PVC stone-plastic floor and production method thereof

A technology of stone-plastic floor and manufacturing method, which is applied in the floor field, can solve the problems of loss of elasticity, single surface embossment, unsatisfactory shrinkage performance, etc., achieve superior foot feeling, maintain embossing fidelity, and maintain three-dimensional effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

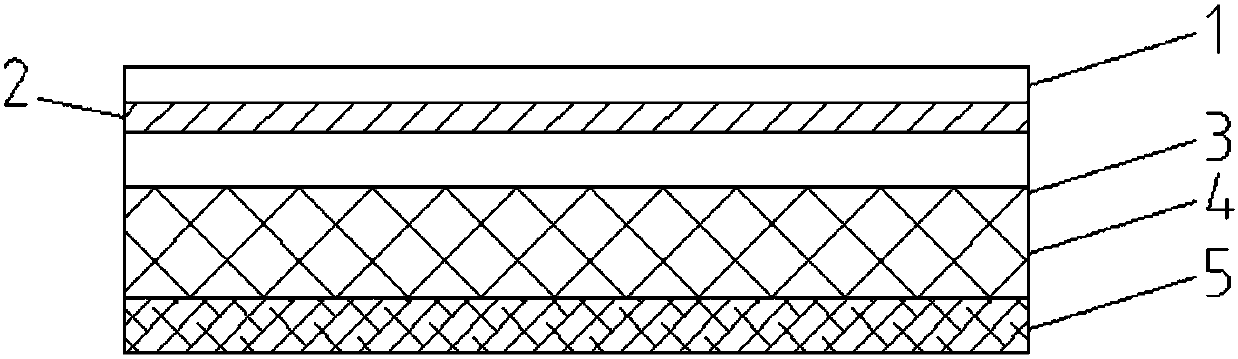

[0050] A PVC stone plastic floor, the structure is as figure 1 As shown, the PVC stone-plastic floor is formed by hot-pressing the wear-resistant layer 1, the decorative layer 3 and the base layer, and the base layer is formed by hot-pressing the middle layer 3, the stone-plastic substrate layer 4 and the bottom layer 5. The middle layer is adjacent to the decorative layer, the stone-plastic substrate layer is in the middle, and the bottom layer is at the bottom of the entire PVC stone-plastic floor.

[0051] The middle layer is mainly made of PVC resin and calcium carbonate, and the specific formula is shown in Table 1.

[0052] Table 1

[0053] Material

Dosage / kg

PVC resin

16.53

10.41

87.61

stabilizer

0.33

0.10

[0054] The stone-plastic substrate layer is mainly made of PVC resin and heavy calcium carbonate, and the specific formula is shown in Table 2. ...

Embodiment 2

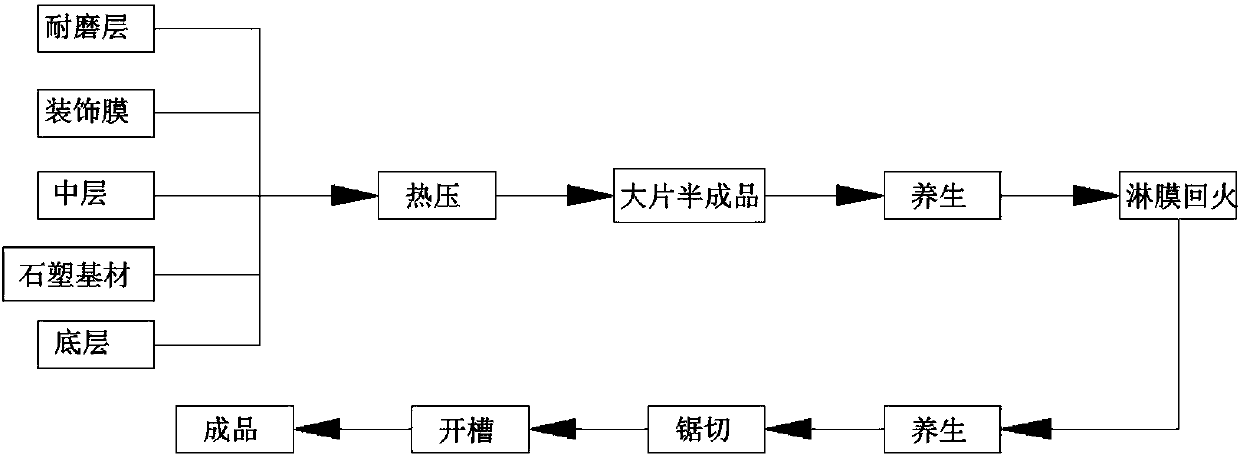

[0078] A kind of manufacture method of PVC stone-plastic floor, concrete steps are as follows:

[0079] 1. The preparation method of the middle layer and the bottom layer is as follows:

[0080] (1) The raw materials are automatically fed according to the ratio through the automatic metering system,

[0081] (2) After passing through a high-speed mixer, the stirring speed is 1200 rpm for 3 minutes, and the temperature of the material is controlled within the range of 90-110°C.

[0082] (3) Banbury internal mixing, time 3 minutes; Unloading, one roll and two rolls of the open mill, the temperature of the rolls is 160-180°C, wherein, the temperature of the first roll is 180°C, the temperature of the second roll is 175°C, and the temperature of the discharge roll 160°C.

[0083] (4) Roll out sheet by four-roll calendering, roll temperature is 150-170°C; cooling and forming, cutting according to required size to obtain middle layer and bottom layer.

[0084] The middle layer fo...

Embodiment 3

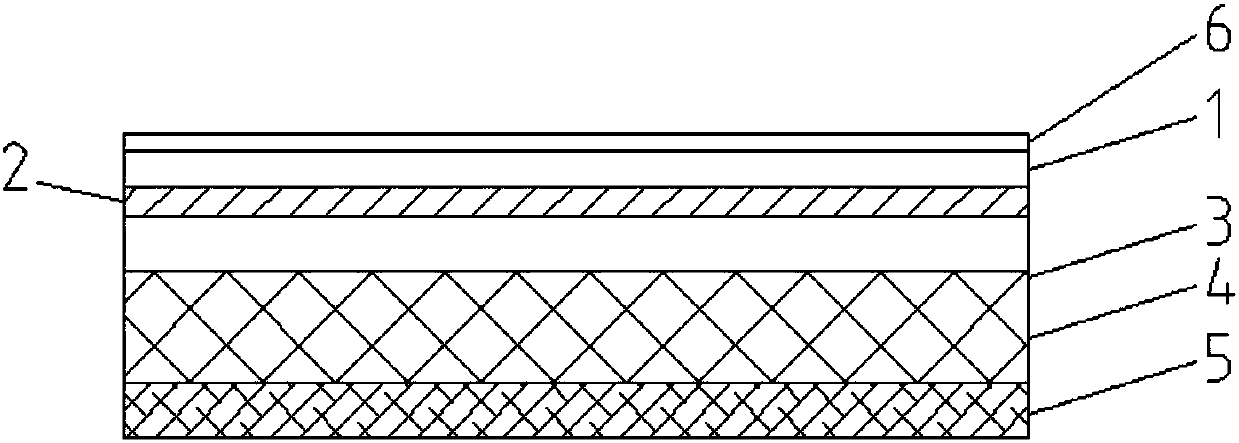

[0107] A PVC stone plastic floor, the structure is as image 3 As shown, the PVC stone-plastic floor is formed by hot-pressing the wear-resistant layer 1, the decorative layer 3 and the base layer, and the base layer is formed by hot-pressing the middle layer 3, the stone-plastic substrate layer 4 and the bottom layer 5. The middle layer is adjacent to the decorative layer, the stone-plastic substrate layer is in the middle, and the bottom layer is at the bottom of the entire PVC stone-plastic floor. The surface of the wear-resistant layer is provided with an ultraviolet light curing coating layer 6 . The UV-curable coating layer can improve the glossiness of the floor surface, enhance the wear resistance, scratch resistance, mildew resistance, stain resistance, antibacterial and other properties of the floor surface. The main component of the decorative layer is PVC resin, and patterns or patterns are printed on the surface of the decorative layer.

[0108] The total thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com