Dioctyl phthalate production line and DOTP production method

A technology of dioctyl phthalate and production line, which is applied in the field of dioctyl phthalate production line and DOTP production, can solve the problems of large amount of catalyst, slightly yellow color and high content of octanol, and achieves small amount of catalyst and improved quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

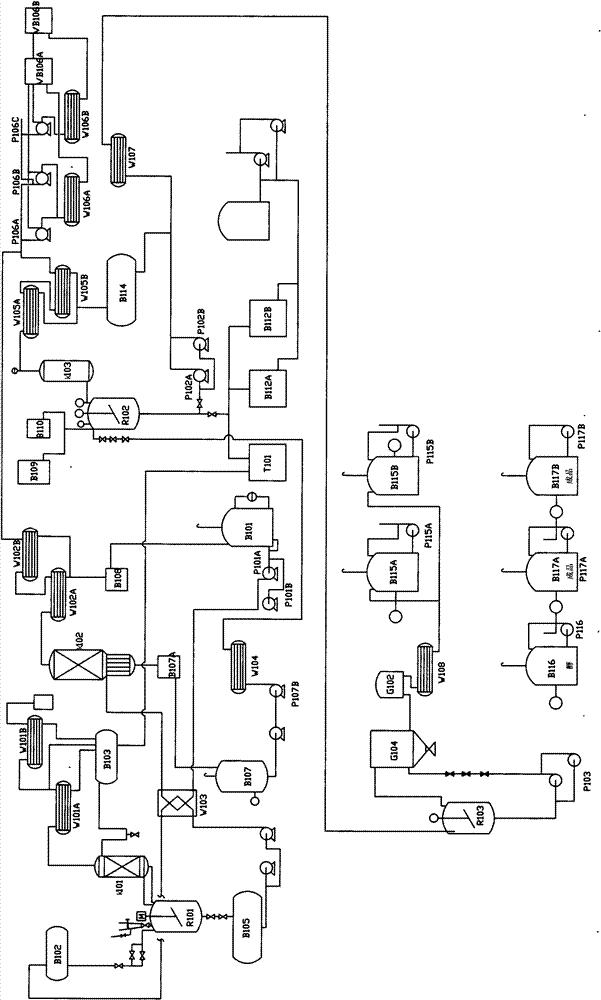

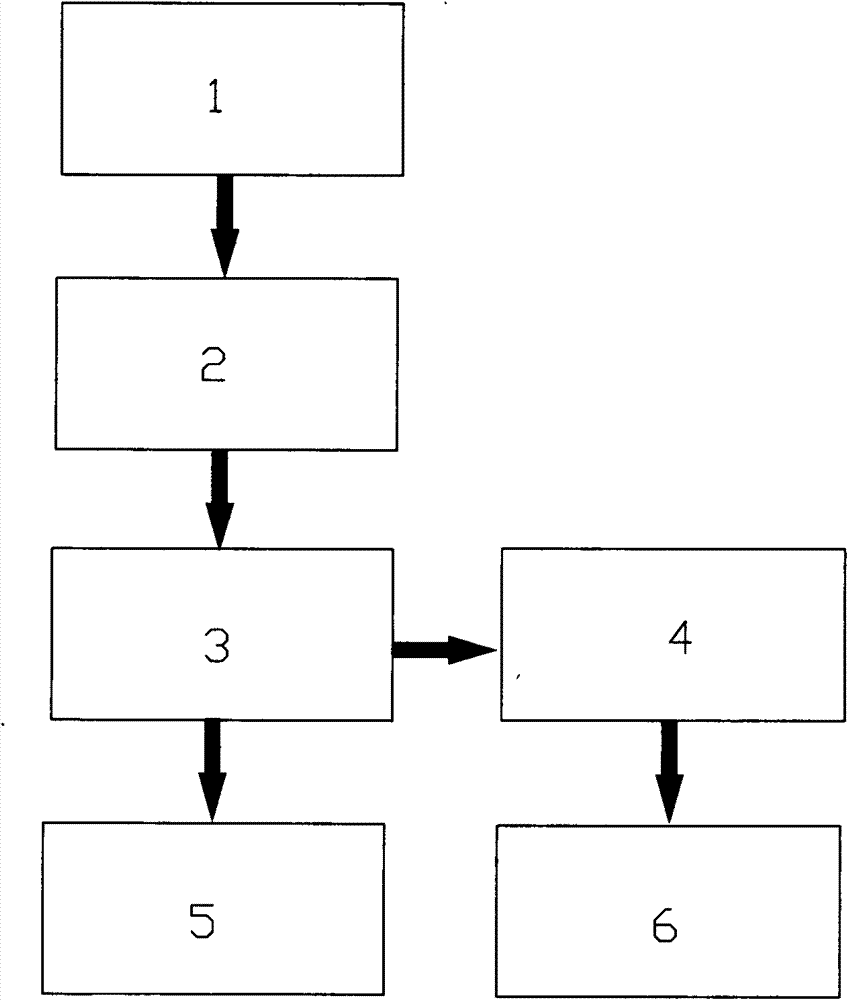

[0030] Implementation mode one: if figure 1 As shown, the dioctyl phthalate production line includes an esterification system, a dealcoholization system, a neutralization / washing system, a stripping system, a filtration decolorization system and a sewage purification recovery system, and is characterized in that:

[0031](1) The esterification system includes alcohol feed tank B102, esterification reaction kettle R101, packed tower K101, esterification system condensers W101A, W101B and esterification system condensation tank B103, wherein the bottom of alcohol feed tank B102 is provided with a feed There is a valve on the feed pipe, and it leads into the esterification reactor R101. The bottom of the esterification reactor R101 is equipped with a discharge pipe with a valve; the top of the esterification reactor R101 is equipped with an outlet pipe and an inlet with a valve. The material funnel and the gas outlet pipe go through the packing tower K101, the shell side of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com