Modified PP (Polypropylene) material and application thereof

A modification and application technology, applied in the field of plastic recycling, can solve the problems of polluting resources, waste, non-degradable decay, etc., achieve excellent heat resistance, avoid environmental pollution problems and waste resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 63 parts by weight of PP regrind, 27 parts by weight of glass fiber, 4 parts by weight of calcium carbonate and 6 parts by weight of high-pressure PE, melt and mix the raw materials, and then transport the mixed melt to the extrusion Extrude from the machine for cooling and molding, cut into pellets after extrusion, mark as material 1 and test the performance of material 1. Then, the material 1 is made into the leveling angle of the electrical appliance by thermoforming.

Embodiment 2

[0023] Weigh 65 parts by weight of PP regrind, 25 parts by weight of glass fiber, 5 parts by weight of calcium carbonate, 5 parts by weight of high-pressure PE, and a small amount of flame retardant powder. The raw materials are melted and mixed, and then mixed The homogenous melt is transported to the extruder for extrusion cooling and molding. After extrusion, it is cut into pellets, marked as material 2 and the performance of material 2 is tested. Then the material 2 is made into auto parts by thermoforming.

Embodiment 3

[0025] Weigh 67 parts by weight of PP regrind, 23 parts by weight of glass fiber, 6 parts by weight of calcium carbonate and 4 parts by weight of high-pressure PE, melt and mix the raw materials, and then transport the mixed melt to the extrusion Extrude from the machine for cooling and molding, cut into pellets after extrusion, mark it as material 3 and test the performance of material 3. Then, the material 3 is made into the leveling angle of the electrical appliance by thermoforming.

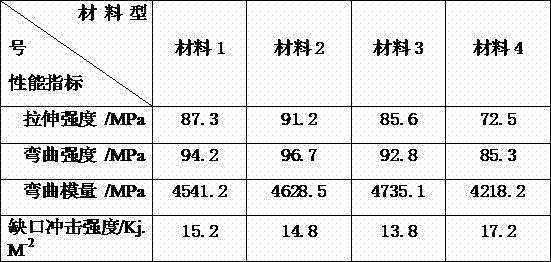

[0026] The performance of PP material (marked as material 4) modified by calcium carbonate that is commonly purchased on the market is tested. The specific test results of each material are as follows:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com