Covered stent and preparation method thereof

A stent-graft and film-covering technology, applied in the field of medical devices, can solve the problems of vascular side branch opening blockage, high restenosis rate, endothelial layer peeling, etc., and achieves low clinical stocking cost, simplified preparation process, and improved compliance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

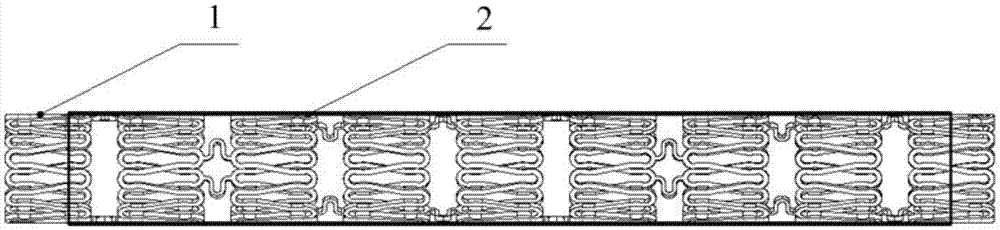

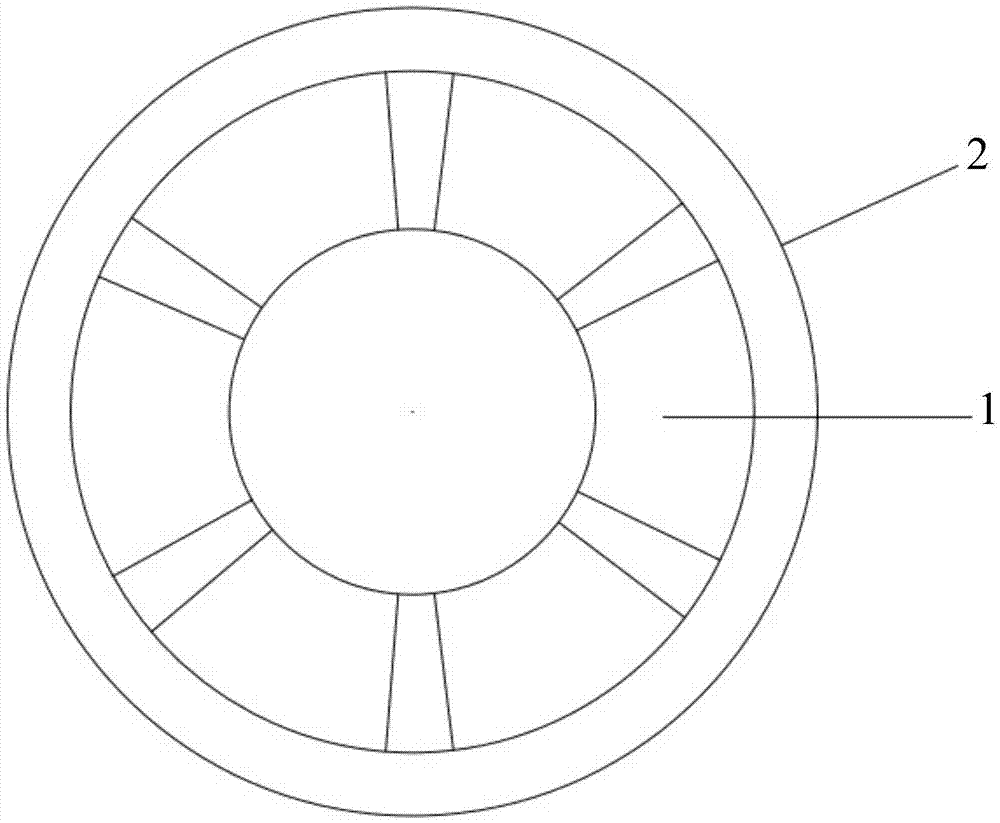

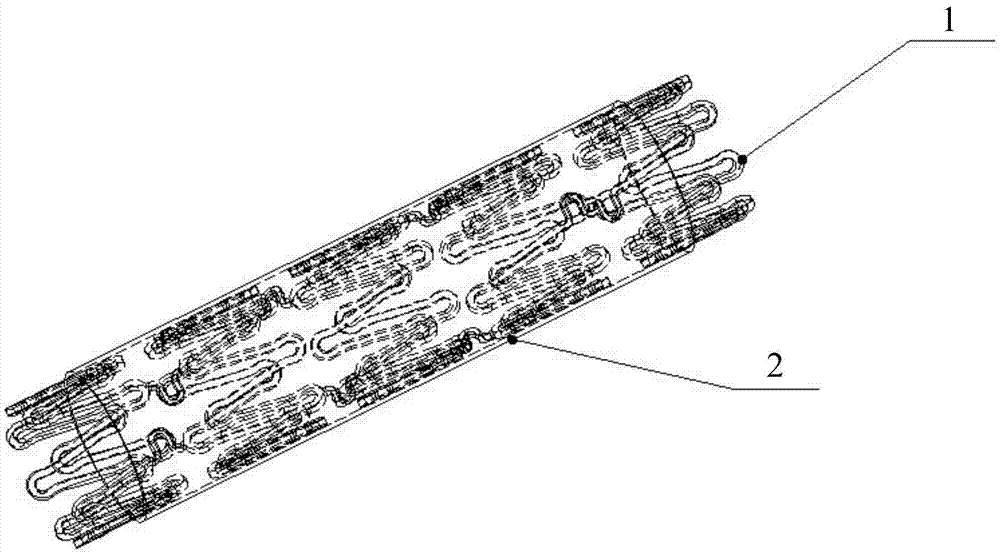

[0060] figure 1 Shown is the front view of the stent covered with film in the crimping state of Embodiment 1 of the present invention, figure 2 It is a side view of the covered stent in the crimping state of Embodiment 1 of the present invention.

[0061] refer to figure 1 and figure 2 , the covered stent includes a stent body 1 and a covered tubing 2 sheathed on the stent body 1 , and the covered tubing 2 is in a contracted state and is directly attached to the outer surface of the stent body 1 . In this way, a layer of coating material can be coated on the outer layer of the stent body 1 without additional sewing, weaving and other processes, so that the coating material can be closely attached to the surface of the stent body 1, thus a specification of the coating The membrane tubing 2 can be applied to the stent body 1 of various diameters and specifications, which improves the applicability of the stent graft and simplifies the preparation process. Moreover, the pre...

Embodiment 2

[0082] The difference between this embodiment and Embodiment 1 is that the size and shape of the film-coated pipe 3 in this embodiment have been adjusted. Specifically, when the stent body 1 is in the crimped state, the inner diameter of the coated tubing 3 is larger than the outer diameter of the stent body 1 in the crimped state, but the coated tubing 3 is sleeved on the stent body 1 It has also been folded or crimped before to form a folded film-coated pipe 3 . For the rest, this embodiment is the same as the first embodiment, and details can be referred to the first embodiment.

[0083] In this embodiment, the wall thickness of the film-coated pipe 3 before being folded or crimped is preferably less than or equal to 100 μm. For example, before preparation, select a stent body 1 with a diameter specification of 1.0 mm (that is, the outer diameter in the crimped state) and a length of 28 mm, and select a film-coated pipe 3 with an inner diameter of 3.0 mm, an outer diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com