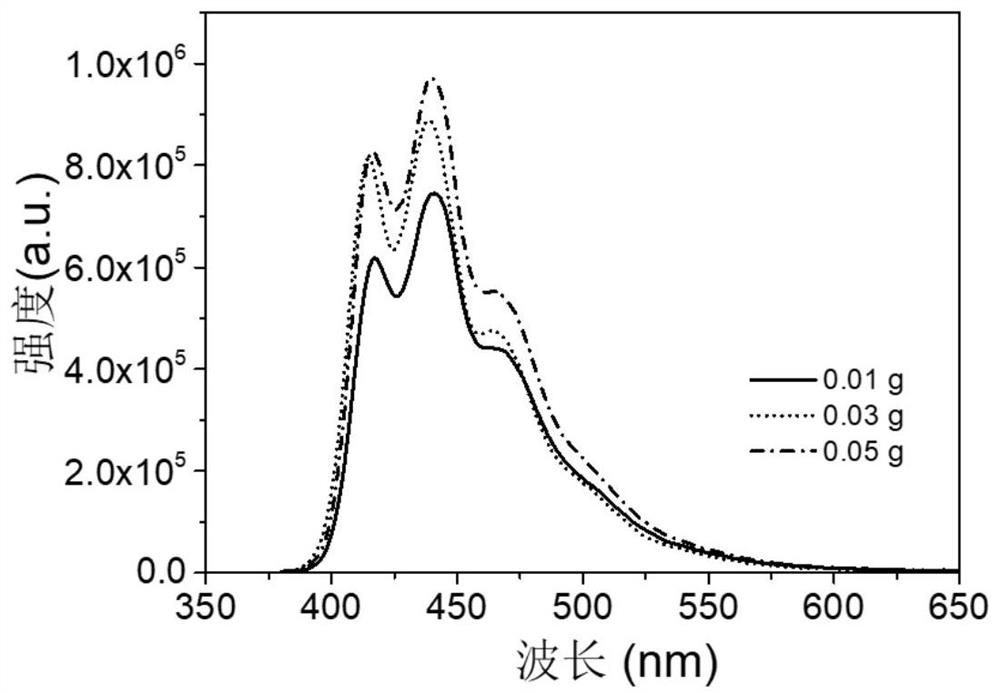

Modified vanadium dioxide composite film and preparation method thereof

PendingCN113233782AImprove stabilityStrong UV Absorbing PropertiesLuminescent paintsVanadium dioxideComposite film

The invention provides a modified vanadium dioxide composite film and a preparation method thereof, and belongs to the technical field of building energy conservation. The preparation method comprises the following steps: 1) preparing the modified vanadium dioxide-polymer coating; (2) preparing a fluorescent organic small molecule-polymer coating; (3) preparing a polymer coating; and 4) preparing the modified vanadium dioxide composite film. The preparation method is simple and easy to implement and suitable for industrial production, and the intelligent temperature control glass prepared based on the scheme can be widely applied to building doors and windows. The prepared terminal product, namely the modified vanadium dioxide composite film, can regulate and control the sunlight intake according to the change of the external temperature, and plays a role in regulating and controlling the interior of a building to be warm in winter and cool in summer.

Owner:UNIV OF JINAN

Rapid oil-blending method

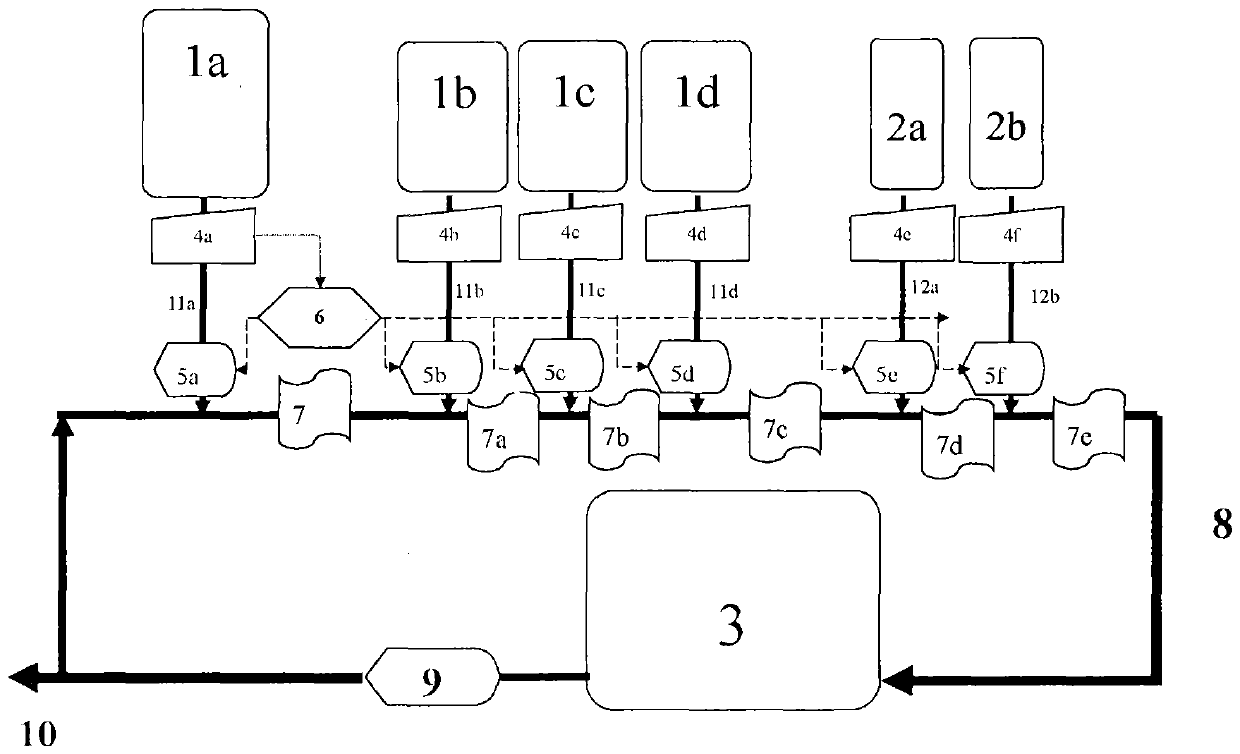

ActiveCN105396501AGuaranteed to be accurateChange flow rateFlow mixersMixer accessoriesProcess engineeringEngineering

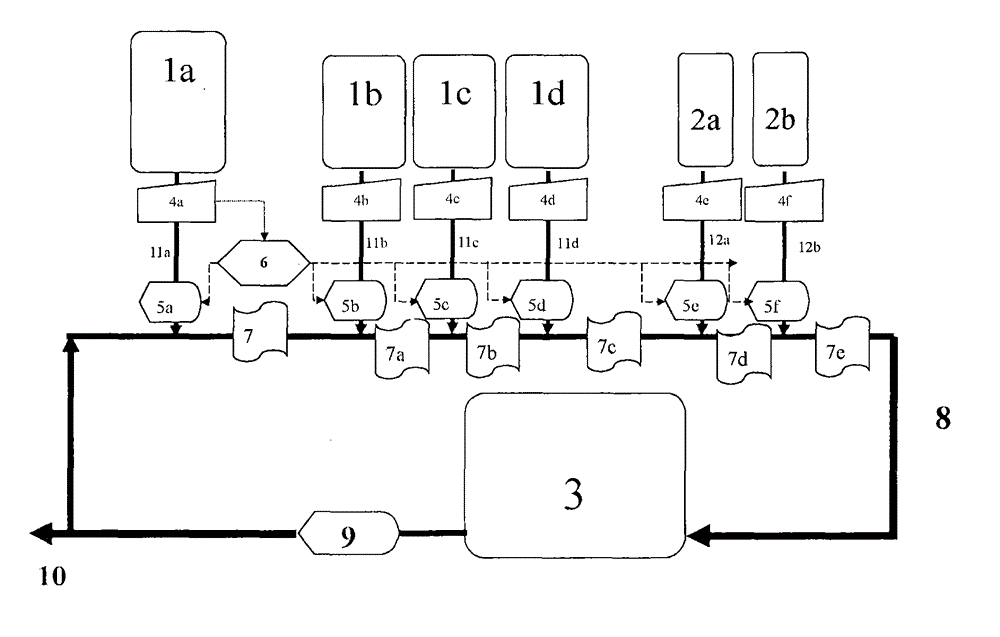

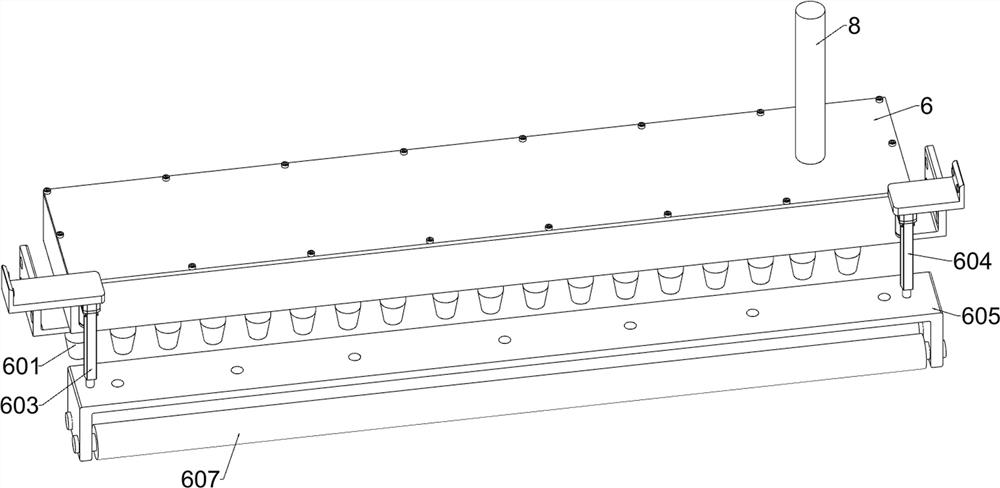

The invention provides a rapid oil-blending method and a filling system. The whole system comprises a main-component tank, component tanks, additive tanks, a blending / circulating pipeline, component pipelines, additive pipelines, flow meters for components and additives, an adjustable proportion controller, variable-frequency metering pumps, static mixers, a circulating pump, and an oil blending tank. The innovative part of the system is that a blending pipeline and a circulating pipeline of the blending tank are combined into one pipeline. Components and additives are fed into a pipeline continuously; circulation is started once oil in the blending tank is enough for circulation; and continuous feeding of the components and additives are maintained. The pipeline has two functions of pipeline circulation and pipeline blending. Meanwhile, after each component or additive enters the blending pipeline, a static mixer is arranged on the corresponding blending pipeline. According to the instantaneous flow rate of a main component and a preset ratio of oil to additive, filling amounts of other components and additives are adjusted in real time by using the variable-frequency devices.

Owner:SHANDONG QINGYISHAN PETROCHEM TECH CO LTD +1

Casting nylon composite

Owner:HENAN UNIV OF SCI & TECH

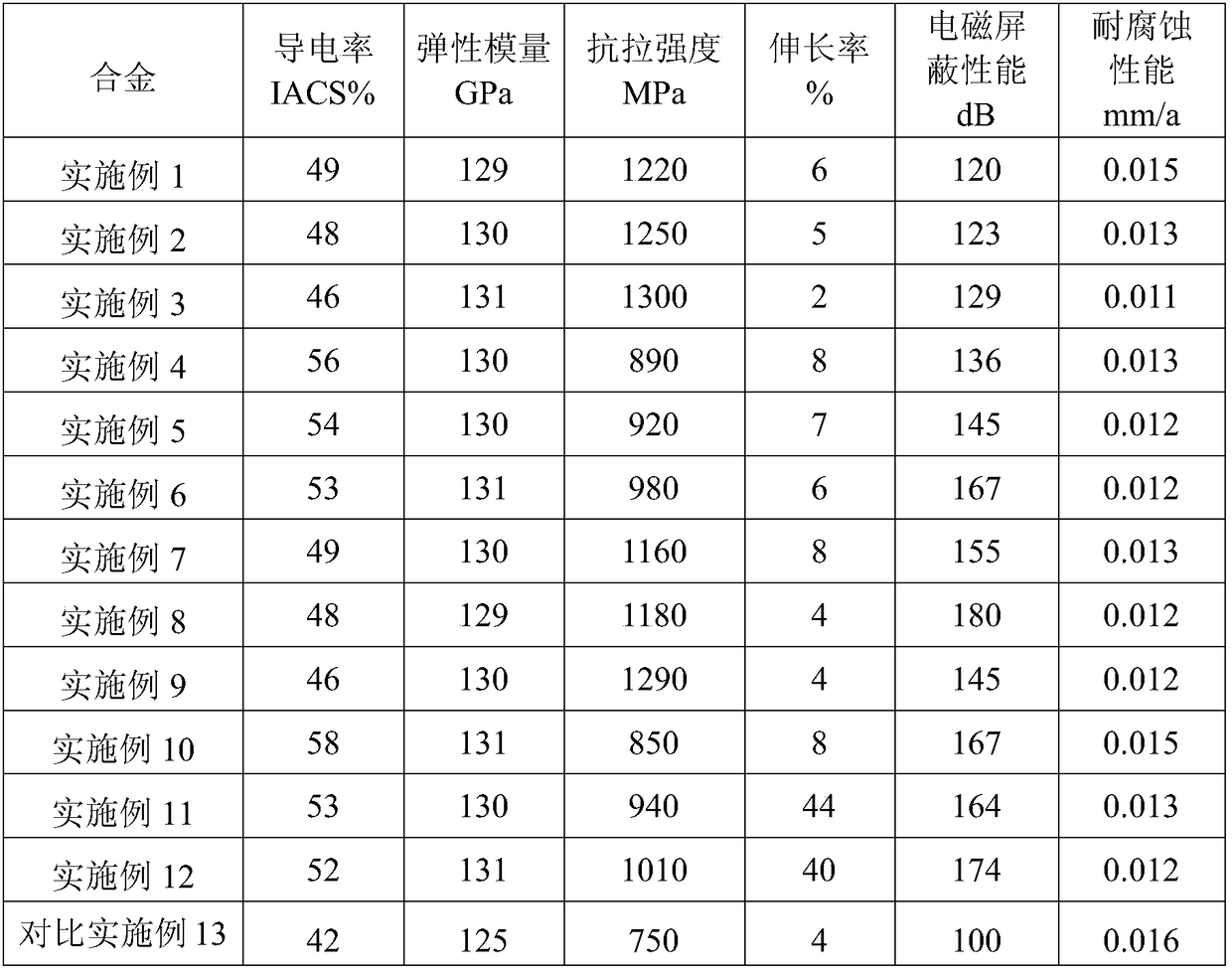

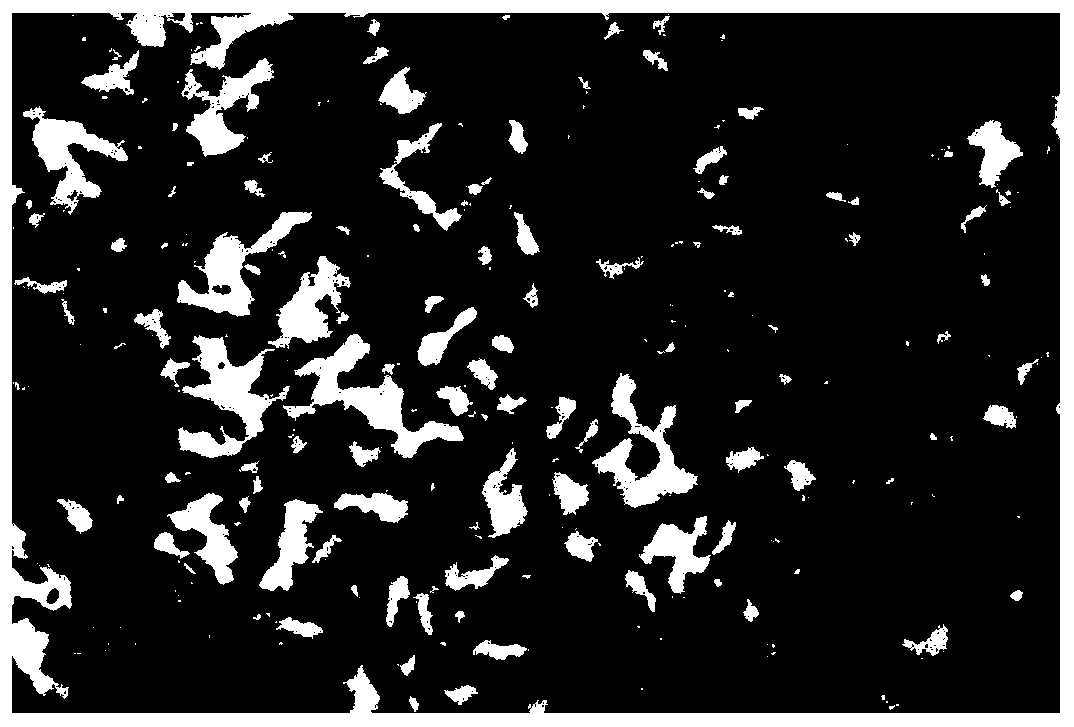

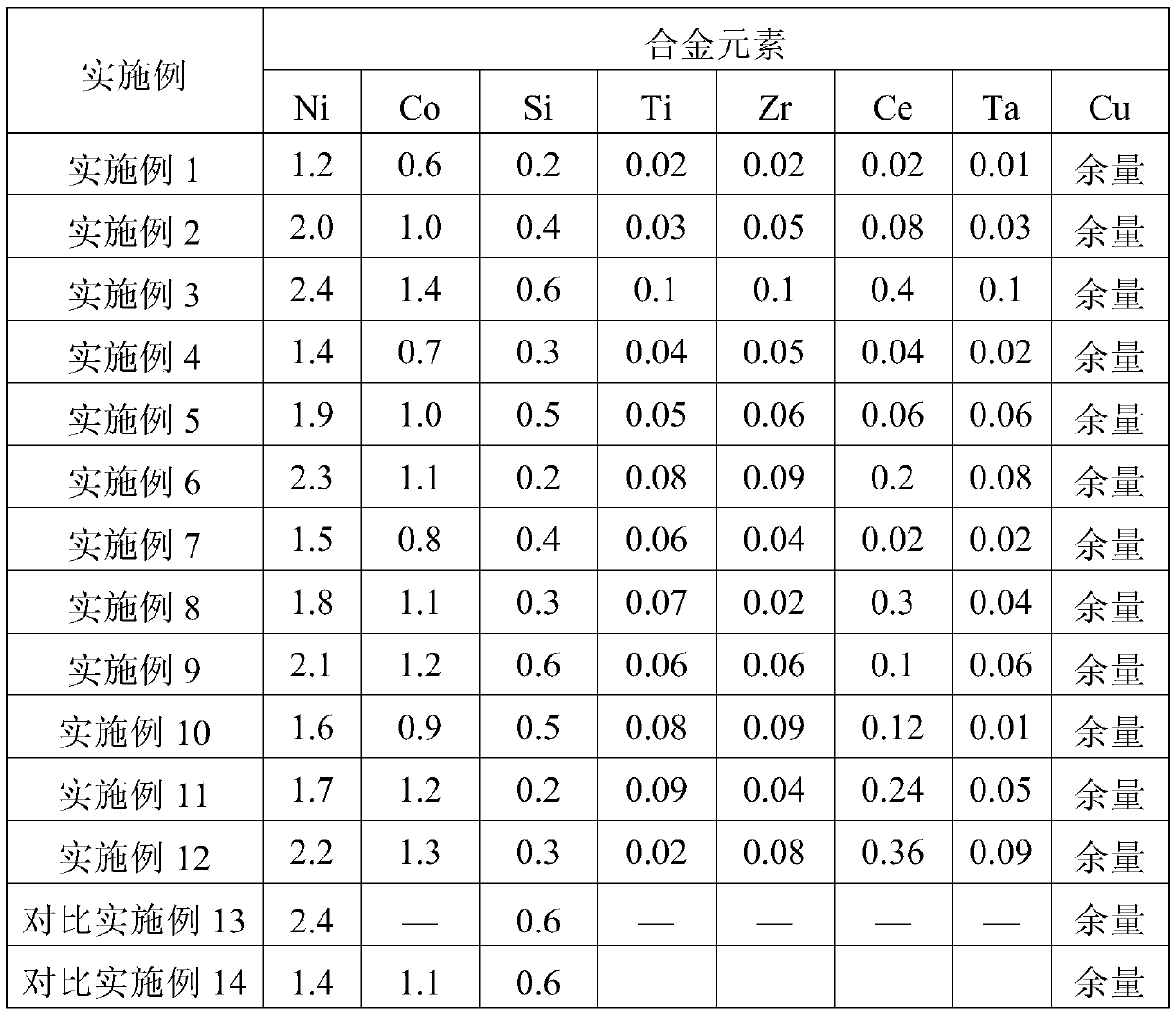

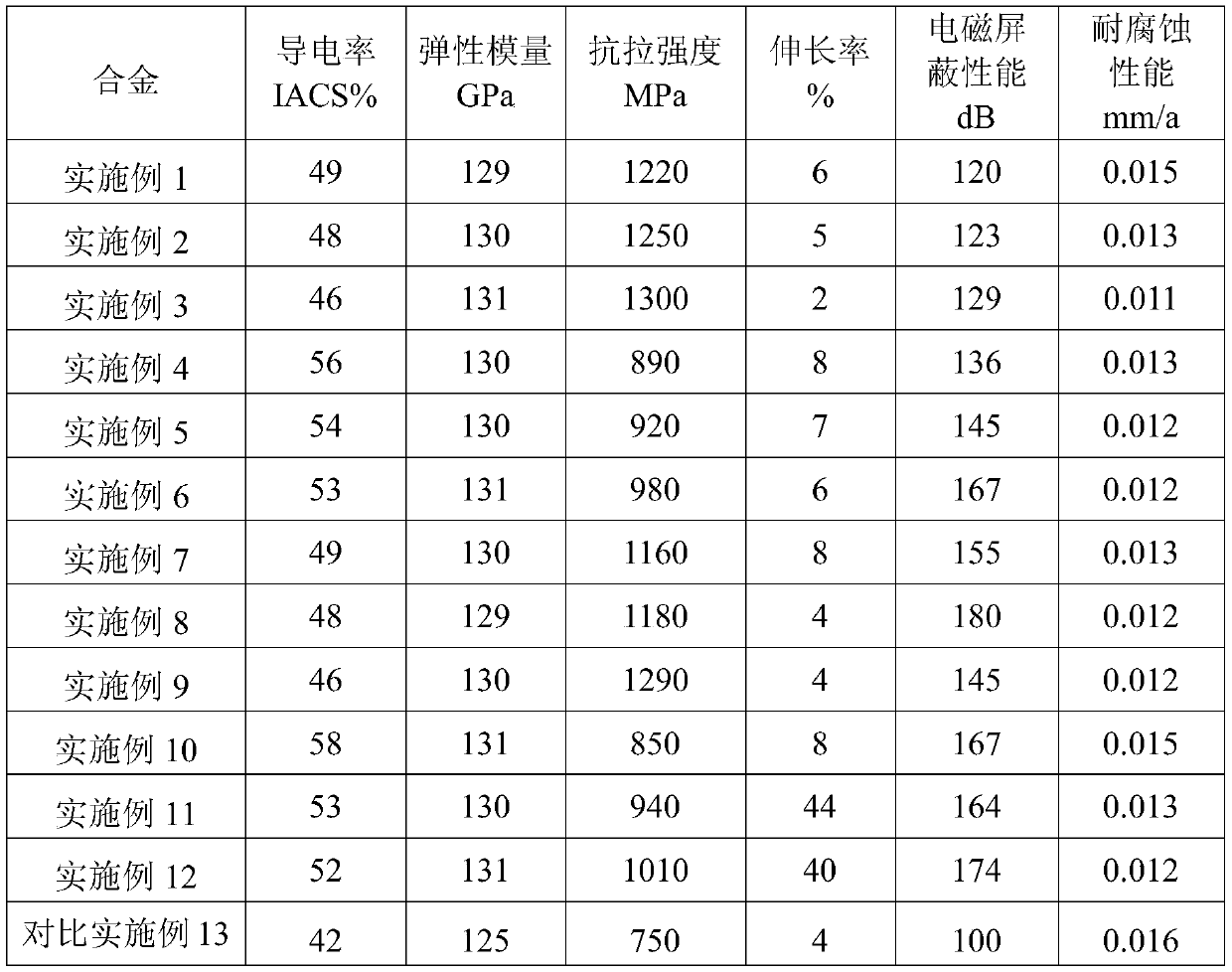

Copper alloy with circular disc-shaped precipitate and preparation method thereof

The invention belongs to the technical field of non-ferrous metal processing, particularly relates to copper alloy with circular disc-shaped precipitates and a preparation method thereof. The alloy isprepared from the following ingredients including 1.2 to 2.4 percent of Ni, 0.6 to 1.4 percent of Co, 0.2 to 0.6 percent of Si, 0.02 to 0.1 percent of Ti, 0.02 to 0.1 percent of Zr, 0.02 to 0.4 percent of Ce, 0.01 to 0.1 percent of Ta and the balance of Cu. After the deformation aging treatment on the alloy, the conductivity, the elasticity modulus, the tensile strength, the plastic elongation rate, the anti-electromagnetic-shielding performance and the anti-corrosion performance can be obviously improved; by regulating and controlling the addition of the alloy element, different properties required by the alloy can be improved; the alloy can be further applied to the fields of information industries, aquiculture, power cable, automobile electronic components and the like. The method hasthe advantages that the process is simple; the efficiency is high; the controllability is realized; the industrialization production is facilitated.

Owner:GRIMAT ENG INST CO LTD

Ramming material and preparation method thereof

The invention discloses a ramming material and a preparation method thereof. The ramming material mainly comprises the following raw materials by weight: 30-70% of silicon carbide, 25-65% of white coal or electrically calcined white coal, 9-20% of graphite powder or carbon powder, 0.5-8% of sulfur powder, 0.3-2% of paraffin oil, and 13-20% of an adhesive. The preparation method of the ramming material comprises the step of mixing and stirring the raw materials in proportion for more than 40 minutes. The ramming material does not need to be heated and fried during construction operation, is notinfluenced by weather temperature, and can be operated and constructed at the natural environment temperature of -30 DEG C to 40 DEG C. The ramming material has the excellent characteristics of oxidation resistance and acid corrosion resistance, and can be used as a mineral wool furnace lining material and an acid submerged arc furnace lining material. The ramming material disclosed by the invention is relatively long in storage life, the light shielding quality guarantee period is 400 days, and the ramming material is not caked and agglomerated due to the change of climate temperature.

Owner:冷水江市湘鲁石墨制造有限公司

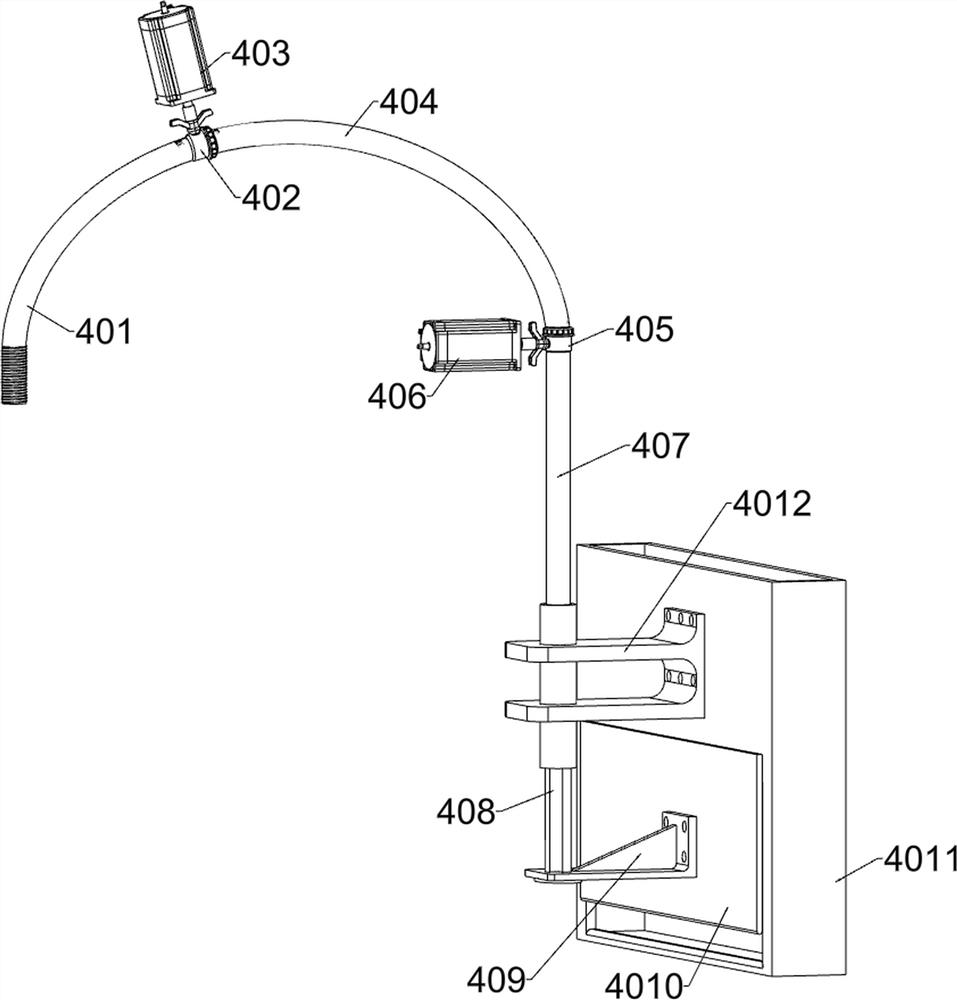

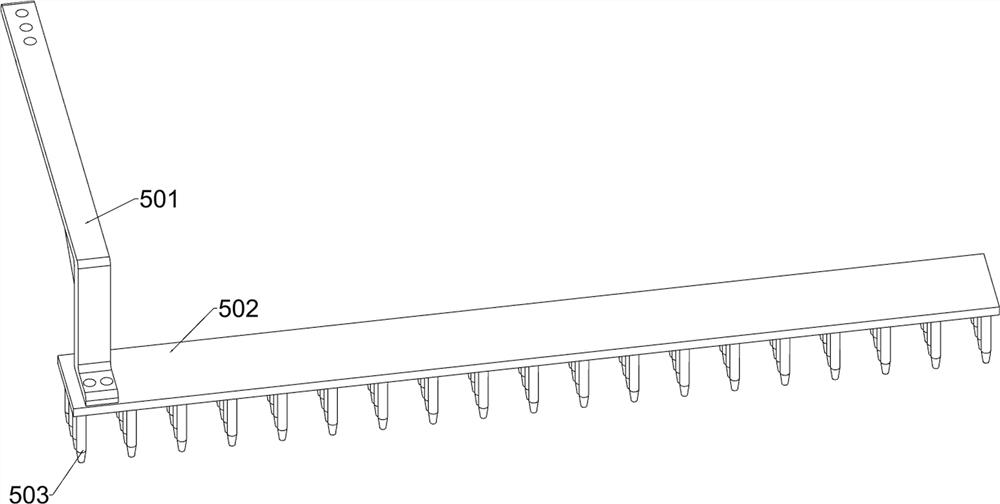

Macromolecular viscose adding device for air pressure type road waterproofing treatment

The invention relates to the field of macromolecules, in particular to an macromolecular viscose adding device for air pressure type road waterproofing treatment. The technical problem to be solved by the invention is to provide the macromolecular viscose adding device for air pressure type road waterproofing treatment, which comprises a detection assembly, a flattening assembly and the like; wherein the left end of a protective frame is fixedly connected with the first bolt fixing plate; and the detection assembly is fixedly connected with the flattening assembly. According to the non-woven fabric surface flatness detection device and method, the non-woven fabric surface flatness can be detected through an air pressure type method; meanwhile, the alternate adding amount of the non-woven fabric surface under different conditions can be changed by means of air pressure value changes in the detection process, and therefore, it is ensured that bonding between the non-woven fabric and asphalt is firm, the waste amount of macromolecule viscose is reduced; that is to say, waterproof effect of the road is ensured while the production cost is effectively reduced.

Owner:重庆派领地面防滑工程技术有限公司

A kind of quick blending method of oil products

ActiveCN105396501BChange flow rateChange the amount addedFlow mixersMixer accessoriesProportional controlLine tubing

The invention provides a rapid oil-blending method and a filling system. The whole system comprises a main-component tank, component tanks, additive tanks, a blending / circulating pipeline, component pipelines, additive pipelines, flow meters for components and additives, an adjustable proportion controller, variable-frequency metering pumps, static mixers, a circulating pump, and an oil blending tank. The innovative part of the system is that a blending pipeline and a circulating pipeline of the blending tank are combined into one pipeline. Components and additives are fed into a pipeline continuously; circulation is started once oil in the blending tank is enough for circulation; and continuous feeding of the components and additives are maintained. The pipeline has two functions of pipeline circulation and pipeline blending. Meanwhile, after each component or additive enters the blending pipeline, a static mixer is arranged on the corresponding blending pipeline. According to the instantaneous flow rate of a main component and a preset ratio of oil to additive, filling amounts of other components and additives are adjusted in real time by using the variable-frequency devices.

Owner:SHANDONG QINGYISHAN PETROCHEM TECH CO LTD +1

Airgel-modified polypropylene, ultra-light thermal insulation melt-blown nonwoven fabric and preparation method thereof

ActiveCN108677380BChange the amount addedNo sheddingFilament/thread formingMonocomponent polypropylene artificial filamentPolymer scienceThermal insulation

Owner:江苏弘源淏尔新材料科技有限公司

1-3 structure huge magnetoelectric material and preparing process thereof

InactiveCN100364129CImprove magnetoelectric propertiesEasy to makeDevice material selectionGalvano-magnetic material selectionElectricityConversion coefficients

This invention relates to a 1-3 structured huge magnet electric material and its preparation method. The material is composed of piezoelectric ceramics, magnetostriction materials and a high-molecular binding agent, among which, one of the dimension of the piezoelectric ceramics is greater than the other two shaped in a long column and distributed in a 3-D matrix composed of the magnetostriction materials powder and the high-molecular binding agent. This 1-3 structured material has high and stable magnetoelectric conversion coefficient, which can be regulated by altering contents of the piezoelectric ceramics.

Owner:TSINGHUA UNIV

Automatic ball feeder

The invention provides an automatic ball feeder. The automatic ball feeder comprises a conveying assembly and a driving assembly. The conveying assembly is composed of a ball storage tank of which thebottom is provided with slideways inclined by a certain angle, a movable baffle mounted on the lower portion of the slideways and a transmission mechanism arranged in the movable baffle and used forconveying steel balls to a ball receiving hopper. The end, facing the ball receiving hopper, of the bottom of the movable baffle is provided with a ball outlet. A blocking part is mounted on the jointbetween the sideway and the transmission mechanism. The driving assembly is composed of a motor connected with the transmission mechanism through a transmission shaft and a coupling arranged betweenthe motor and the transmission shaft. The automatic ball feeder is high in conveying efficiency, high in running stability, capable of effectively preventing bridging and preventing the balls from getting jammed and also capable of saving motor power, has the overload protection effect, ensures the quite high filling rate, reduces loss of equipment, substantially reduces the cost and meanwhile, further improves the working efficiency.

Owner:BENGANG STEEL PLATES

Composite molecular sieve carbon film based on phenolic resin-based carbon tube as support body, preparation method and application thereof

ActiveCN112619442ALow costReduce manufacturing costSemi-permeable membranesDispersed particle separationComposite materialMolecular sieve

The invention discloses a composite molecular sieve carbon film based on a phenolic resin-based carbon tube as a support body and a preparation method thereof. The composite molecular sieve carbon membrane comprises a carbon tube support body and a carbon membrane separation layer, the carbon membrane separation layer is attached to the outer surface or the inner surface of the carbon tube support body, the carbon tube support body is of a carbon-containing porous tubular structure, the average pore diameter is 0.05-0.5 micron, the porosity is 20-80%, the average pore diameter of the carbon membrane separation layer is smaller than 10nm, and the porosity is 20-40%. And the carbon tube support body and the carbon membrane separation layer are both made of a carbon material. As a carbon tube support body precursor and a separation layer precursor are jointly subjected to curing and carbonization treatment to obtain the support body and the separation layer which are both made of carbon materials, the problem that the membrane performance is reduced due to a two-phase gap in a composite carbon membrane in the prior art is solved, the preparation process is simple, the process parameters are controllable, the preparation cost is saved by about 50%, and the permeation flux of the membrane performance is improved by more than 20%.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of fluffy nanometer yttrium oxide powder

ActiveCN104326500BSmall granularityLow preparation temperatureRare earth metal oxides/hydroxidesMaterial nanotechnologyInorganic saltsRare earth ions

The invention discloses a preparation method of fluffy nano yttrium oxide powder, and belongs to the technical field of synthesis of superfine nano powder. The preparation method comprises steps of firstly mixing yttrium-containing inorganic salt, de-ionized water and a complexing agent, and uniformly stirring at room temperature to obtain slurry containing yttrium, wherein the weight ratio of the yttrium-containing inorganic salt to the complexing agent is 8 to (0.5-10), and when a target product is RE: Y2O3, the yttrium-containing inorganic salt is doped with rare earth ions; calcining the slurry or sol or xerogel obtained from the slurry at 400-900 DEG C, and decomposing sufficiently to obtain fluffy Y2O3 or RE: Y2O3 nano powder. By preparing the nano yttrium oxide which is small in agglomeration, small in grain size and narrow in distribution by the novel complexing agent through a calcining method, the preparation method disclosed by the invention can effectively avoid later treatment such as breaking and grinding on a prepared sample. The method is simple to operate, low in synthesis temperature, short in cycle and easy for industrialization; the method is beneficial for preparing multi-element doped composite yttrium oxide nano powder; and by controlling addition of the complexing agent, nano powder distributed in different grain size intervals can be prepared.

Owner:HUAZHONG UNIV OF SCI & TECH

Copper alloy with disc-shaped precipitates and preparation method thereof

The invention belongs to the technical field of non-ferrous metal processing, particularly relates to copper alloy with circular disc-shaped precipitates and a preparation method thereof. The alloy isprepared from the following ingredients including 1.2 to 2.4 percent of Ni, 0.6 to 1.4 percent of Co, 0.2 to 0.6 percent of Si, 0.02 to 0.1 percent of Ti, 0.02 to 0.1 percent of Zr, 0.02 to 0.4 percent of Ce, 0.01 to 0.1 percent of Ta and the balance of Cu. After the deformation aging treatment on the alloy, the conductivity, the elasticity modulus, the tensile strength, the plastic elongation rate, the anti-electromagnetic-shielding performance and the anti-corrosion performance can be obviously improved; by regulating and controlling the addition of the alloy element, different properties required by the alloy can be improved; the alloy can be further applied to the fields of information industries, aquiculture, power cable, automobile electronic components and the like. The method hasthe advantages that the process is simple; the efficiency is high; the controllability is realized; the industrialization production is facilitated.

Owner:GRIMAT ENG INST CO LTD

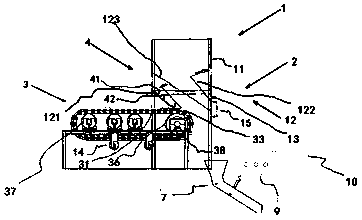

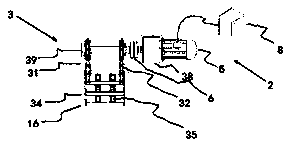

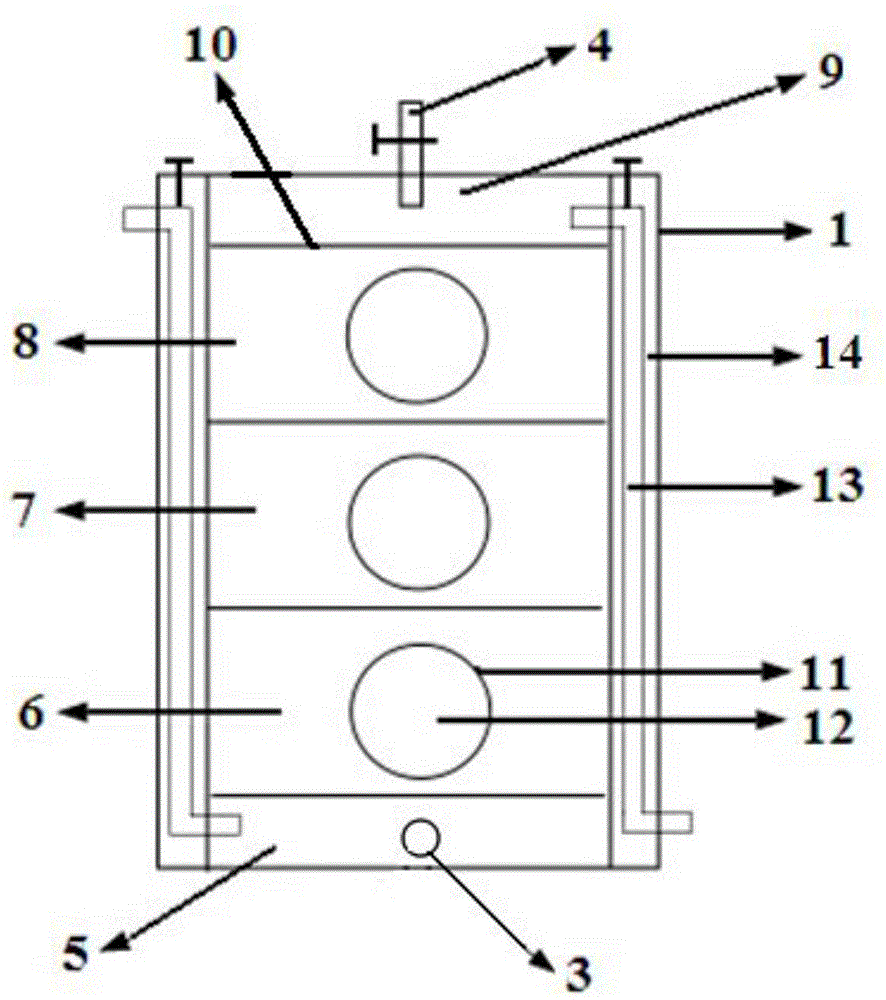

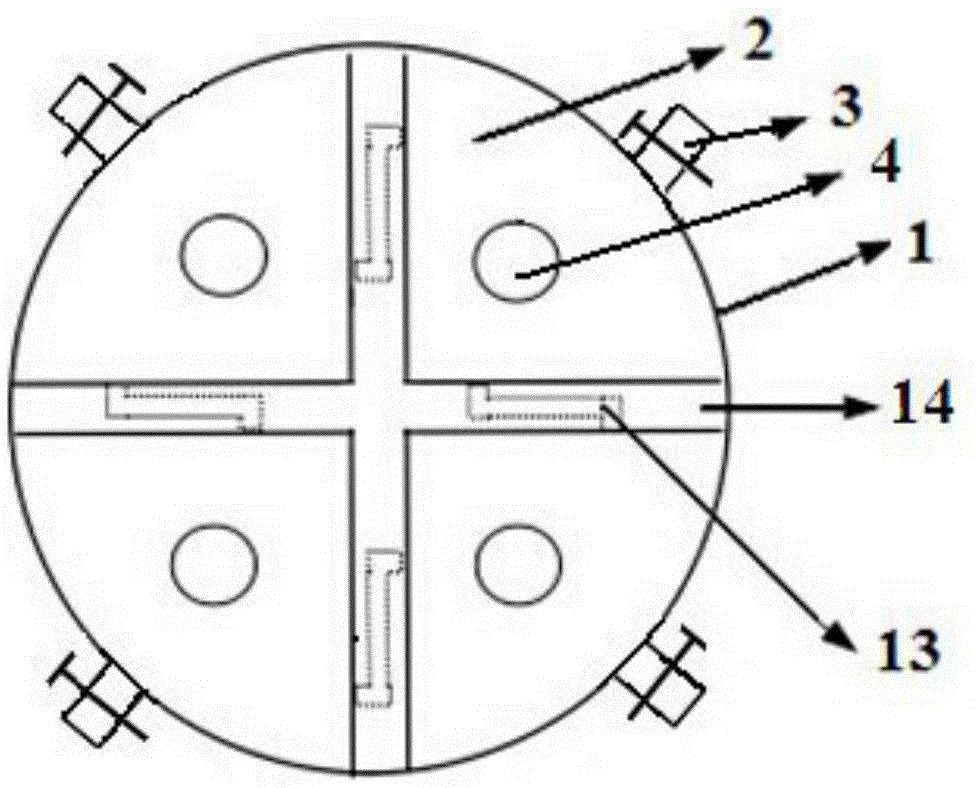

Non-chain df/hf laser discharge products miniaturized dry processing device

InactiveCN104474855BReduce volumeReduce weightDispersed particle separationLaser processingMiniaturization

The invention discloses a non-chain-type DF / HF laser discharge product small-scale dry-treatment device and belongs to the technical field of laser discharge product treatment. The device solves the problem that the existing laser tail gas treatment device has a large structure, complex adsorbent loading and unloading processes influencing with each other, is inconvenient for storage and transport, and produces environmental pollution. The device comprises a metal casing and one or more sealed purification units. Each one of the one or more sealed purification units comprises a gas inlet pipe, a gas outlet pipe, and an adsorbent storehouse chamber composed of a first transition storehouse chamber, a first storehouse chamber, a second storehouse chamber, a third storehouse chamber and a second transition storehouse chamber orderly arranged from bottom to top. The metal casing is respectively provided with filler openings communicated with the first storehouse chamber, the second storehouse chamber and the third storehouse chamber. The filler openings are respectively used for filling and discharging the adsorbent in the first storehouse chamber, the second storehouse chamber and the third storehouse chamber. Sealing covers for sealing the filler openings are arranged on the filler openings. The device has the advantages of thorough product treatment, small equipment volume, light weight, operation easiness, maintenance convenience and no secondary pollution waste water.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

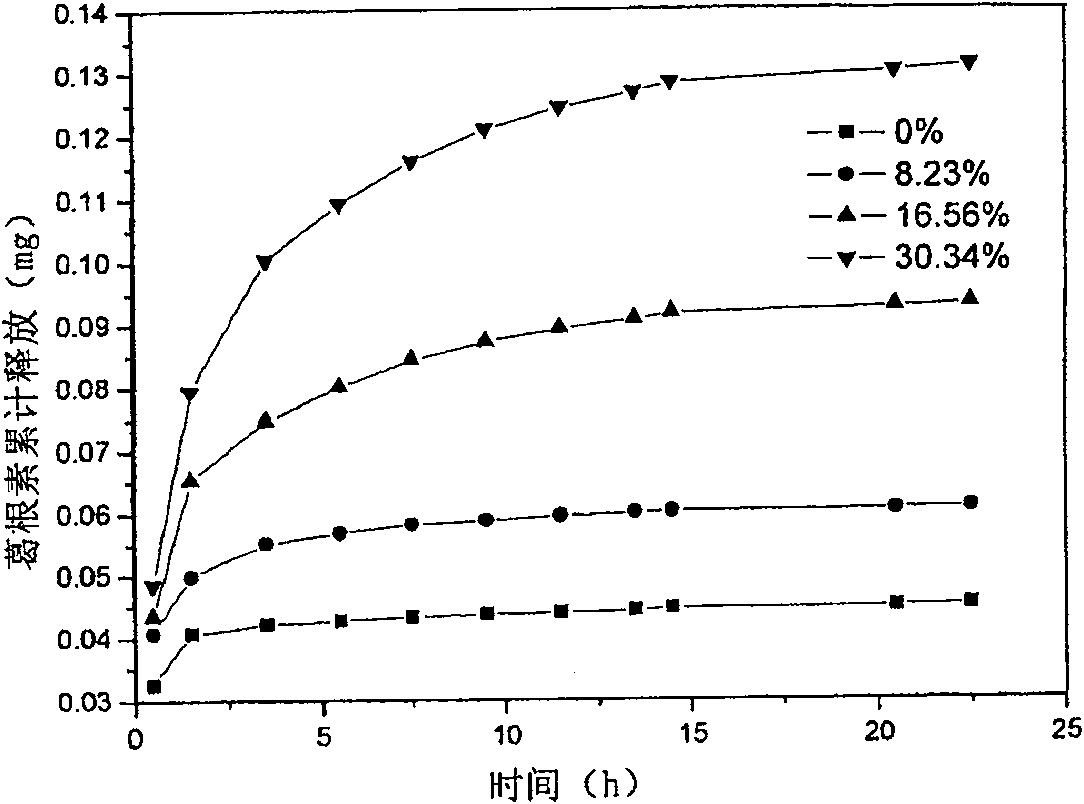

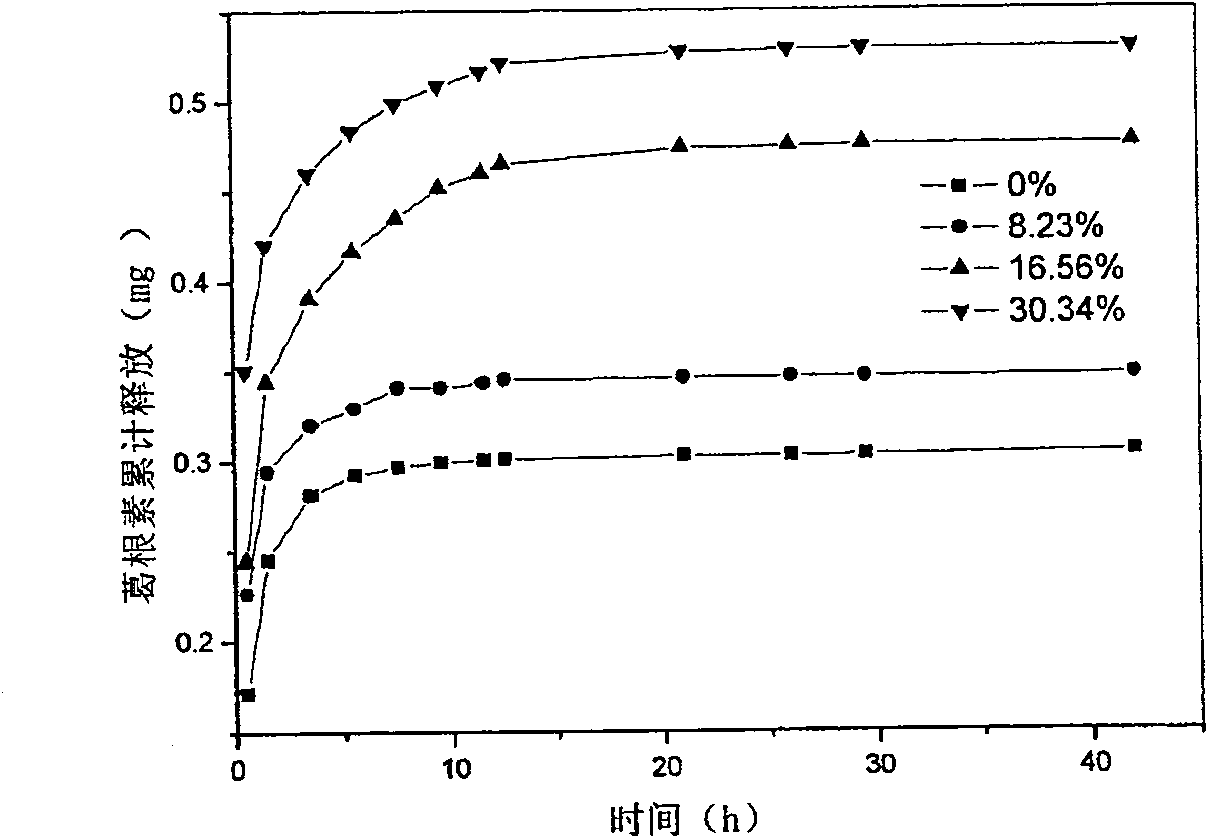

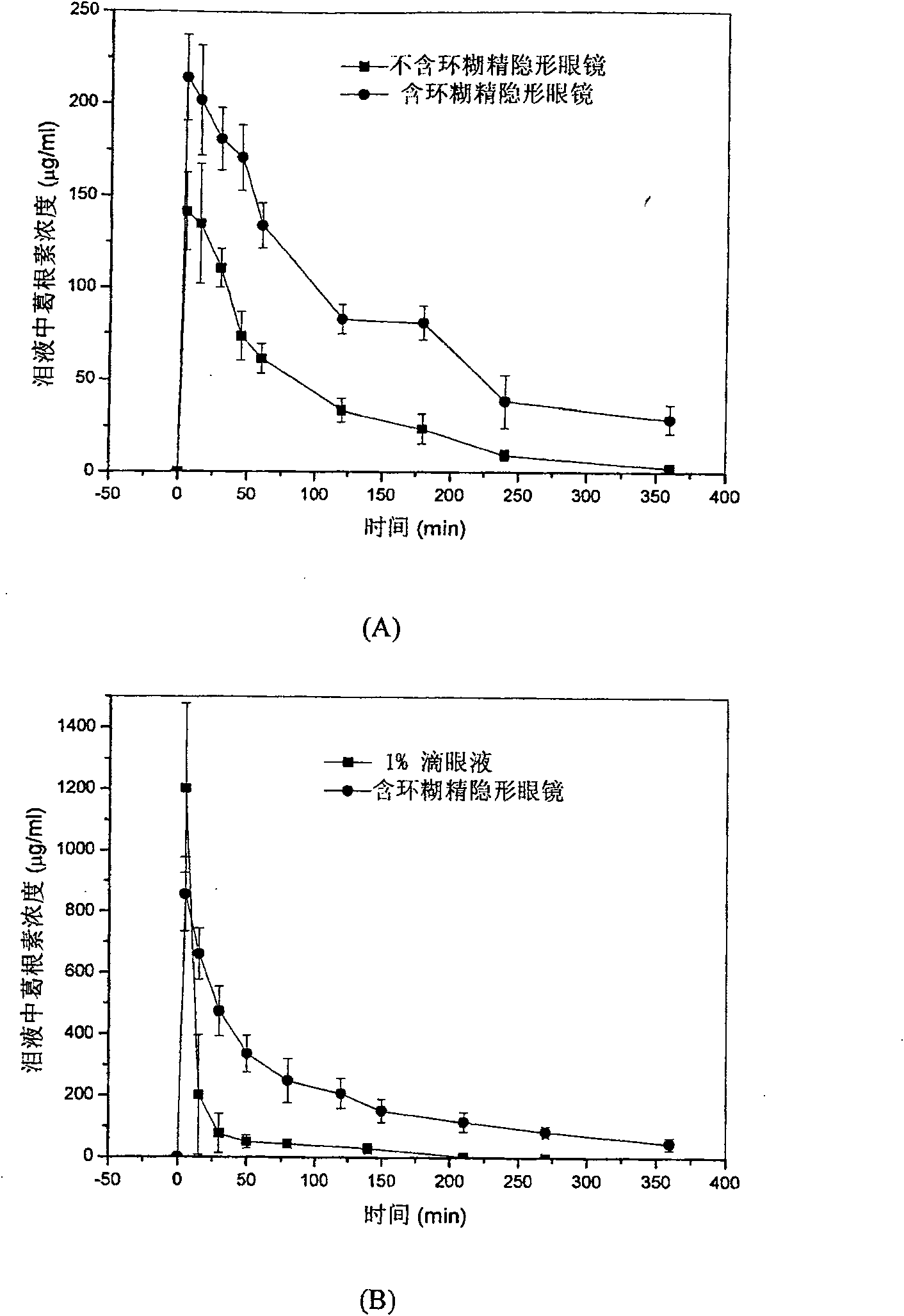

Medicine-carrying contact lens and preparation method thereof

InactiveCN100596332CEasy to fixChange the amount addedOrganic active ingredientsSenses disorderPuerarinDrug release

The invention relates to a drug-loaded contact lenses and a corresponding preparation method. The drug-loaded contact lenses are obtained firstly through UV-curing or heat-curing and then through drug-liquid immersion. The drug-loaded contact lenses can be particularly defined as a combination of a contact lenses material containing cyclodextrin and drug molecules and comprise the contact lenses formed by combining a crosslinked polymer hydrogel formed by copolymerizing mono-substituted cyclodextrin monomers, polymerization monomers and crosslinkers with one kind or a plurality of acetazolamide, methazolamide, puerarin or prostaglandin. The characteristic of forming inclusion compounds between the cyclodextrin molecules and drug molecules is adopted to increase the quantity of loaded drugsso as to reduce the stimulation to eyes by drugs and control the drug release speed for eye diseases of curing glaucoma, etc.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com