Novel deviation rectifying device of battery pole piece slurry coating machine

A battery pole piece and deviation correction device technology, applied in the field of deviation correction device, can solve the problems of battery pole piece displacement deviation, tension instability, pole piece wrinkling, etc., to ensure production pass rate, winding accuracy, and production quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

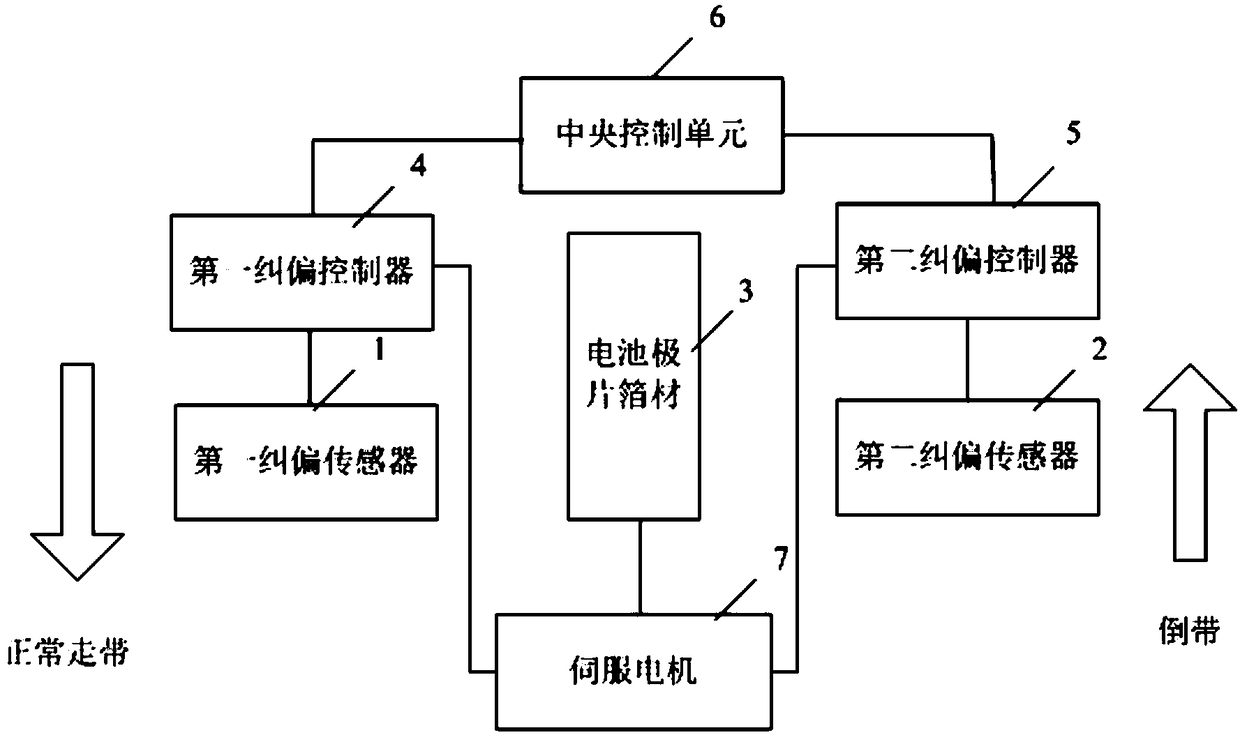

[0025] see figure 1 , the present invention provides a new type of deviation correction device for a battery pole piece slurry coating machine, including a first deviation correction sensor 1 and a second deviation correction sensor 2;

[0026] The first deflection correction sensor 1 and the second deflection correction sensor 2 are respectively located on the left and right sides of the battery pole piece foil 3 conveyed longitudinally;

[0027] The first deflection correction sensor 1 is separated from the left edge of the battery pole sheet foil 3 by a predetermined distance (for example, 0.3 mm) in the horizontal and transverse direction, and the bottom of the first deflection correction sensor 1 outputs ultrasonic waves for detection; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com