High-modulus and high-elasticity asphalt additive, preparation method thereof and application thereof

An asphalt additive and high-elasticity technology, used in building components, building insulation materials, buildings, etc., can solve problems such as difficulty in melting asphalt, and achieve the effects of improved shear resistance, simple preparation and application processes, and simple components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 100 parts of polymer resin, 40 parts of filler, 20 parts of softener, 6 parts of ultraviolet light shielding agent, 1 part of accelerator, wherein the polymer resin is composed of LDPE, HDPE and PC in a mass ratio of 1:0.1:0.05, LDPE was purchased from Sinopec Qilu Petrochemical Company, the model was 2100TN00, and the melt index was 0.3g / 10min; HDPE was purchased from Sinopec Qilu Petrochemical Company, the model was DMD 6147, and the melt index was 10g / 10min; PC was Mitsubishi High Viscosity Anti-ultraviolet grade CLS400, the melt index is 5.2g / 10min; the filler is organic bentonite, from Weifang Huixin Bentonite Co., Ltd., the mesh is 300 mesh; the softener is dioctyl terephthalate, from Weifang Limin Chemical Co., Ltd. company The ultraviolet light shielding agent is carbon black, from Guangzhou Liben Rubber Raw Material Company, the model is N550, the mesh number is 600; the accelerator is zinc dibenzyl dithiocarbamate, from Chengdu Gracia Chemical Technology Co.,...

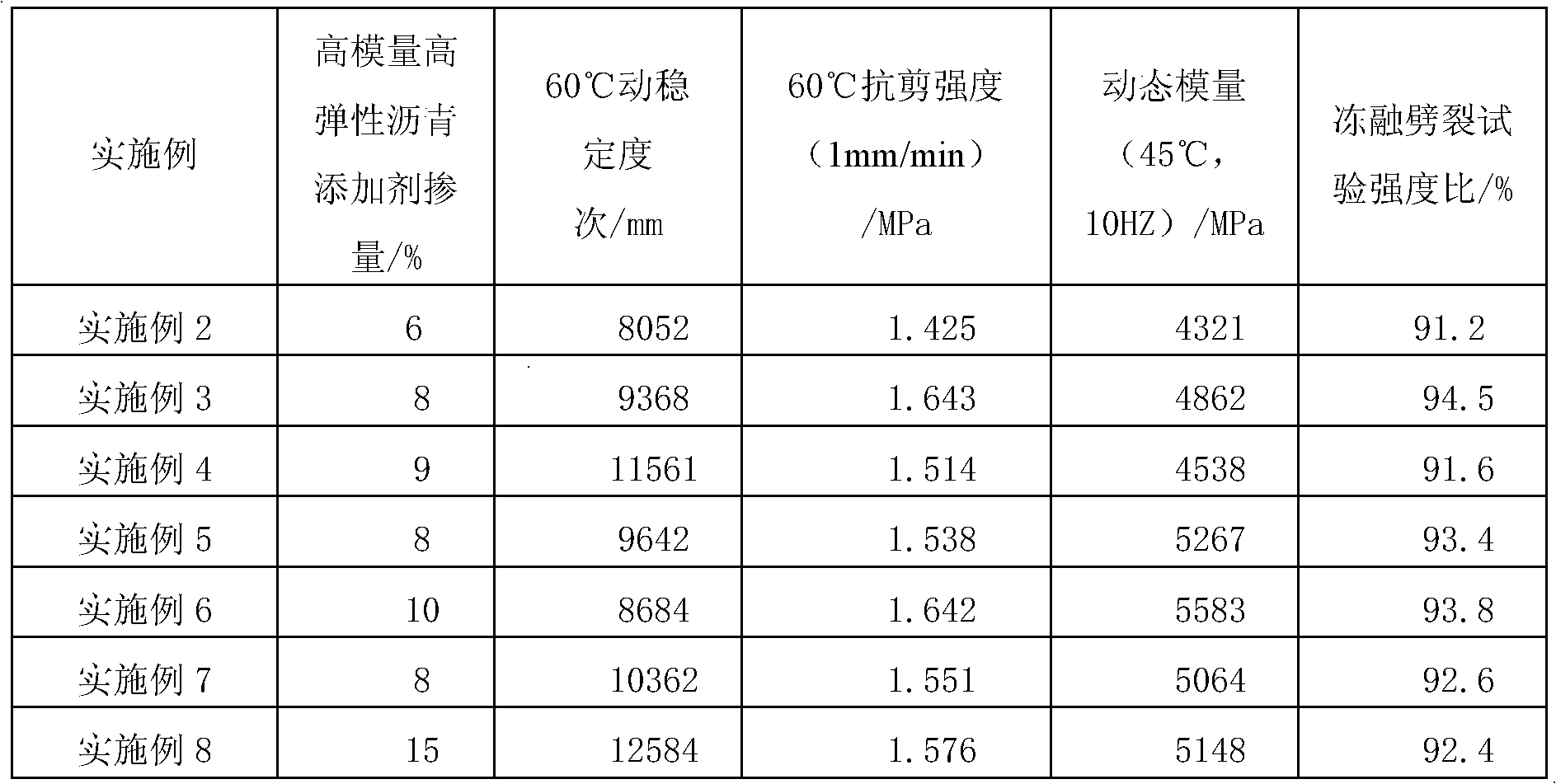

Embodiment 2

[0043] 100 parts of polymer resin, 60 parts of filler, 40 parts of softener, 12 parts of ultraviolet light shielding agent, 4 parts of accelerator, wherein the polymer resin is composed of LDPE, HDPE and PC in a mass ratio of 1:2:0.5, LDPE was purchased from Sinopec Qilu Petrochemical Company, the model is 2102TU2, and the melt index is 2.5g / 10min; HDPE is purchased from Yangzi Petrochemical BASF Co., Ltd., the model is YEM-4803T, the melt index is 8.5g / 10min; PC is the United States GE Optical grade LS1 with a melt index of 6.4g / 10min; the filler is kaolin from Kairui Mineral Products Processing Factory in Lingshou County, the mesh number is 400 mesh; the softener is dioctyl terephthalate from Weifang Limin Chemical Industry Co., Ltd.; the ultraviolet light shielding agent is carbon black, from Tianjin Lihuajin Carbon Black Co., Ltd., the model is N800, the mesh number is 1000; the accelerator is zinc dibenzyl dithiocarbamate, from Chengdu Gracia Chemical Technology Ltd.

[...

Embodiment 3

[0047] 100 parts of polymer resin, 40 parts of filler, 40 parts of softener, 6 parts of ultraviolet light shielding agent, and 1 part of accelerator, wherein the polymer resin is composed of LDPE, HDPE, and PC in a mass ratio of 1:0.1:0.5, LDPE was purchased from Yangzi Petrochemical BASF Co., Ltd., the model was 1810D, and the melt index was 0.2g / 10min; HDPE was purchased from Sinopec Qilu Petrochemical Company, the model was DGDB 2480, and the melt index was 0.1g / 10min; PC was GE Optical Grade LS1, the melt index is 6.4g / 10min; the filler is organic bentonite from Weifang Huixin Bentonite Co., Ltd., the mesh number is 300 mesh; the softener is dioctyl terephthalate, from Shandong Aokai Chemical Co., Ltd.; The light shielding agent is carbon black from Tianjin Lihuajin Carbon Black Co., Ltd., the model is N800, and the mesh number is 1000; the accelerator is zinc dibenzyl dithiocarbamate from Qingdao Lianhao Chemical Co., Ltd.

[0048] The preparation method is as follows: ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com