Copper alloy with disc-shaped precipitates and preparation method thereof

A technology for copper alloys and precipitates, which is applied in the field of copper alloys with disc-shaped precipitates and its preparation, can solve the problems of reducing electrical conductivity, etc., and achieve different performances, good electromagnetic shielding effects, excellent mechanical properties and corrosion resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

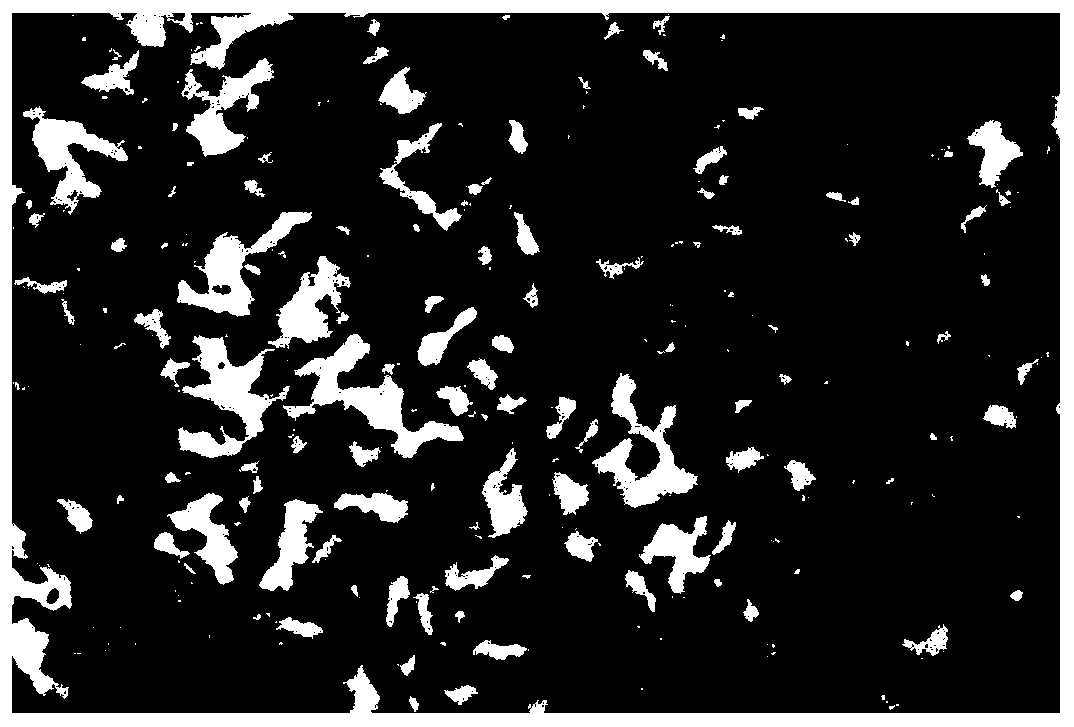

Image

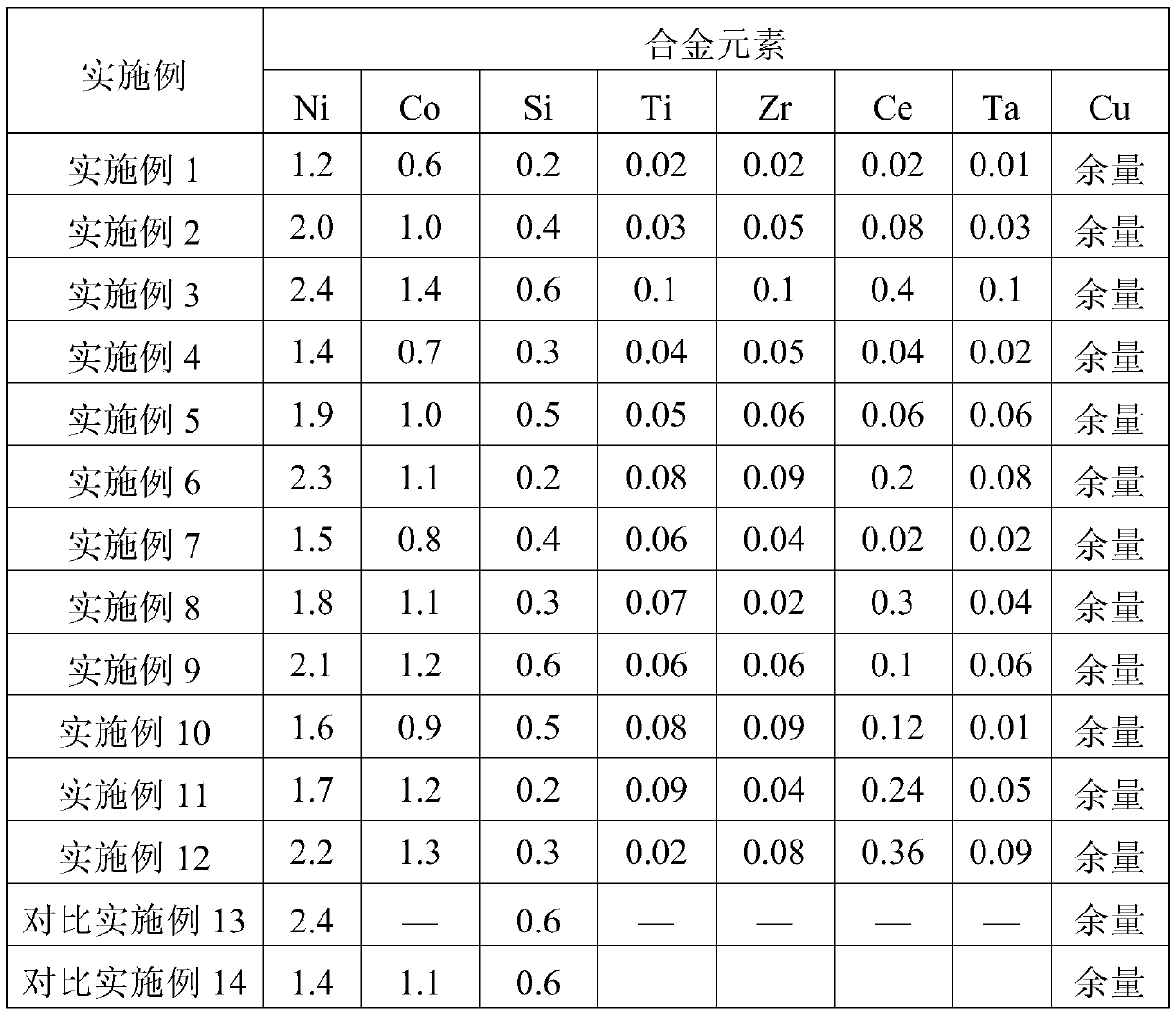

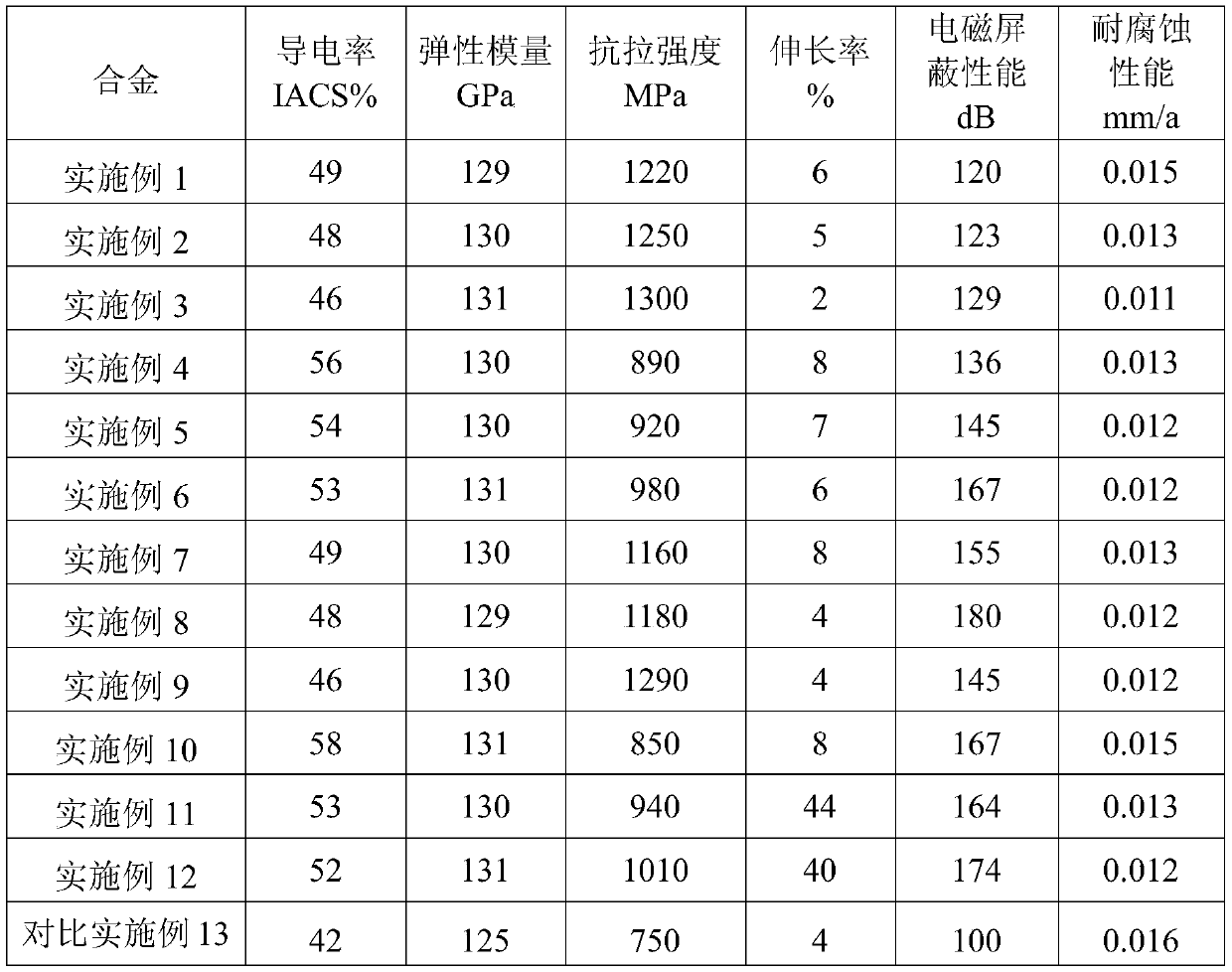

Examples

Embodiment 1

[0038] Copper alloys were prepared according to the following process flow:

[0039] (1) Melting

[0040] Add electrolytic copper, tantalum powder covered with copper foil, pure nickel, cobalt powder, and copper-silicon alloy in the order of melting in a non-vacuum induction furnace. Raise the temperature to 1300 ° C. After the melt is completely melted, keep it warm for 30 minutes. , add titanium-copper master alloy (titanium ≤ 5%), copper-cerium master alloy, and then keep the temperature for 10 minutes, then add zirconium whose surface is copper-plated; After 10 minutes, fully stir, let stand for 5 minutes, and then cast out of the furnace.

[0041] (2) solid solution

[0042] The alloy billet was heated to 900°C in a heating furnace and kept for 5 hours.

[0043] (3) Face milling

[0044] Face milling is carried out on the alloy, and the upper and lower surfaces are milled 1mm each.

[0045] (4) hot rolling

[0046] The alloy is heated, the heating temperature is 900...

Embodiment 2

[0055] Copper alloys were prepared according to the following process flow:

[0056] (1) Melting

[0057] Add electrolytic copper, tantalum powder coated with copper foil, pure nickel, cobalt powder, and copper-silicon alloy into the non-vacuum induction furnace for smelting, and raise the temperature to 1320°C until the melt is completely melted, then keep it warm for 30 minutes , adding titanium-copper master alloy (titanium ≤ 5%) and copper-cerium master alloy, then keeping the temperature for 10 minutes, and then adding zirconium whose surface is copper-plated. After fully degassing and removing impurities, at a casting temperature of 1250°C, keep warm for 10 minutes, fully stir, stand still for 5 minutes, and then cast out of the furnace.

[0058] (2) Solution treatment

[0059] The alloy billet was heated to 940°C in a heating furnace and kept for 5 hours.

[0060] (3) Face milling

[0061] Face milling is carried out on the alloy, and the upper and lower surfaces are ...

Embodiment 3

[0072] Copper alloys were prepared according to the following process flow:

[0073] (1) Melting

[0074] Add electrolytic copper, tantalum powder covered with copper foil, pure nickel, cobalt powder, and copper-silicon alloy into the non-vacuum induction furnace for smelting, and raise the temperature to 1380 ° C. After the melt is completely melted, keep it warm for 30 minutes. , adding titanium-copper master alloy (titanium ≤ 5%) and copper-cerium master alloy, then keeping the temperature for 10 minutes, and then adding zirconium whose surface is copper-plated. After fully degassing and removing impurities, at the casting temperature of 1220 ° C, after holding the heat for 10 minutes, fully stirring, standing still for 5 minutes, and then casting out of the furnace.

[0075] (2) Solution treatment

[0076] The alloy billet was heated to 980°C in a heating furnace and kept for 5 hours.

[0077] (3) Face milling

[0078] Face milling is carried out on the alloy, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| plastic strain ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com