Color fiber alkali decremental waste water treating and recovering process

A technology of alkali reduction and fiber alkali, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of not removing organic and inorganic ions, recovering the purity of terephthalic acid low, the difficulty of recycling and other issues, to achieve good economic and environmental benefits, control pollution, improve the effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

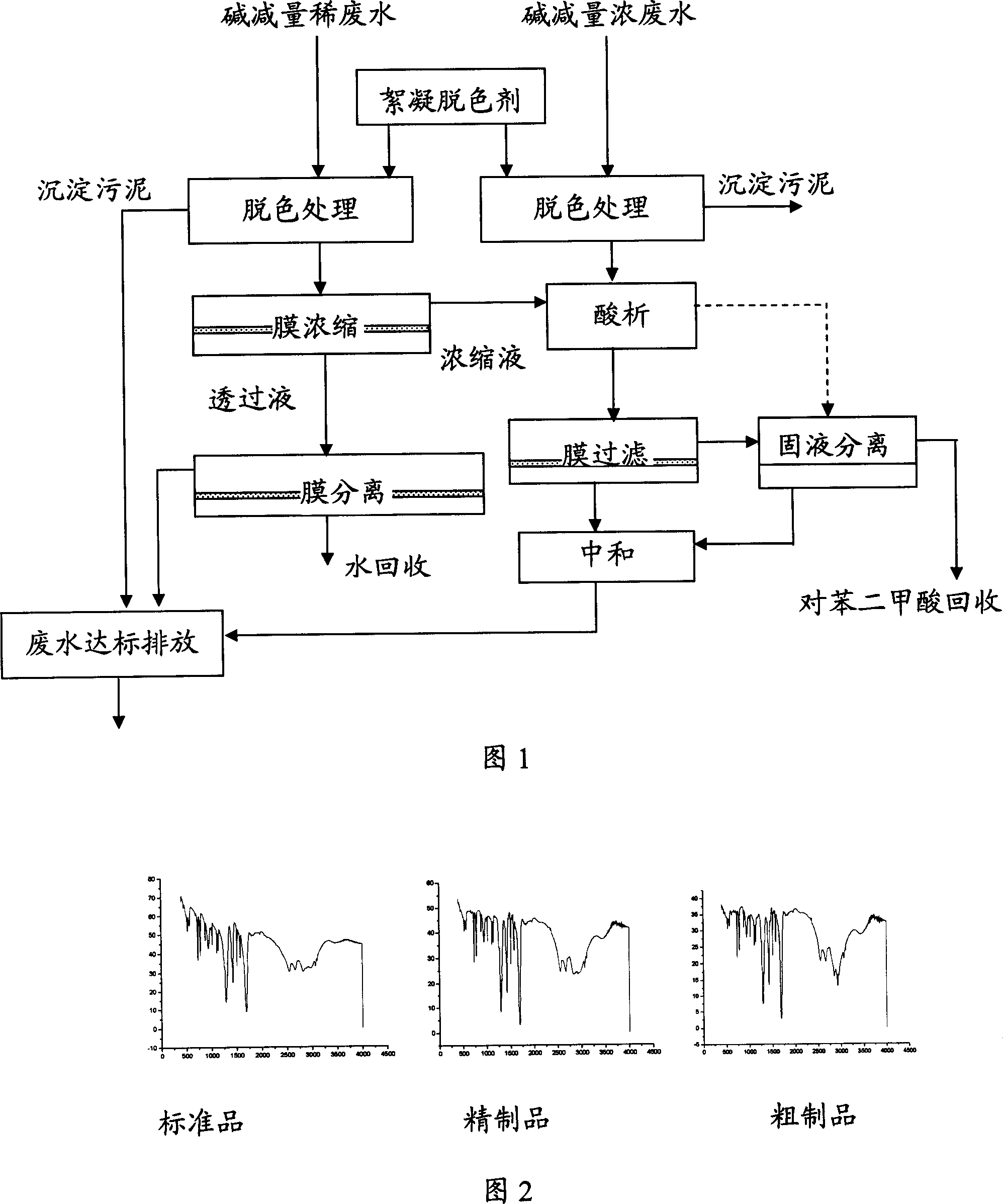

[0030] Add 20 times diluted polyacrylamide derivative flocculation and decolorization agent to the alkali reduction concentrated wastewater with a concentration of terephthalic acid greater than 0.5g / L. The amount of flocculant added is 3ml / L wastewater, stir evenly, stand still, and filter Remove chroma, particles (fibers) and colloidal substances in wastewater.

[0031] Add polyacrylamide derivative flocculation and decolorization agent diluted 20 times to the alkali reduction dilute wastewater with terephthalic acid concentration lower than 0.5g / L, the amount of flocculant added is 3ml / L wastewater, stir evenly, let stand, Filter to remove chroma, particles (fibers) and colloidal substances in wastewater. The dilute wastewater after decolorization is treated with integrated membrane filtration and concentration treatment with nanofiltration flat membrane. After membrane filtration and concentration, concentrate and permeate are obtained. The permeate is separated and treate...

Embodiment 2

[0034] Use the polyacrylamide derivative flocculation decolorant to study the influence of usage amount on the water quality of alkali reduction wastewater (6 minutes), the effect is shown in Table 1: with the increase of polyacrylamide derivative flocculation decolorant dosage, the chromaticity and a gradual decrease in turbidity. And when the amount of flocculating decolorizing agent reaches a certain value, the change of the two is no longer obvious. Considering the treatment cost, the selected dosage is 3.429ml / L waste water. In addition, the content of terephthalic acid (TA) in wastewater is hardly affected by organic polymer flocculation decolorizers.

[0035] Table 1 Selection of the amount of flocculation decolorizer

[0036] Amount of flocculation decolorizer

(ml / L waste water)

Chroma (times)

Turbidity (degrees)

TA concentration

(mg / mL)

1.714

2.057

2.400

10.0

7.0

3.0

12...

Embodiment 3

[0043] Select the following three organic polymer decolorizers respectively:

[0044] 1# Polyacrylamide Derivatives

[0045] 2# Dicyandiamide series cationic polymer compound

[0046] 3# Quaternary ammonium cationic polymer compound

[0047] Through the experiments in Table 2, 3 different organic polymer flocculation decolorizers were compared for wastewater pretreatment. The actual dosage of the 3 kinds was controlled according to the treatment cost (about 1.2 yuan / ton). From the results, it can be seen that the flocculation of 3# The decolorization effect is 1.7, 2.1 times (turbidity) and 1.4, 1.5 times (chroma) of 1# and 2# respectively, and it has less influence on TA. Therefore, it is more reasonable to choose 3# quaternary ammonium cationic polymer compound as decolorizing agent.

[0048] Table 2 Selection comparison of decolorizing agent

[0049]

Types of decolorizers

Chroma (times)

Turbidity (degrees)

TA co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com