Preparation method of environmentally-friendly disposable polyvinyl chloride glove

A polyvinyl chloride, disposable technology, used in gloves, clothing, applications, etc., can solve problems such as phthalate toxicity, and achieve the effects of low volatility, good compatibility, and low migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Use PVC paste resin as raw material and acetylated tributyl citrate (ATBC) as plasticizer. The formula ratio is shown in Table 1.

[0023] Table 1 Preparation ratio of slurry (ATBC is plasticizer)

[0024] raw material name Proportion / % Actual dosage / g PVC paste resin 100 4600 ATBC 80 3680 Calcium zinc stabilizer 0.75 34.5 Viscosity reducer (D25 dearomatization solvent) 25 1150

[0025] 2. Prepare the slurry according to the above ratio and stir for 2 hours;

[0026] 3. Check the viscosity of the slurry;

[0027] Table 2 Viscosity test of slurry

[0028] temperature / ℃ 35 40 45 50 55 57 60 65 70 75 Viscosity mPa·s 89 71 63 57 54 58 61 79 105 149

[0029] It can be seen from Table 2 that the optimal temperature of the slurry (the temperature of the slurry in the slurry tank) is between 55 and 57°C, and when the temperature exceeds 60°C, its viscosity rises sharply. It can be seen th...

Embodiment 2

[0035] Compound Plasticizer of ATBC and Epoxy Fatty Acid Methyl Ester

[0036] 1. Prepare the slurry according to the following ratio;

[0037] Table 4 The preparation ratio of slurry (ATBC and epoxy fatty acid methyl ester compound plasticizer)

[0038] raw material name Proportion / % Actual dosage / KG PVC paste resin 100 4600 ATBC 70 3220 epoxy fatty acid methyl ester 10 460 Calcium zinc stabilizer 0.75 34.5 Viscosity reducer 25 1150

[0039] 2. Stir the prepared slurry for 2 hours, and treat it with vacuum -0.29MPa. There are a lot of small bubbles on the surface of the slurry after standing still. After vacuum defoaming, put it in an oven and heat it to 52°C;

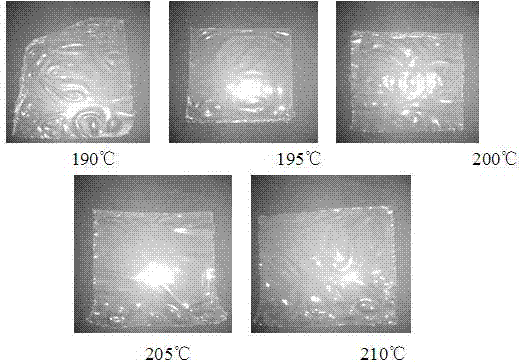

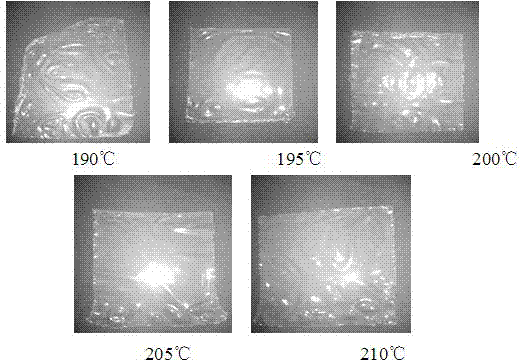

[0040] 3. After heating the tiles to 60°C, soak them in the slurry, take them out and drop them for 1 minute, then put them into ovens with temperatures of 190°C, 195°C, 200°C, 205°C, and 210°C±3°C for 10 minutes. , making the PVC mature into such figure 1 film s...

Embodiment 3

[0044] Dioctyl terephthalate / trioctyl trimellitate compounded as plasticizer

[0045] 1. Prepare the slurry according to the following ratio;

[0046] Table 5 Preparation ratio of slurry (dioctyl terephthalate plasticizer)

[0047] raw material name Proportion / % Actual dosage / KG PVC paste resin 100 4000 Dioctyl Terephthalate / Trioctyl Trimellitate 80(40 / 40) 3200(1600 / 1600) Calcium zinc stabilizer 0.75 30 Viscosity reducer 32 1280

[0048] 2. Prepare the slurry according to the above ratio and stir for 2 hours;

[0049] 3. Test the viscosity of the slurry at different temperatures;

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com