COS welding fixture for semiconductor laser

A technology of welding fixtures and lasers, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as COS displacement deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

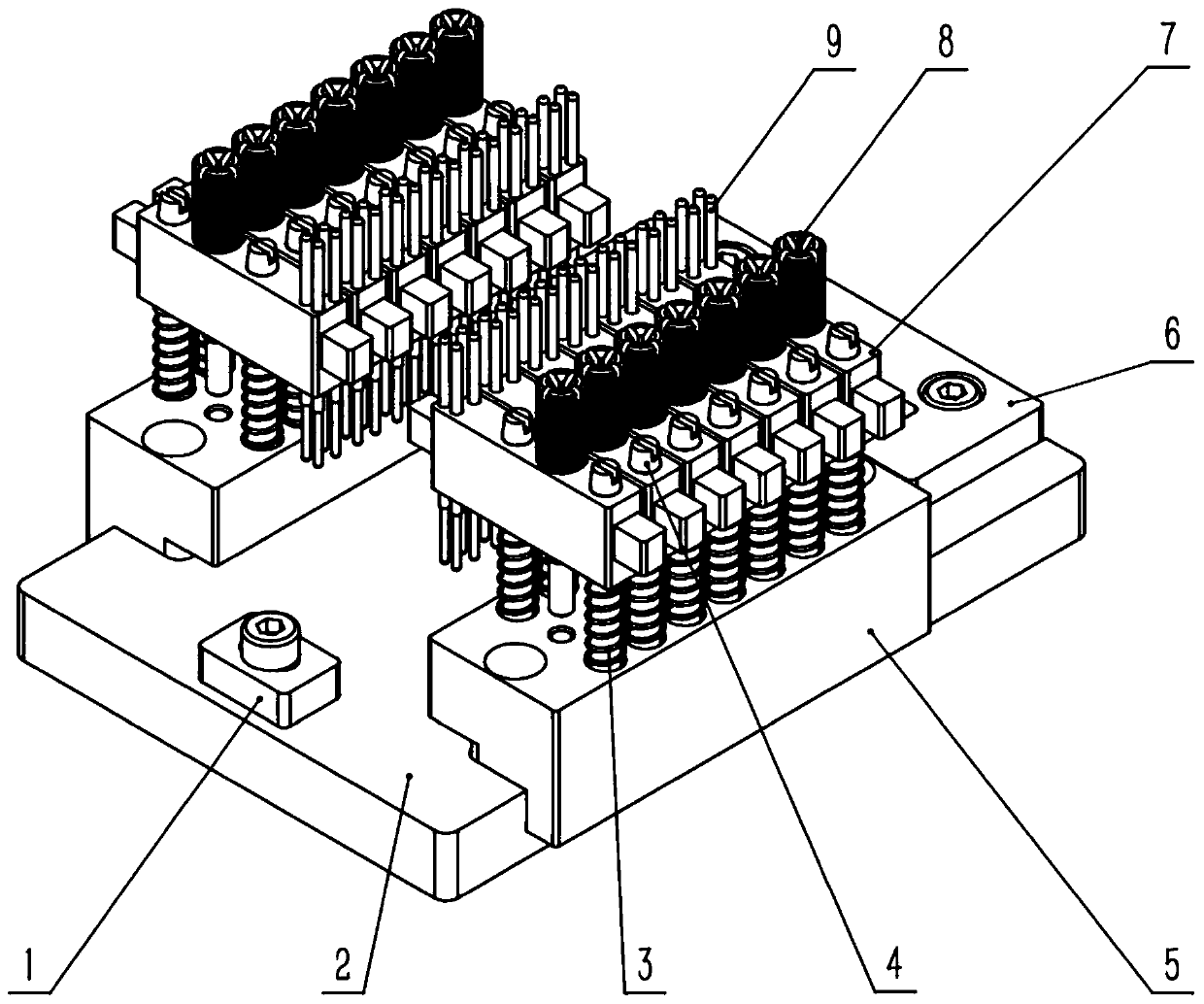

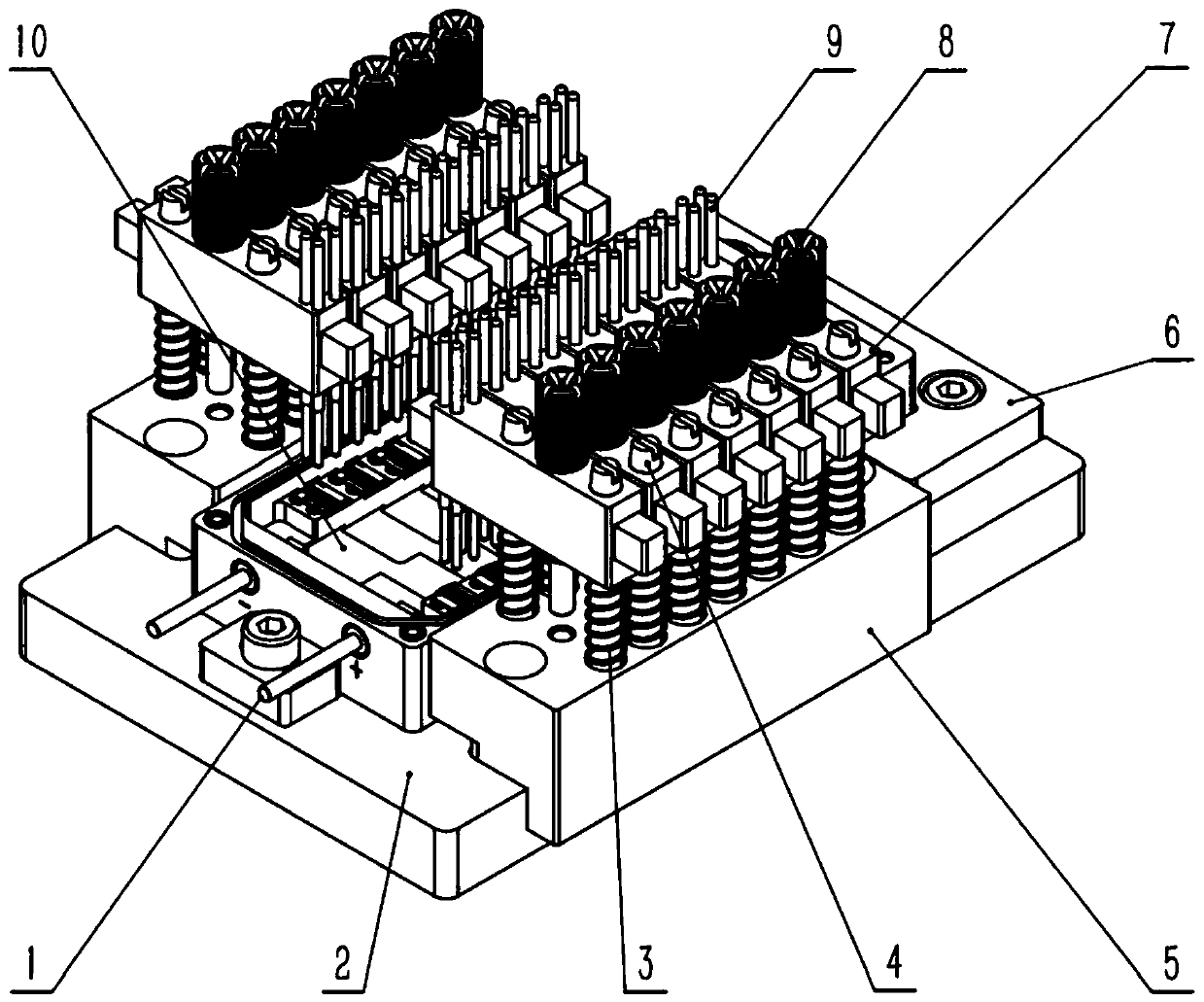

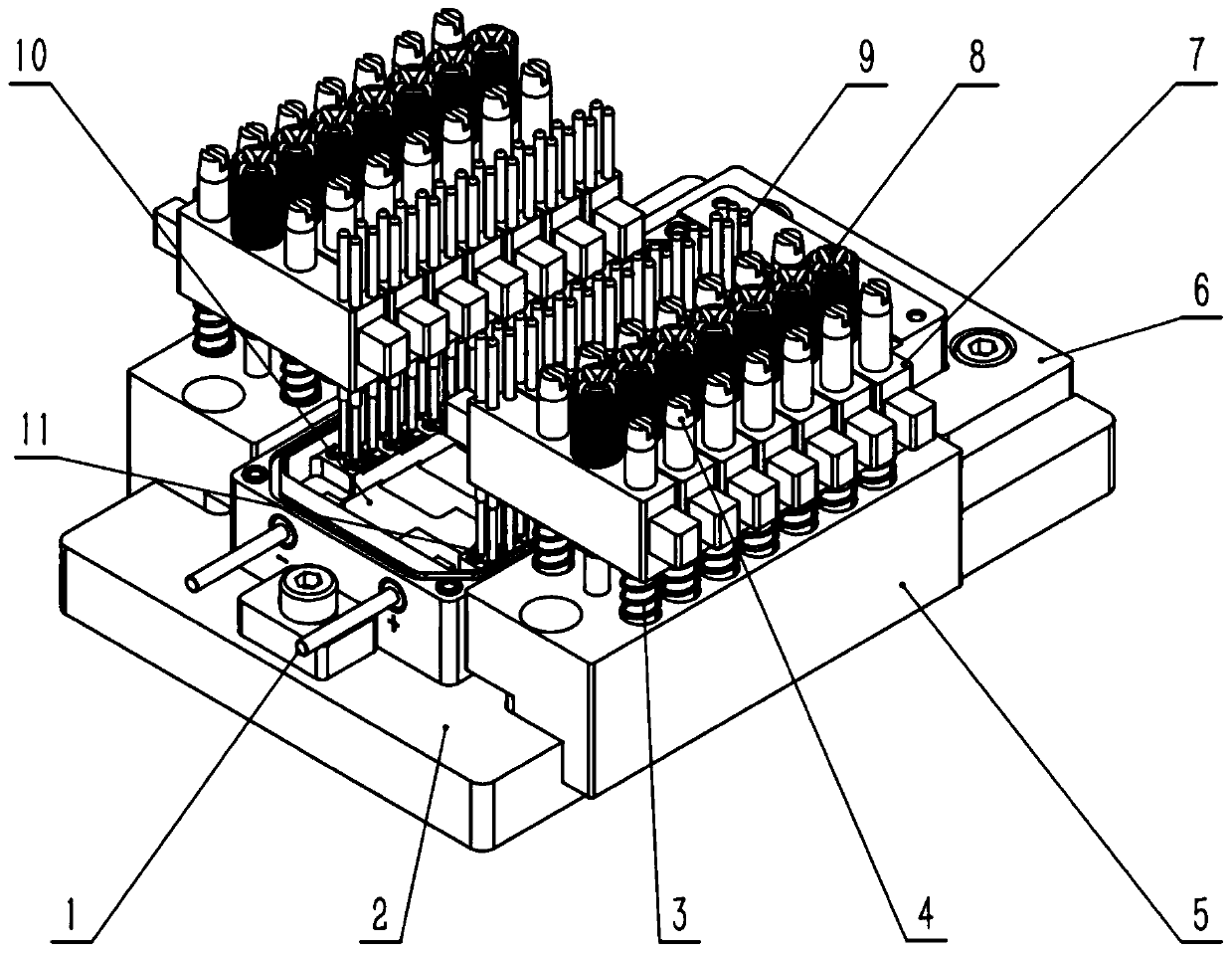

[0020] See attached Figure 1~3 . A COS welding fixture used in a semiconductor laser, comprising a bearing positioning assembly and at least one cantilever spring probe assembly; the bearing positioning assembly is used for bearing and positioning the shell base 10; the cantilever spring probe assembly includes at least one The positioning rod 4, the compression spring 3 corresponding to the positioning rod 4, at least one spring probe 9, the cantilever bracket 7 and the locking member; the positioning rod 4 is arranged on the bearing positioning assembly, and the positioning rod 4 is sheathed There is a compression spring 3; the compression spring 3 is compressed between the bearing positioning assembly and the cantilever bracket 7; the positioning rod 4 passes through the cantilever bracket 7; the locking member is used to limit the cantilever bracket 7 away from the bearing positioning assembly A certain distance position; the spring probe 9 is set on the cantilever suppor...

Embodiment 2

[0022] See attached Figure 1~3 . A COS welding fixture used in a semiconductor laser, comprising a bearing positioning assembly and at least one cantilever spring probe assembly; the bearing positioning assembly is used for bearing and positioning the shell base 10; the cantilever spring probe assembly includes at least one The positioning rod 4, the compression spring 3 corresponding to the positioning rod 4, at least one spring probe 9, the cantilever bracket 7 and the locking member; the positioning rod 4 is arranged on the bearing positioning assembly, and the positioning rod 4 is sheathed There is a compression spring 3; the compression spring 3 is compressed between the bearing positioning assembly and the cantilever bracket 7; the positioning rod 4 passes through the cantilever bracket 7; the locking member is used to limit the cantilever bracket 7 away from the bearing positioning assembly A certain distance position; the spring probe 9 is set on the cantilever suppor...

Embodiment 3

[0025] See attached Figure 1~3 . A COS welding fixture used in a semiconductor laser, comprising a bearing positioning assembly and at least one cantilever spring probe assembly; the bearing positioning assembly is used for bearing and positioning the shell base 10; the cantilever spring probe assembly includes at least one The positioning rod 4, the compression spring 3 corresponding to the positioning rod 4, at least one spring probe 9, the cantilever bracket 7 and the locking member; the positioning rod 4 is arranged on the bearing positioning assembly, and the positioning rod 4 is sheathed There is a compression spring 3; the compression spring 3 is compressed between the bearing positioning assembly and the cantilever bracket 7; the positioning rod 4 passes through the cantilever bracket 7; the locking member is used to limit the cantilever bracket 7 away from the bearing positioning assembly A certain distance position; the spring probe 9 is set on the cantilever suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com