Cell taking manipulator

A technology for reclaiming manipulators and battery cells, which is applied in the directions of manipulators, program-controlled manipulators, chucks, etc., can solve problems such as affecting the accuracy of cells and the displacement deviation of superimposed positive and negative plates, so as to prevent free fall and avoid displacement deviation. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

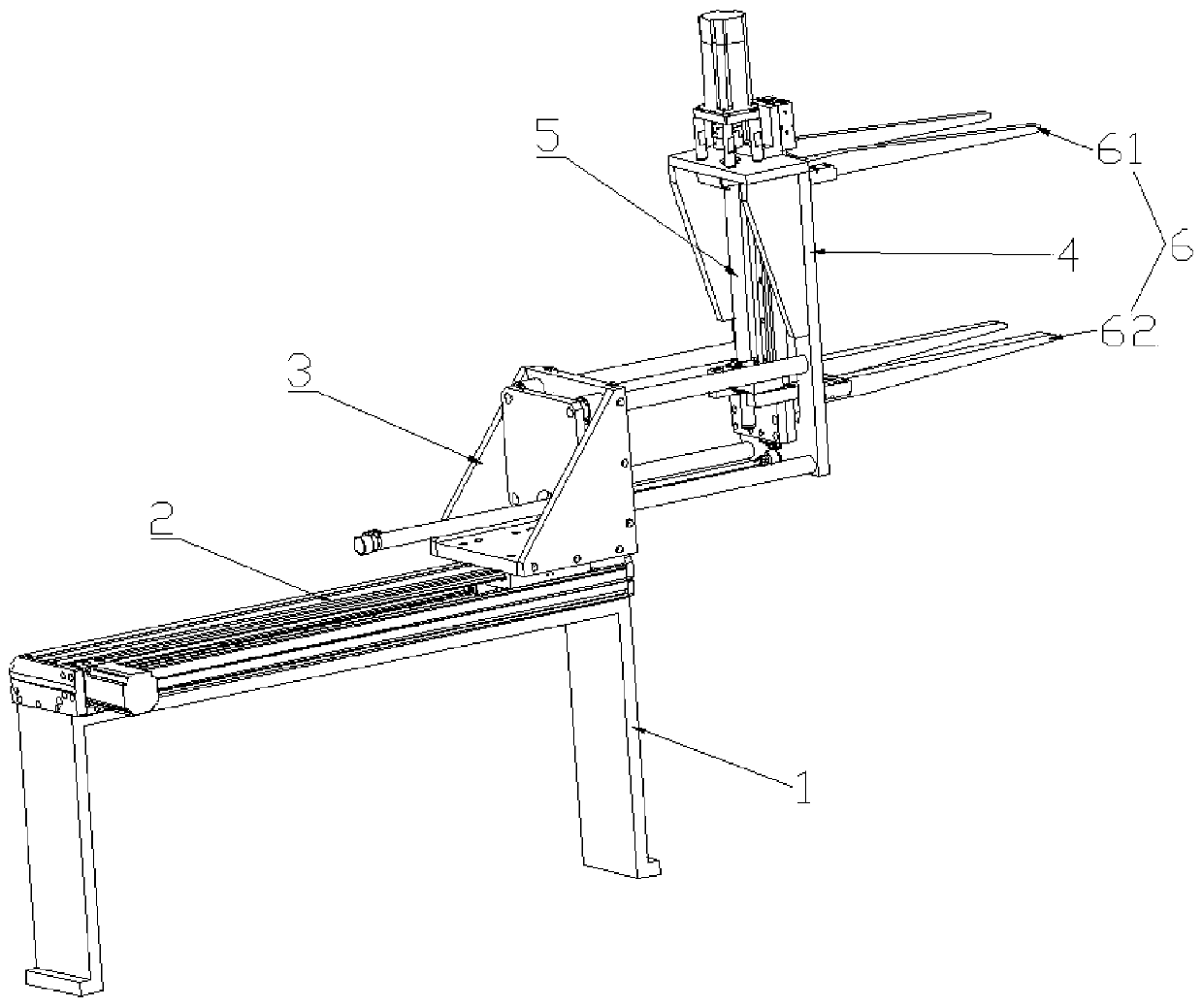

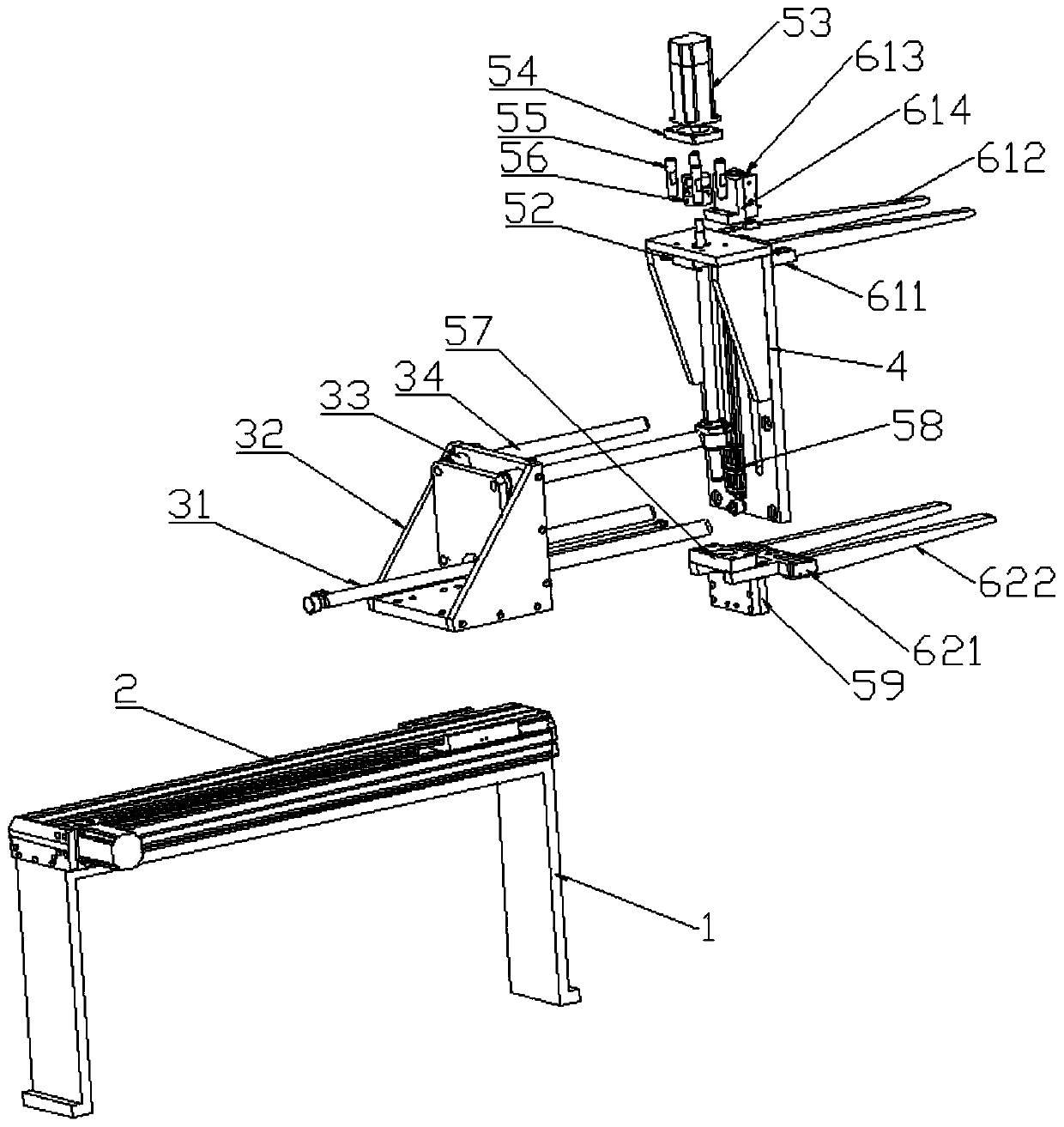

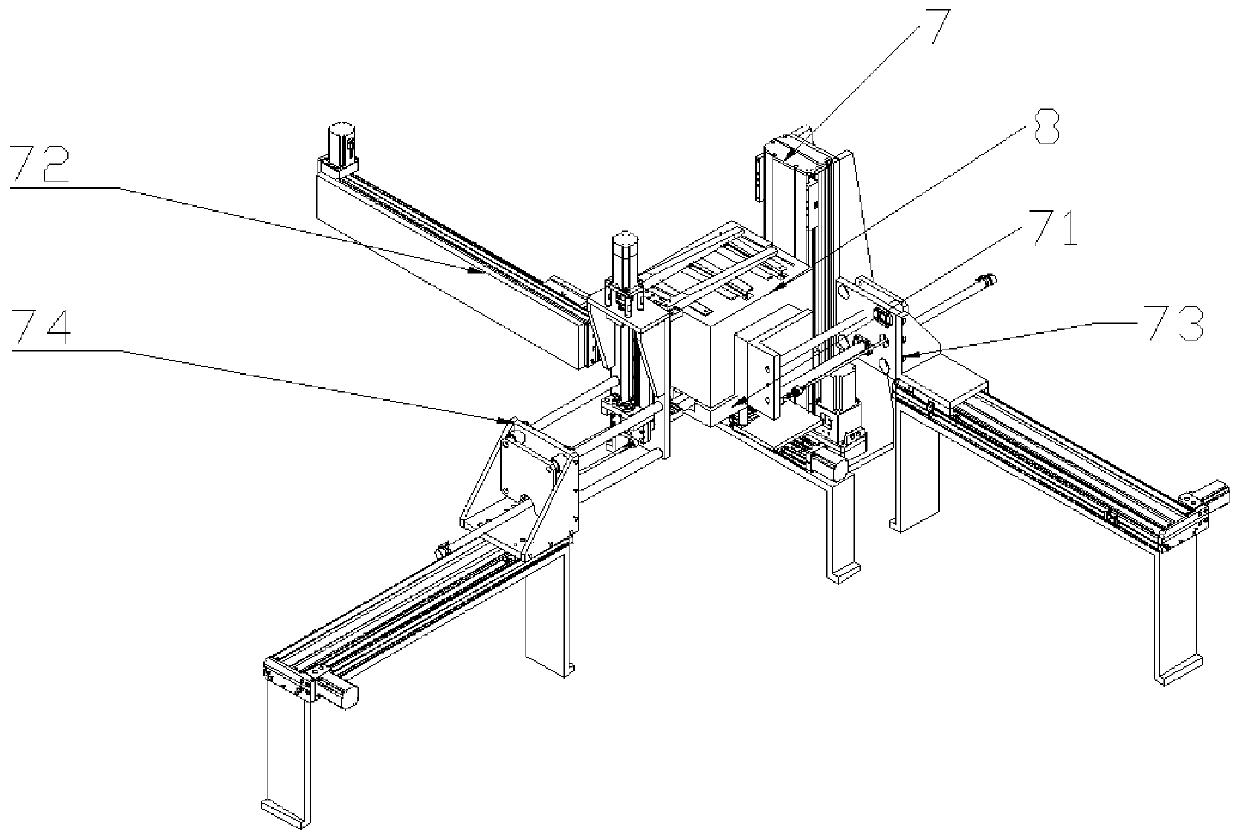

[0017] see Figure 1-2 As shown, the present invention relates to a battery retrieving manipulator 74, including a bracket 1, a lateral moving part, a lifting part 5 and a jaw part 6, the lateral moving part is arranged on the bracket 1, and the lifting part 5 is lifted The bracket 4 is connected with the transverse moving part, and the jaw part 6 is connected with the lifting part 5 .

[0018] Preferably, the lifting component 5 includes a driving motor 53, a ball screw 51, a screw connecting plate 57, a guide slide rail 58 and a slide rail connecting plate 59, and the ball screw 51 is arranged on the lifting position through a screw fixing seat 52. On the bracket 4, the ball screw 51 is rotatably installed in the screw fixing seat 52, the ball screw 51 is pierced with a screw nut, and the top of the screw fixing seat 52 is provided with a motor mounting plate 54 , the drive motor 53 is fixed on the motor mounting plate 54 through the motor mounting column, the drive motor 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com