Method for preparing environment-friendly plasticizer by recycling waste resources

An environmentally friendly plasticizer and waste resource technology, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of high purity requirements, low product quality, waste of effective resources, etc., and achieve good color and luster. , Small scale of equipment investment, the effect of solving waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

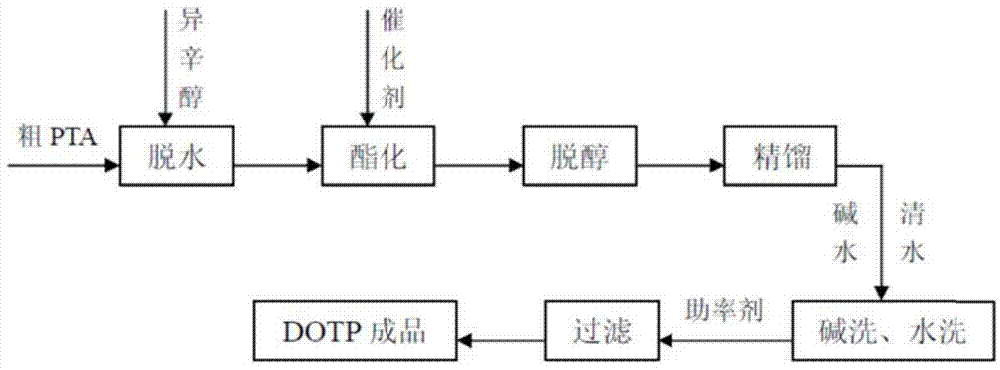

Method used

Image

Examples

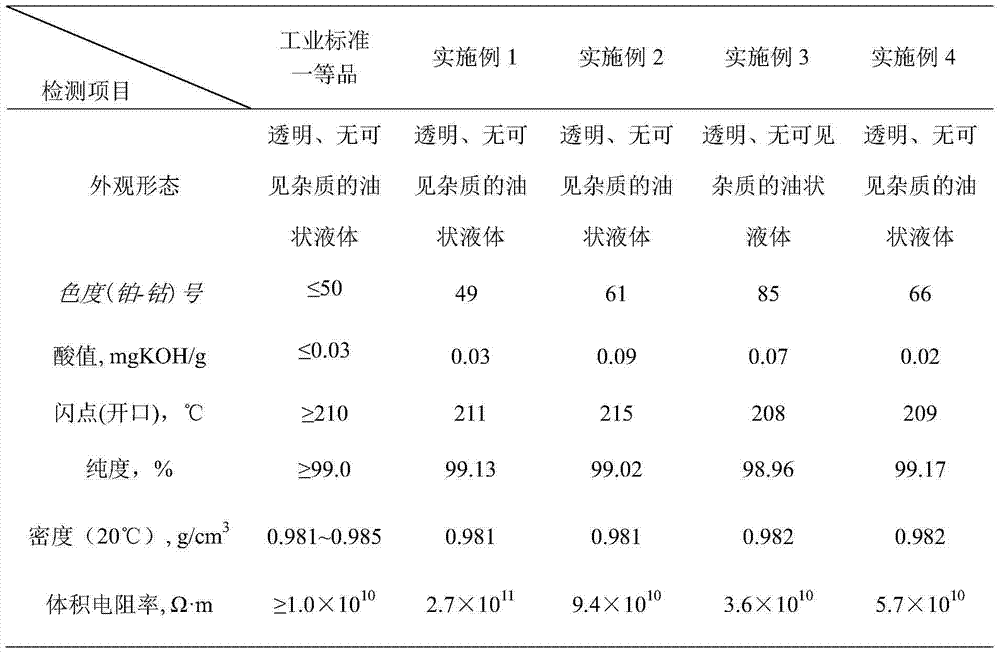

Embodiment 1

[0020] (1) PTA crude material recovery, the alkali reduction waste water (pH value is 14, PTA sodium concentration is 5000mg / L) is transferred in the acid analysis tank with stirring device, adds sulfuric acid and constantly stirs, continues to separate out PTA solid, Until the pH of the wastewater is 3-5. The mixed solution is subjected to plate-and-frame filtration, and the filter cake is recovered PTA crude material. After testing, the water content of the PTA crude material is 30 wt%, and the pH value is 4.

[0021] (2) The preparation of DOTP, the above-mentioned reclaimed PTA crude material and octanol are added in the esterification reactor with alcohol-water separation device, the mass ratio of PTA crude material and iso-octanol is 1:1.5, and mechanical stirring is started Heating and dehydration, when the reaction temperature reaches 180°C, add the catalyst tetrabutyl titanate to carry out the esterification reaction, the amount added is 0.5% of the total mass of the ...

Embodiment 2

[0024] (1) PTA crude material recovery, the alkali reduction wastewater (pH value is 14, PTA concentration is 2000mg / L) is transferred to the acid analysis tank with stirring device, sulfuric acid is added slowly and stirred continuously, and PTA solid is continuously precipitated , until the wastewater pH is 3-5. The mixed solution is subjected to plate and frame filtration, and the filter cake is recovered PTA crude material. The water content of the PTA crude material is 45 wt% and the pH value is 3 after testing.

[0025] (2) The preparation of DOTP, the above-mentioned reclaimed PTA crude material and octanol are added in the esterification reactor with alcohol-water separation device, the mass ratio of PTA crude material and isooctyl alcohol is 1:2.3, open mechanical stirring to carry out Heating and dehydration, when the reaction temperature reaches 180°C, add the catalyst tetrabutyl titanate to carry out the esterification reaction, the amount added is 0.3% of the tota...

Embodiment 3

[0028] (1) PTA coarse material recovery, the alkali reduction wastewater (pH value is 14, PTA concentration is 1300mg / L) is transferred to the acid analysis tank with stirring device, sulfuric acid is added slowly and stirred continuously, and PTA solid is continuously precipitated , until the wastewater pH is 3-5. The mixed solution is filtered with a plate and frame, and the filter cake is recovered PTA crude material. The water content of the PTA crude material is 52wt% and the pH value is 1 after testing.

[0029](2) The preparation of DOTP, the above-mentioned reclaimed PTA crude material and octanol are added in the esterification reactor with alcohol-water separation device, the mass ratio of PTA crude material and iso-octanol is 1:1.4, open mechanical stirring to carry out Heating and dehydration, when the reaction temperature reaches 180°C, add the catalyst tetrabutyl titanate to carry out the esterification reaction, the amount added is 0.7% of the total mass of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com