Control method for preventing submersible linear motor from bumping

A technology of linear motor and control method, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of frequent failures and low reliability, and achieve the effect of small efficiency loss, avoidance of mover collision, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and the embodiments thereof, but the protection scope of the present invention is not limited to the scope described in the embodiments.

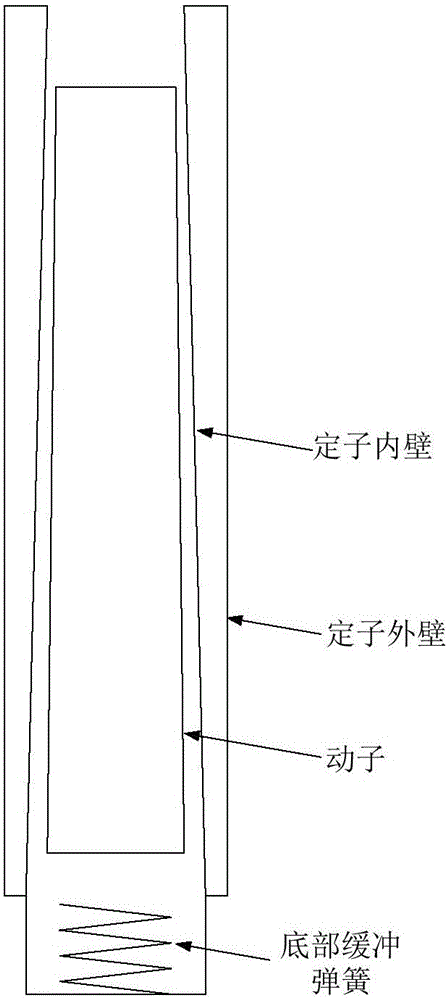

[0038] figure 1 It is a schematic structural diagram of the submersible linear motor adopted in the present invention. The submersible linear motor is a cylindrical synchronous motor, the stator coil of the linear motor is sealed in the outer cylinder, and the cylindrical mover composed of permanent magnets is surrounded by the outer cylinder. After the control cabinet inputs three-phase AC voltage to the stator of the motor, a traveling wave magnetic field will be generated in the stator, which can drive the mover to reciprocate up / down. In order to prevent the mover from going up or down from the stator, there are limit devices at the upper and lower ends of the motor stator. The limit device at the lower part of the motor adopts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com