Method for preparing women's shoes capable of keeping three-dimensional for long time by utilizing natural leather

A technology for natural leather and leather shoes, applied in the field of leather, can solve problems such as insufficient tensile strength of adhesives, short durability of leather uppers, and deformation of shoe upper fillers, etc., to achieve the best bonding effect, firm bonding, and reduce with concave effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

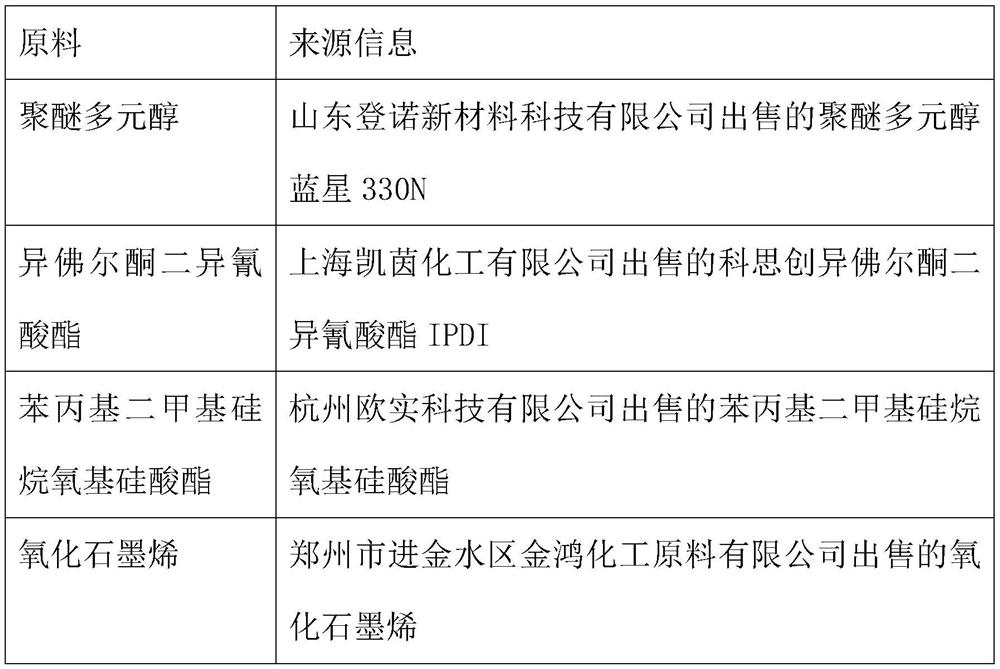

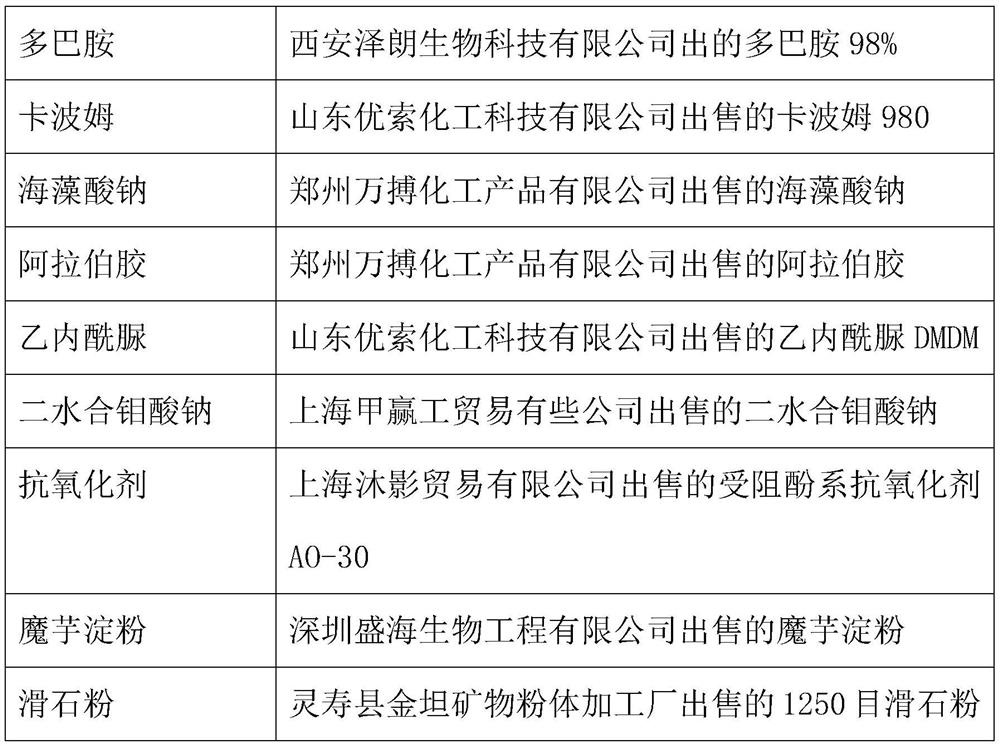

[0075] An adhesive comprising the following components:

[0076] Polyether Polyol, Isophorone Diisocyanate, Phenylpropyldimethylsiloxysilicate, Graphene Oxide, Dopamine, Thickener, Water.

[0077] The thickener is a compound of carbomer, sodium alginate and gum arabic.

[0078] In embodiment 1-3, the input amount (unit Kg) of each component sees table 2 for details

[0079] Table 2

[0080]

[0081]

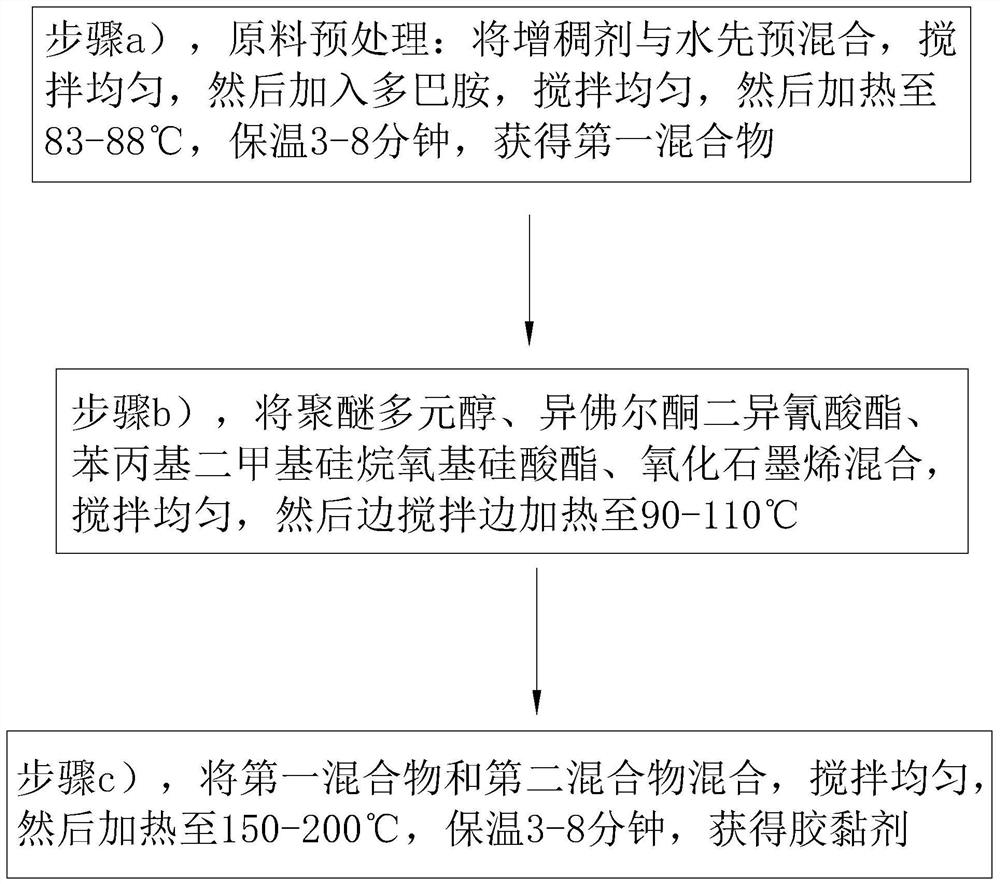

[0082] refer to figure 1 , the preparation method of adhesive in embodiment 1-3 comprises the following steps:

[0083] Step a), raw material pretreatment: first add the thickener and water into the blender and mix at a speed of 60r / min, stir evenly, then add dopamine, stir evenly, then heat to 85°C, keep warm for 5 minutes, discharge into the container, and obtain the first mixture;

[0084] Step b), adding polyether polyol, isophorone diisocyanate, phenylpropyl dimethylsiloxysilicate, and graphene oxide into the extruder, stirring evenly, and then heating to 100 °C,...

Embodiment 4

[0087] A kind of adhesive, compared with embodiment 2, difference only lies in:

[0088] In the preparation method of adhesive:

[0089] In step a), heat to 83°C and keep warm for 3 minutes;

[0090] In step b), heating to 90°C while stirring;

[0091] In step c), heat to 150° C. and keep warm for 3 minutes.

Embodiment 5

[0093] A kind of adhesive, compared with embodiment 2, difference only lies in:

[0094] In the preparation method of adhesive:

[0095] In step a), heat to 88°C and keep warm for 9 minutes;

[0096] In step b), heating to 110°C while stirring;

[0097] In step c), heat to 200° C. and keep the temperature for 8 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com