A method for treating high-acid heavy crude oil processing wastewater

A technology for heavy crude oil and wastewater processing, applied in chemical instruments and methods, oxidized water/sewage treatment, chemical/physical processes, etc., can solve the problems of short catalyst life, poor catalytic performance, and poor catalytic efficiency, etc. Achieve the effect of stable physical and chemical properties and reduce CODcr value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of an ozone catalytic oxidation catalyst, the method comprising:

[0030] (1) Contacting the impregnation solution A containing the auxiliary elements with the carrier to obtain the carrier containing the auxiliary elements;

[0031] (2) The carrier containing the additive element is contacted with the impregnation solution B containing the active component element,

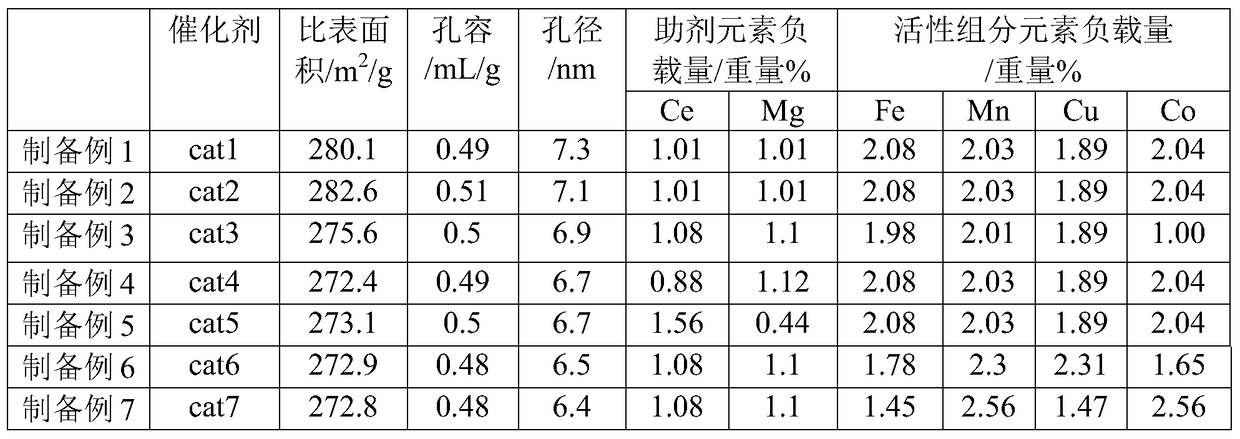

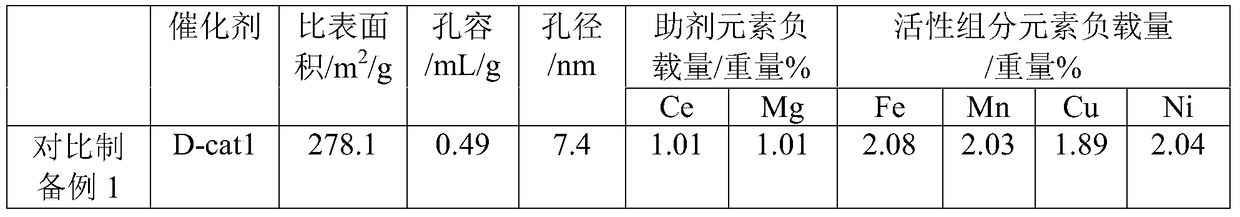

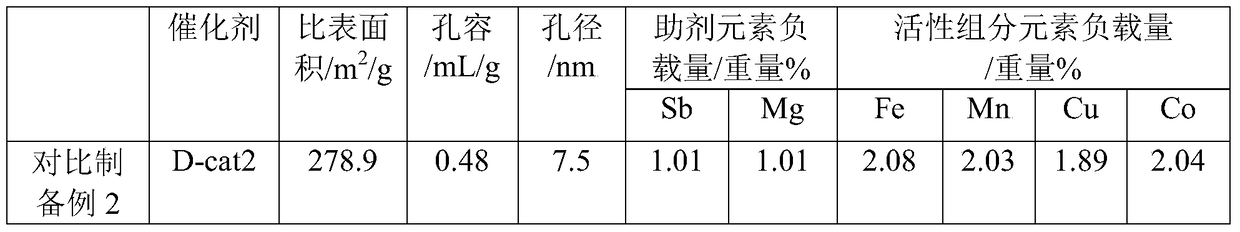

[0032] Wherein, the carrier includes γ-alumina, the active component elements include Fe, Mn, Cu and Co, and the additive elements include Ce and Mg.

[0033] In the present invention, in step (1) and / or step (2), there are multiple ways of contacting, preferably, the way of contacting is dipping. In the present invention, there may be various ways of impregnation, for example, in the present invention, an equal-volume impregnation method may be used for impregnation. In the present invention, the temperature and time of the impregnation are not particularly limited, those skilled in t...

preparation example 1

[0058] This preparation example is used to prepare the ozone catalytic oxidation catalyst of the present invention, and this preparation example adopts the following method to prepare the described catalyst:

[0059] (1) The impregnating solution A is contacted with 25kg of gamma-alumina carriers by an equal volume impregnation method to obtain a carrier containing additive elements;

[0060] (2) performing the first drying and the first calcination on the carrier containing the additive elements in sequence, wherein the temperature of the first drying is 110°C, the time of the first drying is 20min, and the temperature of the first calcination is 550°C, The time of the first roasting is 50min;

[0061] (3) Contact the carrier containing additive elements after the first calcination with the impregnation solution B by using an equal-volume impregnation method, and carry out the second drying and the second calcination sequentially on the catalyst obtained after the contact, wh...

preparation example 2

[0063] This preparation example is used to prepare the ozone catalytic oxidation catalyst of the present invention, and this preparation example adopts the following method to prepare the described catalyst:

[0064] The impregnating solution A and the impregnating solution B were contacted with 25kg of gamma-alumina carrier by the equal volume impregnation method, and the catalyst obtained after the contact was dried and calcined in sequence, wherein the drying temperature was 110°C, and the drying time was 30min. The calcination temperature was 550° C., and the calcination time was 80 minutes. After calcination, the catalyst cat2 was obtained. The physicochemical properties, active component elements and auxiliary element loadings of the catalyst cat2 are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com