UV solidified alkali resistant etching ink composition and uses thereof

An ink composition and alkali resistance technology, applied in the direction of ink, application, household appliances, etc., can solve the problems of poor performance, poor solubility of the cured film, difficult to remove, etc., to achieve improved alkali etching resistance, superior performance, good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

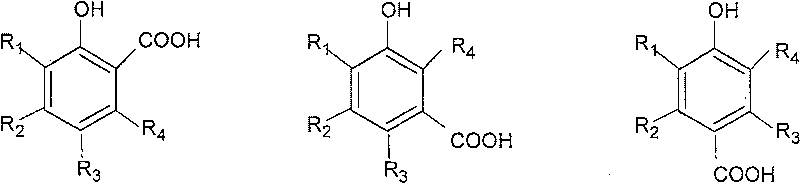

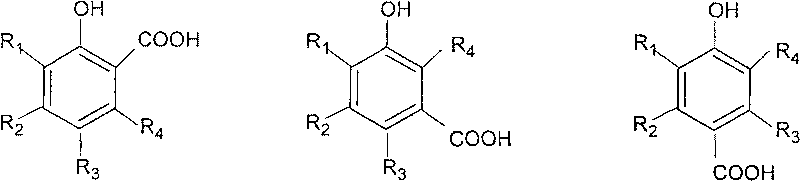

Method used

Image

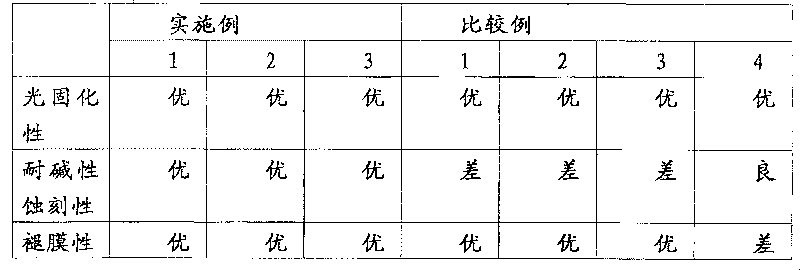

Examples

Embodiment 1

[0030] First synthesize the strong alkali water-soluble resin used in the present invention: add glycidyl methacrylate 142g, salicylic acid 138g, hydroquinone 0.5g in the reactor, heat to 95-105 ℃ for 10 hours, measure acid When the value is less than 5mg KOH / g, the reaction is stopped, and the material is cooled and discharged to obtain a wine-red liquid strong alkali water-soluble resin (a).

[0031]With the obtained strong alkali water-soluble resin (a) 40g, photosensitive diluent hydroxyethyl acrylate 23g, photosensitive initiator 907 (Ciba company photosensitizer) 6g, filler talcum powder 20g, barium sulfate 10g, pigment cyanine blue 1g , and 0.5g of dispersant, 0.5g of leveling agent and 0.2g of defoamer as auxiliary agents, mixed and ground to a fineness of less than 15 μm with a three-roller mill, to obtain a UV curing alkaline etching resistant ink composition.

Embodiment 2

[0033] Add 234g of hydroxyethyl methacrylate, 138g of salicylic acid, 0.2g of hydroquinone, and 8g of sodium bisulfate into the reactor, react at 130-140°C for 20 hours, distill 17ml of water, cool and discharge, and obtain wine Red liquid strong base water soluble resin (b).

[0034] The strong alkali water-soluble resin (b) containing only one unsaturated group in the obtained molecule was substituted for the strong alkali water-soluble resin (a) in Example 1, and the ink composition was prepared in the same manner as in Example 1.

Embodiment 3

[0036] Add 142g of glycidyl methacrylate, 138g of m-hydroxybenzoic acid, and 0.5g of hydroquinone into the reactor, heat it to 80-90°C for 8 hours, stop the reaction when the acid value is less than 5mg KOH / g, and cool it out Material, obtain wine red liquid strong alkali water-soluble resin (c).

[0037] The strong alkali water-soluble resin (c) containing only one unsaturated group in the obtained molecule was substituted for the strong alkali water-soluble resin (a) in Example 1, and the ink composition was prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com