Low-volatile-separation PVC (Polyvinyl Chloride) particle composition and preparation method and application thereof

A composition and low-volatility technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of polluting the surface of products, reducing elasticity, and slowly hardening PVC products, so as to achieve low volatility and prolong service life , the effect of preventing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

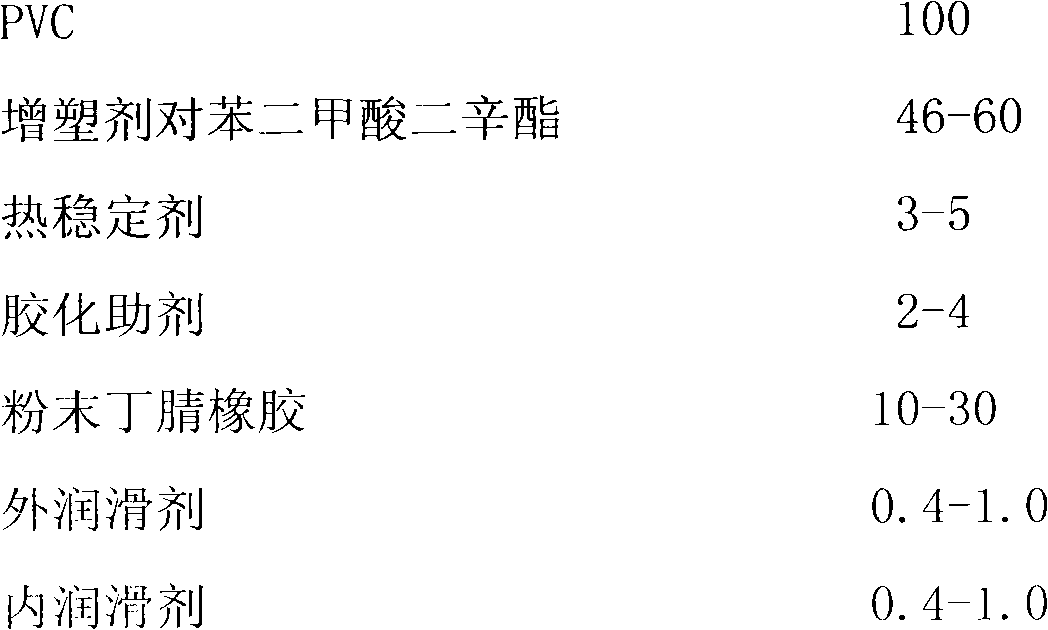

[0037] The low-volatility PVC pellet composition in the present embodiment comprises the following components, and the proportioning by weight of other components based on 100 parts by weight of PVC is as follows:

[0038]

[0039] In addition, it also includes the following components, and the weight ratio based on 100 weight parts of PVC is:

[0040]

[0041] In this embodiment, the heat stabilizer is a Ca / Zn stabilizer, the gelling aid is a methacrylate copolymer and is selected from P551 brand, the external lubricant is polyethylene wax, and the internal lubricant is stearic acid, powder Nitrile rubber selects P83 brand.

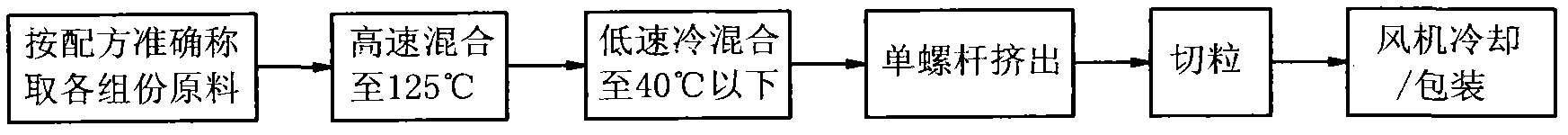

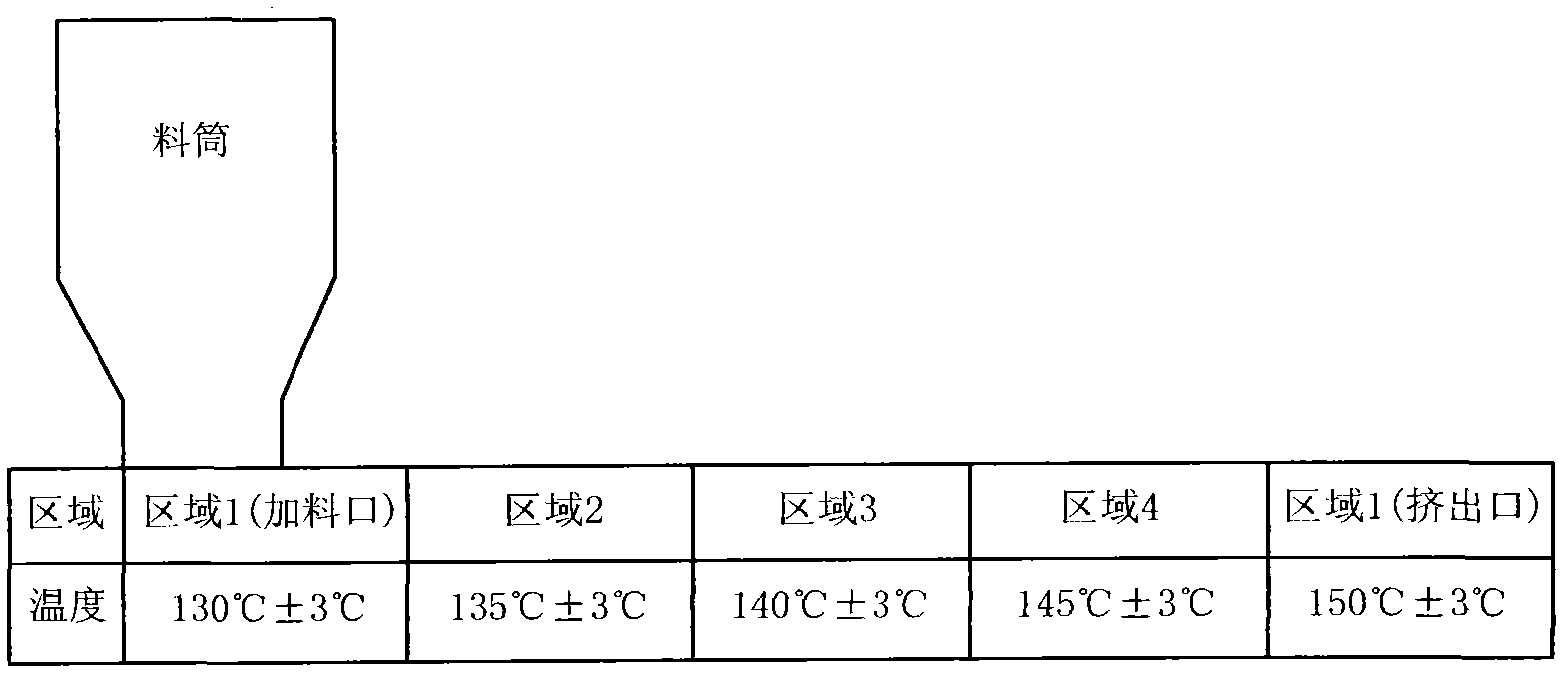

[0042] For its preparation process, see figure 1 , the specific steps are:

[0043] a. Calculate the required weight of each component according to the weight ratio, and weigh each component raw material according to the calculated result;

[0044] b. Put all the components except powdered nitrile rubber into the high-speed mixer, start the mach...

Embodiment 2

[0054] The low-volatility PVC pellet composition in the present embodiment comprises the following components, and the proportioning by weight of other components based on 100 parts by weight of PVC is as follows:

[0055]

[0056]In addition, it also includes the following components, and the weight ratio based on 100 weight parts of PVC is:

[0057]

[0058] In this embodiment, the heat stabilizer is a Ca / Zn stabilizer, the gelling aid is a methacrylate copolymer and is selected from P551 brand, the external lubricant is polyethylene wax, and the internal lubricant is stearic acid, powder Nitrile rubber selects P83 brand.

[0059] Its preparation method refers to Example 1.

[0060] After testing, its main performance indicators including high-temperature volatilization loss indicators can also meet the requirements listed in Table 1. Because the present embodiment plasticizer dioctyl terephthalate content selects minimum 46, so plasticizer dioctyl phthalate selects ...

Embodiment 3

[0063] The low-volatility PVC pellet composition in the present embodiment comprises the following components, and the proportioning by weight of other components based on 100 parts by weight of PVC is as follows:

[0064]

[0065] In addition, it also includes the following components, and the weight ratio based on 100 weight parts of PVC is:

[0066]

[0067] In this embodiment, the heat stabilizer is a Ca / Zn stabilizer, the gelling aid is a methacrylate copolymer and is selected from P551 brand, the external lubricant is polyethylene wax, and the internal lubricant is stearic acid, powder Nitrile rubber selects P83 brand.

[0068] Its preparation method refers to Example 1.

[0069] After testing, its main performance indicators including high-temperature volatilization loss indicators can also meet the requirements listed in Table 1. Since the plasticizer dioctyl terephthalate with a higher market price in this embodiment has more content, the single index of high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com