Polyolefin elastomer peritoneal dialysis drainage bag cover cap capable of being thermoplastically processed and preparation method of polyolefin elastomer peritoneal dialysis drainage bag cover cap

A thermoplastic elastomer and thermoplastic processing technology, which is used in the fields of polymer materials, polymer blending, and polymer molding, and can solve problems such as affecting medical drug sealing, easy shrinkage and deformation, and threatening consumers' health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

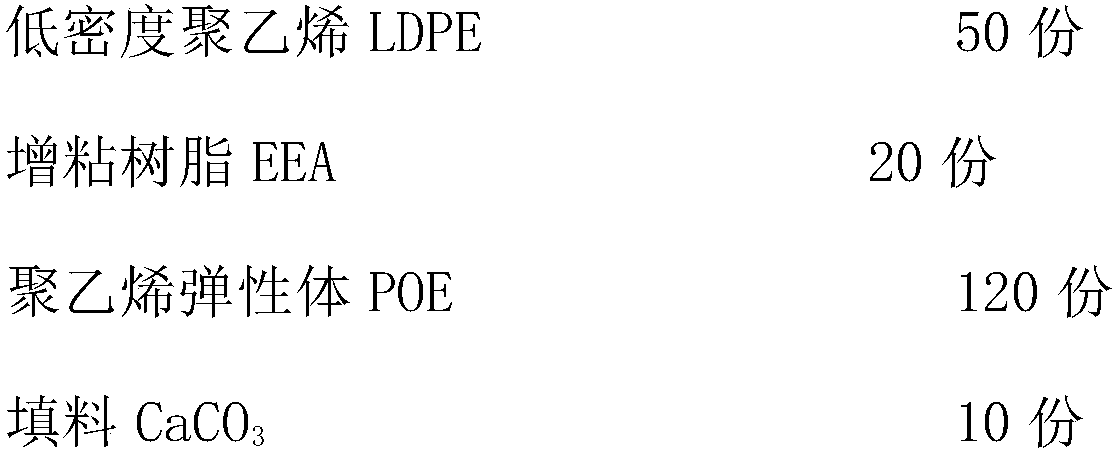

[0029] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0030]

[0031] LDPE, EEA, POE and CaCO in the above raw materials 3 Mix on high speed to obtain a homogeneous mixture. After the mixture was kneaded in an internal mixer at 150° C. for 10 minutes, a thermoplastically processable polyolefin elastomer medical cap material was obtained.

Embodiment 2

[0033] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0034] High-density polyethylene HDPE 40 parts

[0035] Tackifying resin EAA 20 parts

[0036] Styrenic thermoplastic elastomer SEBS 100 parts

[0037] Stir HDPE, EAA and SEBS in the above raw materials at high speed to obtain a uniform mixture. After the mixture was kneaded in an internal mixer at 180°C for 15 minutes, a thermoplastically processable polyolefin elastomer medical cap material was obtained.

Embodiment 3

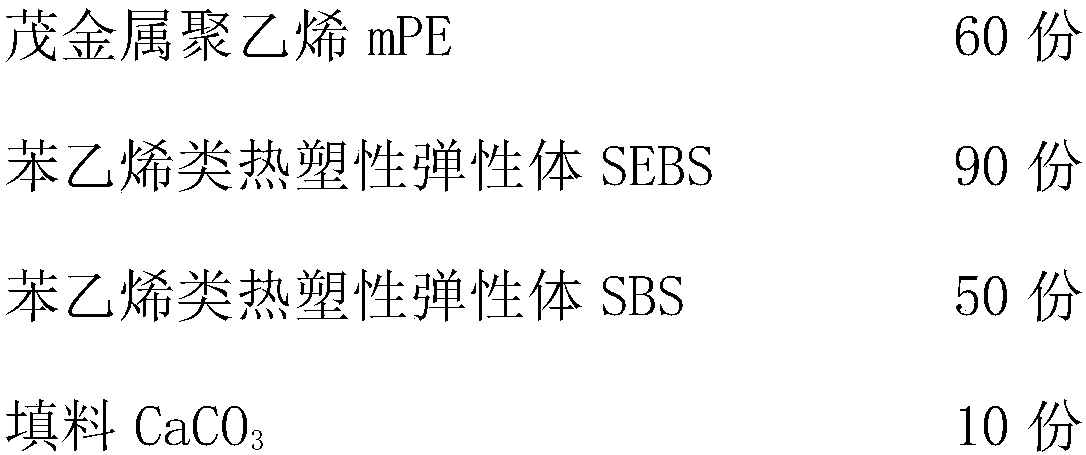

[0039] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0040] Linear low density polyethylene LLDPE 40 parts

[0041] Tackifying resin EVA 30 parts

[0042] Styrenic thermoplastic elastomer SBS 80 parts

[0043] Stir LLDPE, EVA and SBS in the above raw materials at high speed to obtain a uniform mixture. After the mixture was kneaded in an internal mixer at 160°C for 10 minutes, a thermoplastically processable polyolefin elastomer medical cap material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com