Rapid oil-blending method

A technology for blending and oil products, which is applied in the field of rapid blending methods for oil products, can solve problems such as complex systems, expensive control systems, and many control points, and achieve accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042] The specific implementation of the present invention can be carried out in the following order:

[0043] 1. According to the properties of the finished product to be blended, select the appropriate component oil, and calculate the mutual ratio and blending amount of the blending components.

[0044] 2. Adjust the frequency converter / pump, adjust the speed of the pump by adjusting the motor frequency converter, set the flow rate of the main component, PLC calculates the frequency conversion data of the remaining components and additives, adjust the pump by adjusting the motor frequency converter The speed of the sub reaches the calculated rated value.

[0045] 3: When the liquid level in the blending tank rises to 5-10% of the total liquid level, turn on the circulation pump, set the flow rate to 0.5-5 times the feed volume of the blending tank, and start the circulation.

[0046] 4: When the feeding amount of the main component reaches the set value, stop the feeding o...

Embodiment 1

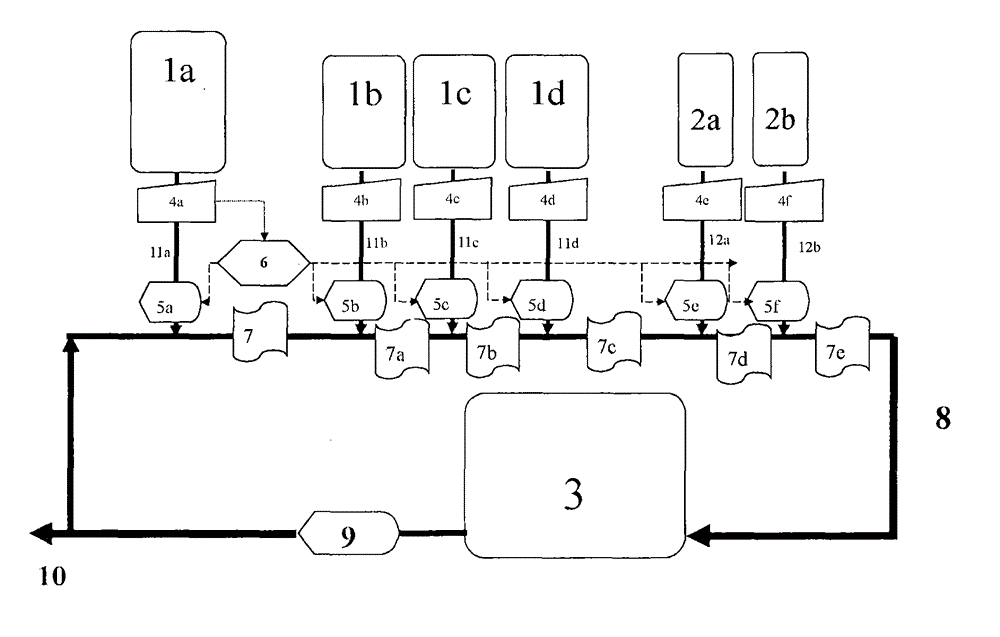

[0049] According to the blending method that the present invention proposes, blend No. 90 unleaded gasoline. First, the catalytic gasoline is set as the main component, and the catalytic gasoline that can meet the blending requirements is stored in the tank (1a). The reformed gasoline is stored in the arrangement tank (1b), the alkylated gasoline is stored in the tank (1c), the MTBE is stored in the tank (1d), the antiknock agent MMT is stored in the additive tank (2a), and the additive tank (2b ) contains antioxidants. The oil adjustment process is as follows:

[0050] 1. According to the properties of the finished product to be blended, select the appropriate component oil, and calculate the mutual ratio and blending amount of the blended components

[0051]2. Set the main flow value of the main component catalytic gasoline, 100 cubic meters per hour, and transmit it to the adjustable proportional controller (6) for calculation. The rotating speed of the pump is adjusted ...

Embodiment 2

[0056] According to the blending method proposed by the present invention, blend -35 low-condensation-point diesel oil. First, the hydrogenated refined diesel oil is set as the main component, and the hydrogenated refined diesel oil that can meet the blending requirements is stored in the tank (1a). Hydrocracked diesel oil is stored in the tank (1b), hydrogenated kerosene is stored in the tank (1c), catalytic diesel oil is stored in the tank (1d), pour point depressant T1804 is stored in the additive tank (2a), additive tank (2b) The diesel lubricity improver K8280C is stored inside.

[0057] The oil adjustment process is as follows:

[0058] 1. According to the properties of the finished product to be blended, select the appropriate components, and calculate the mutual ratio and blending amount of the blended components

[0059] 2. Set the main flow value of the main component hydrogenated refined diesel oil, 250 cubic meters per hour, and transmit it to the adjustable prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com