Mechanism for snapping pin-point gate through stationary mold push plate for injection mold

A technology for injection molds and fixed molds, which is applied in the field of injection molds using fixed mold push plates to pull breakpoint gate mechanisms, which can solve the problems of low production efficiency, time-consuming, and inability to take them out at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

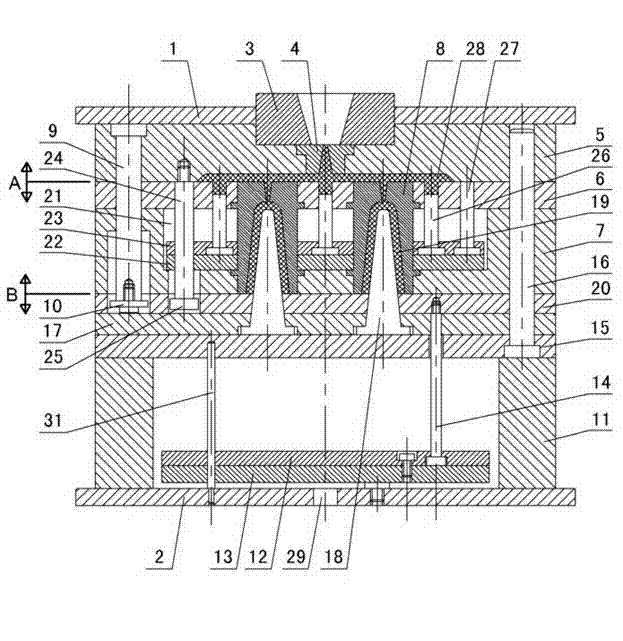

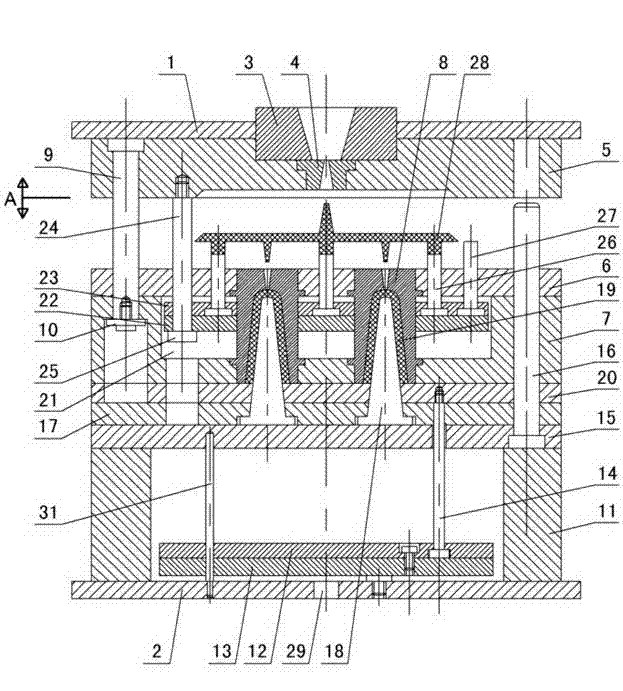

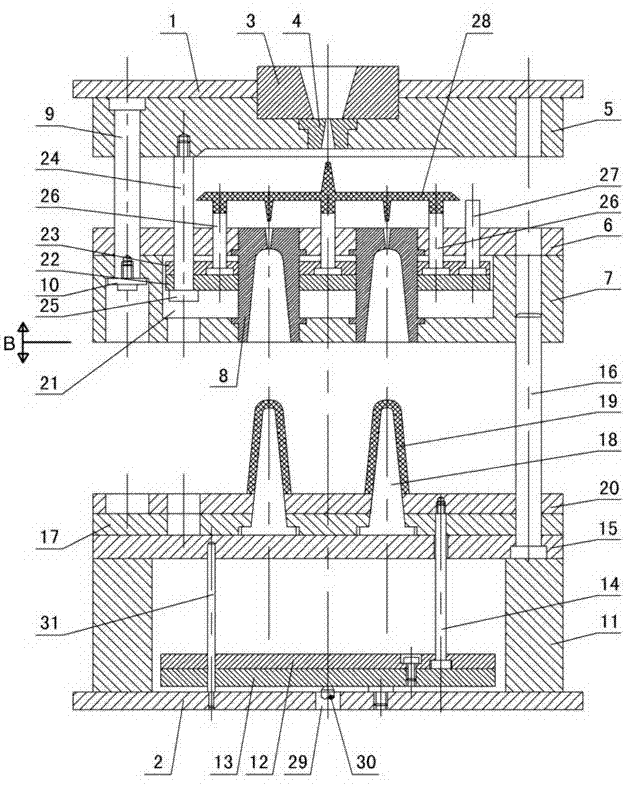

[0011] The invention relates to a gate mechanism for pulling a breaking point of an injection mold using a push plate of a fixed mold, such as figure 1 — Figure 4 As shown, it includes the upper doubler plate 1 and the lower doubler plate 2, the positioning ring 3 is installed in the upper doubler plate, the gate bushing 4 is connected under the positioning ring, the upper doubler plate 1 is connected with the runner plate 5, and the runner plate is connected under Cavity fixing plate 6, cavity plate 7 is connected under the cavity fixing plate, cavity insert 8 is fixed between the cavity plate and cavity fixing plate, fixed distance guide pillars 9 are set under the upper double plate 1, fixed distance guide pillars The baffle plate 10 is installed on the lower head, and the baffle plate is matched with the cavity plate 7. The mold feet 11 are installed on the lower double plate 2, the upper ejector plate 12 and the lower ejector plate 13 are arranged between the mold feet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com