Polyvinyl chloride cable sheath material for CMR-grade high-flame-retardant environment-friendly coaxial cable

A polyvinyl chloride cable and coaxial cable technology, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of flame retardant effects, large attenuation, and poor transmission performance, and achieve excellent flame retardant and environmental performance, Good shell formation and durability, high sheath strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

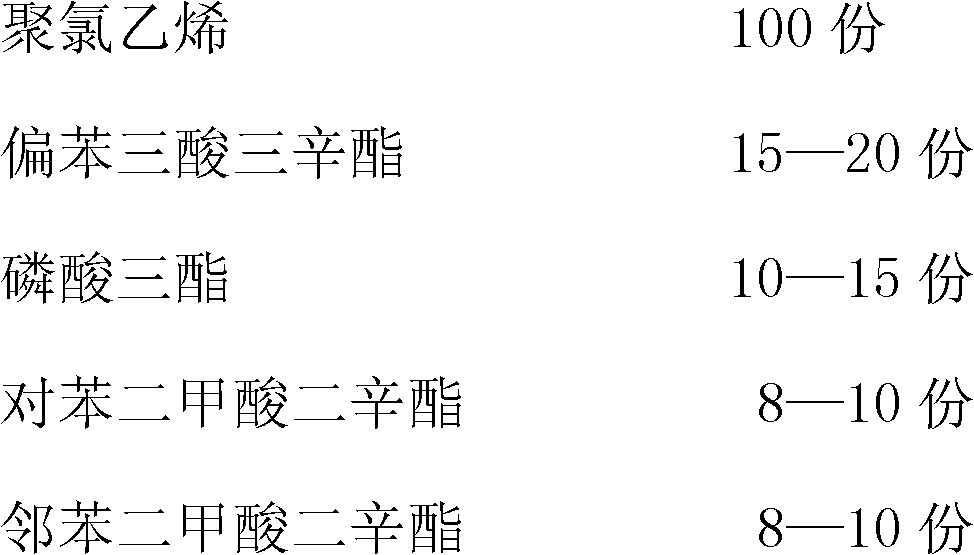

[0032] Embodiment 1: the sheath material is mainly prepared from the following materials by weight:

[0033]

Embodiment 2

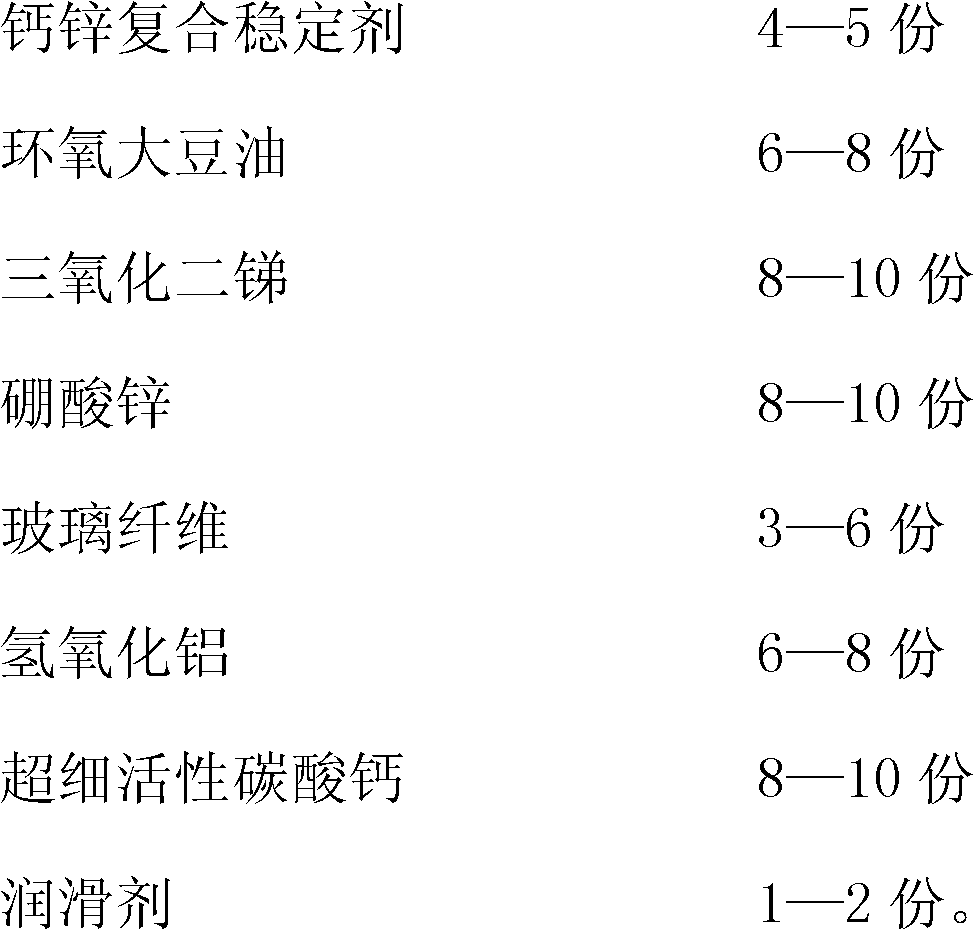

[0034] Embodiment 2: Further, the sheath material is mainly prepared from the following materials in parts by weight:

[0035]

[0036]

[0037] The production process of the above-mentioned sheath material consists of three major processes: batching, mixing and extrusion. Batching is to mix the above-mentioned raw materials according to the formula; mixing is to mix various raw materials at high speed; extrusion is to heat and plasticize the high-speed mixed raw materials to form plastic granule products. The production process is to mix the ingredients quickly, then plasticize the mixture, extrude and cut into pellets, and finally pack and leave the factory after passing the cooling test.

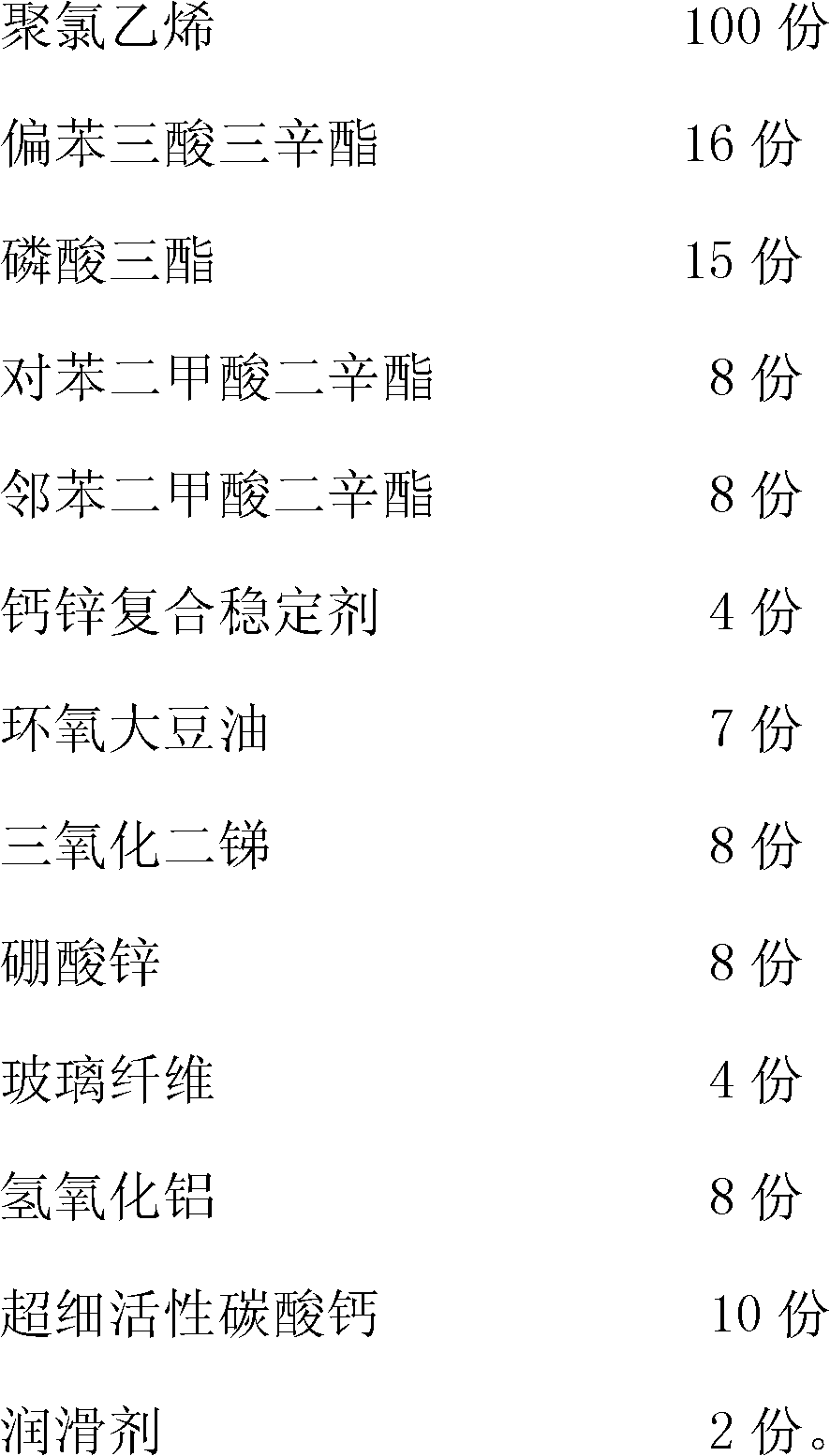

[0038] The following is a comparison table of the application effect of the flame-retardant sheath material used in the RG6 cable specification and the sheath material of the two embodiments of the present invention.

[0039]

[0040] It can be seen from the above that the stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com