Method for producing permanent ferrite magnet with less shrinkage

A permanent magnet ferrite and production method technology, applied in the direction of inductance/transformer/magnet manufacturing, inorganic material magnetism, electrical components, etc., can solve the problems of poor product performance consistency, long sintering time of pre-sintered materials, high energy consumption, etc., to achieve The effect of increasing production capacity, reducing kiln time and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

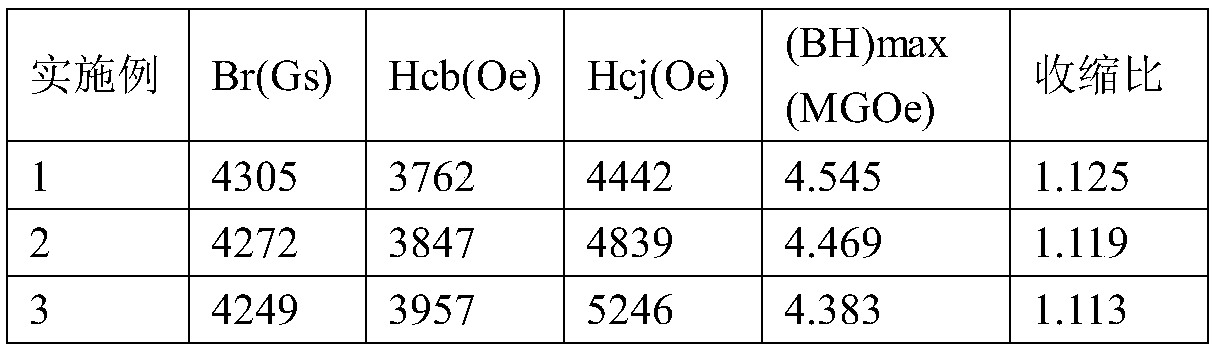

Examples

Embodiment 1

[0028] A method for producing a permanent ferrite magnet with less shrinkage, comprising the following steps:

[0029] Step 1) Add the main component into a ball mill and grind for 4 hours to obtain a slurry, wherein the main component is composed of the following components in mass percentage: 10.8% SrCO 3 , 3.4% La 2 o 3 , 1.2% Co 2 o 3 , the balance Fe 2 o 3 ;The mass percentage sum of all principal components is 100%;

[0030] Step 2) Stir the slurry in step 1) by wet method first, and then perform a mixed grinding, and then dehydrate the obtained slurry through a filter press to control the water content of the slurry to 35%;

[0031] Step 3) Putting the material in step 2) into a rotary kiln for pre-sintering, and performing a solid-state reaction at a temperature of 1250° C. to form a permanent magnet ferrite pre-sintered material;

[0032] Step 4) After the permanent magnet ferrite calcined material in step 3) is ball-milled into a coarse powder, the coarse powd...

Embodiment 2

[0035] A method for producing a permanent ferrite magnet with less shrinkage, comprising the following steps:

[0036] Step 1) Add the main component into a ball mill and grind for 5 hours to obtain a slurry, wherein the main component is composed of the following components in mass percentage: 11.0% SrCO 3 , 3.7% La 2 o 3 , 1.4% Co 2 o 3 , the balance Fe 2 o 3 ;The mass percentage sum of all principal components is 100%;

[0037]Step 2) Stir the slurry in step 1) by wet method first, then perform a mixed grinding, and then dehydrate the obtained slurry through a filter press to control the water content of the slurry to 38%;

[0038] Step 3) Putting the material in step 2) into a rotary kiln for pre-sintering, and performing a solid-state reaction at a temperature of 1250° C. to form a permanent magnet ferrite pre-sintered material;

[0039] Step 4) After the permanent magnet ferrite calcined material in step 3) is ball-milled into a coarse powder, the coarse powder is...

Embodiment 3

[0042] A method for producing a permanent ferrite magnet with less shrinkage, comprising the following steps:

[0043] Step 1) Add the main component into a ball mill and grind for 5 hours to obtain a slurry, wherein the main component is composed of the following components in mass percentage: 11.0% SrCO 3 , 3.7% La 2 o 3 , 1.4% Co 2 o 3 , the balance Fe 2 o 3 ;The mass percentage sum of all principal components is 100%;

[0044] Step 2) Stir the slurry in step 1) by wet method first, then perform a mixed grinding, and then dehydrate the obtained slurry through a filter press to control the water content of the slurry to 38%;

[0045] Step 3) Putting the material in step 2) into a rotary kiln for pre-sintering, and performing a solid-state reaction at a temperature of 1250° C. to form a permanent magnet ferrite pre-sintered material;

[0046] Step 4) After the permanent magnet ferrite calcined material in step 3) is ball-milled into a coarse powder, the coarse powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com