Non-chain df/hf laser discharge products miniaturized dry processing device

A discharge product, dry treatment technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of complicated loading and unloading of adsorbents, inconvenient storage and transportation, mutual influence, etc., achieving light weight and convenient maintenance. , easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

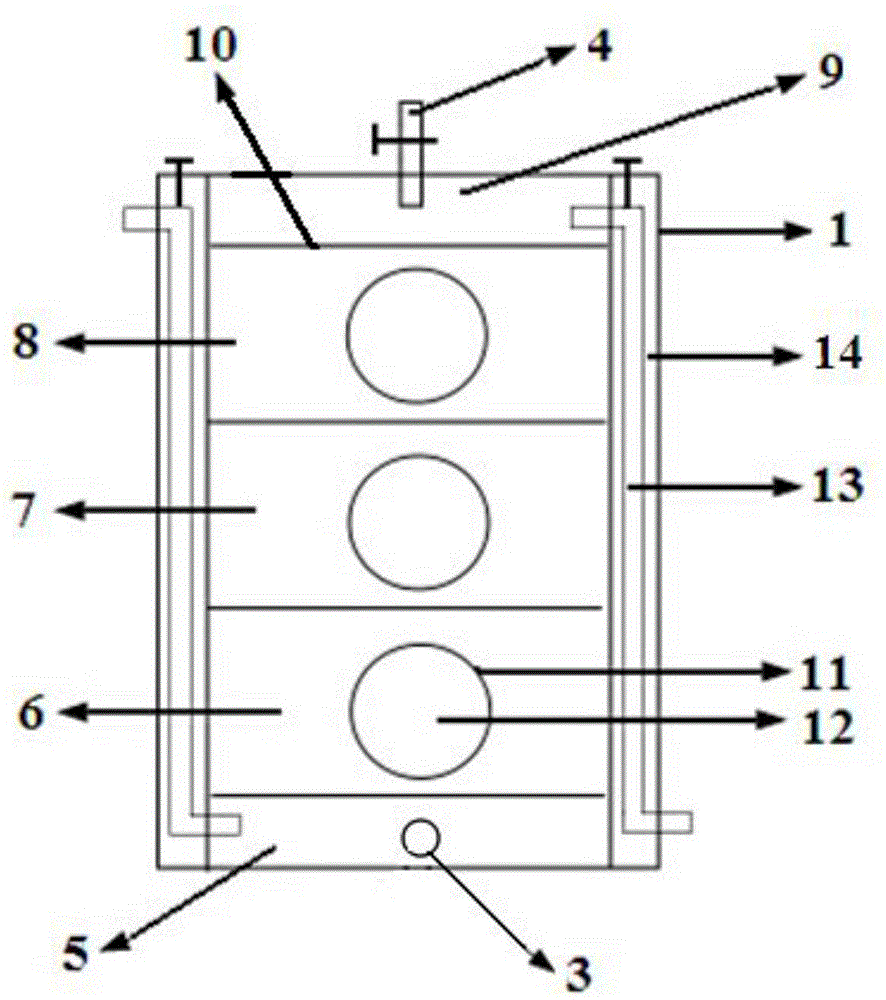

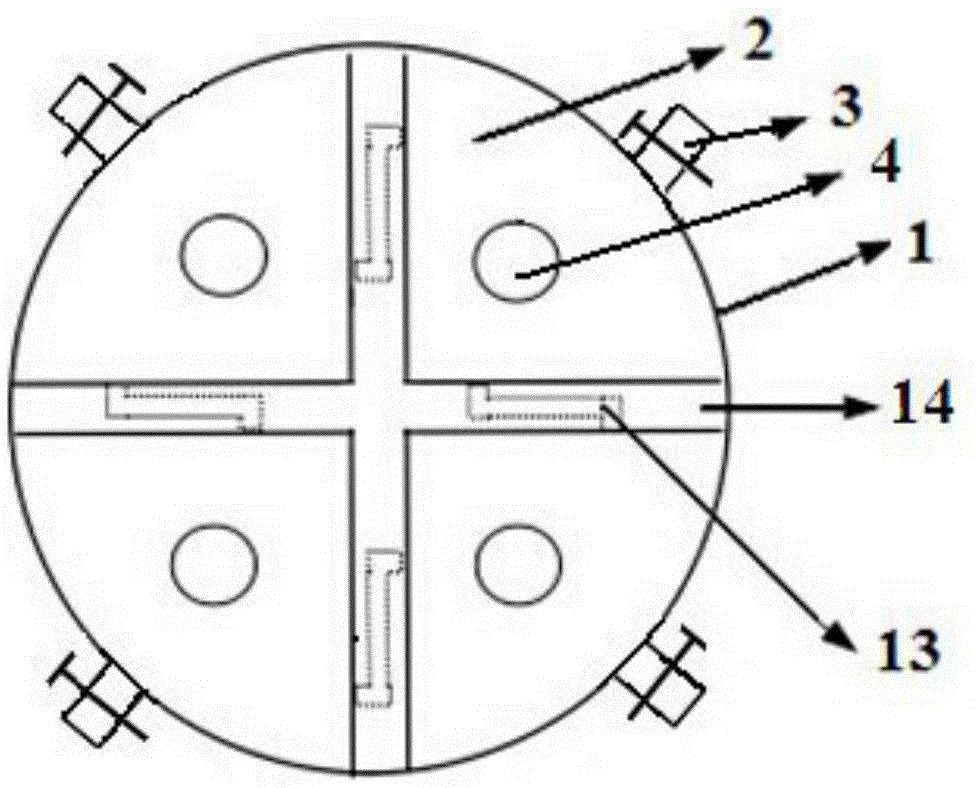

[0028] Such as figure 1 , 2 As shown, the non-chain DF / HF laser discharge product miniaturized dry processing device includes: a metal shell 1 and more than one purification unit 2 . Wherein, each purification unit 2 is a sealed structure, and each purification unit 2 is composed of an adsorbent chamber, an intake pipe 3 and an exhaust pipe 4, the adsorbent chamber is set in the inner cavity of the metal shell 1, and the adsorbent The warehouse consists of the first transition chamber 5, the first chamber 6, the second chamber 7, the third chamber 8 and the second transition chamber 9 arranged in sequence from bottom to top. The first transition chamber 5 is used to accommodate The discharge product introduced by the intake pipe 3, the second transition chamber 9 is used to accommodate the discharge product that will be removed from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com