Hybrid driving system and vehicle

A drive system and hybrid technology, applied in hybrid vehicles, motor vehicles, power plants, etc., can solve the problems of high energy consumption, improve fuel economy, solve the power problems of high-speed engines, and solve low-speed and medium-low speed engines Effects of Efficiency Problems and Electrical Balance Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

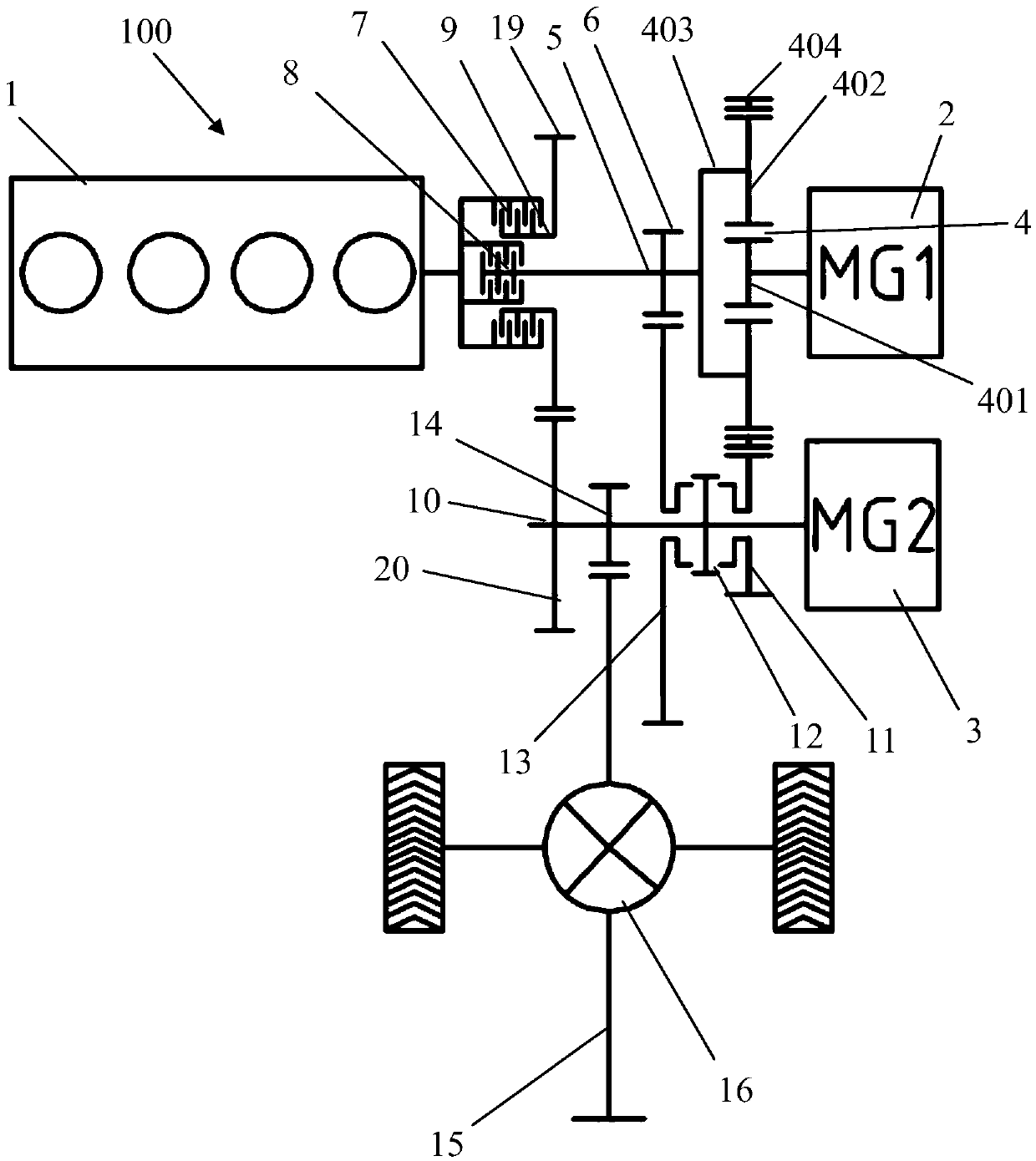

[0040] like figure 1 As shown, the hybrid drive system 100 provided by the first embodiment of the present invention includes an engine 1, a first motor 2, a second motor 3, a single-row planetary gear mechanism 4, a first shaft 5, a driving gear for first gear 6, a first First clutch 7, second clutch 8, second shaft 9, second gear driving gear 19, third shaft 10, outer ring gear driven gear 11, first synchronizer 12, first gear driven gear 13, main minus driving gear 14. 2nd gear driven gear 20 and main minus driven gear 15.

[0041] The single row planetary gear mechanism 4 includes a sun gear 401 , a planet gear 402 , a planet carrier 403 and a ring gear 404 . The planetary gear 402 is externally meshed with the sun gear 401 , and the planetary gear 402 is internally meshed with the ring gear 404 , and the planetary gear 402 is rotatably supported on the planetary gear 403 by a pin shaft arranged on the planet carrier 403 Rack 403.

[0042] The main reduction and driven ...

no. 2 example

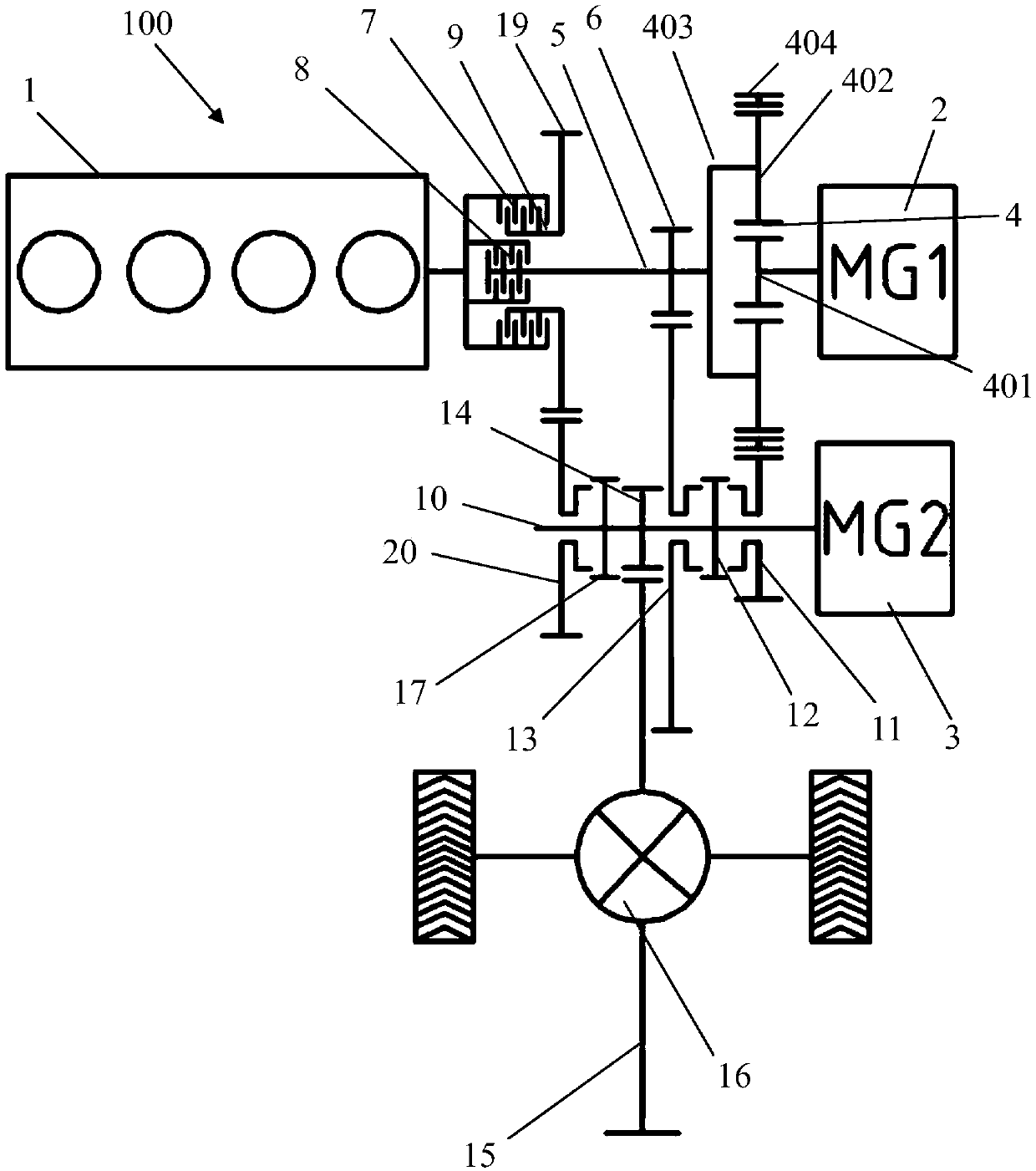

[0050] figure 2 Shown is the hybrid drive system 100 provided by the second embodiment of the present invention, which is different from the first embodiment in that the outer ring gear driven gear 11, the second speed driven gear 20 and the first speed driven gear 13 The idle sleeve is on the third shaft 10 , and the main and reduction drive gear 14 is fixedly connected to the third shaft 10 .

[0051] Another difference from the first embodiment is that the hybrid drive system 100 further includes a second synchronizer 17, and the first synchronizer 12 is arranged on the third shaft 10 and located on the external gear Between the ring driven gear 11 and the first speed driven gear 13, the first synchronizer 12 can selectively engage or disengage with the outer ring gear driven gear 11 and the first speed driven gear 13; The second synchronizer 17 is arranged on the third shaft 10 and is located between the 2nd speed driven gear 20 and the main minus driving gear 14, and th...

no. 3 example

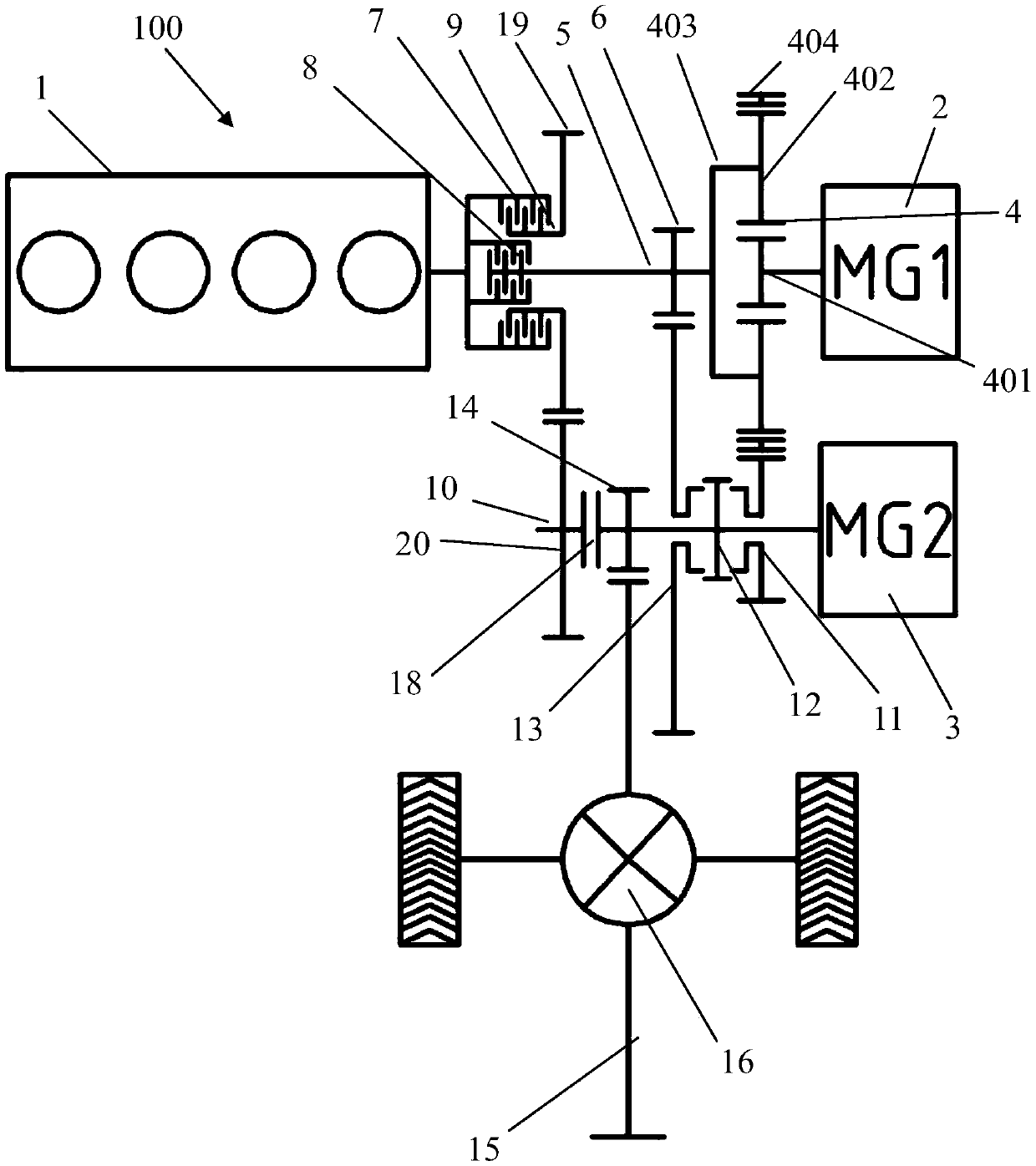

[0054] image 3 Shown is the hybrid drive system 100 provided by the third embodiment of the present invention, which differs from the first embodiment in that the hybrid drive system 100 further includes a third clutch 18, and the first synchronizer 12 is set at On the third shaft 10 and located between the outer ring gear driven gear 11 and the first speed driven gear 13, the first synchronizer 12 can be selectively connected with the outer ring gear driven gear 11 and The first speed driven gear 13 is engaged or disconnected; the third clutch 18 is arranged on the third shaft 10 and is located between the second speed driven gear 20 and the main minus driving gear 14 .

[0055] The outer ring gear driven gear 11, the first synchronizer 12, the first speed driven gear 13, the main minus driving gear 14, the third clutch 18 and the second speed driven gear 20 are aligned along the axis of the third shaft 10. Arranged sequentially in a direction close to the engine 1 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com