Device for preparing lithium hydroxide micro-nano powder

A lithium hydroxide, micro-nano powder technology, applied in lithium oxide; / hydroxide, nanotechnology, nanotechnology and other directions, can solve the problem of difficulty in refining the average powder particle size, low production cost, moisture absorption and carbonization, etc. problem, to achieve the effect of low production cost, good corrosion resistance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

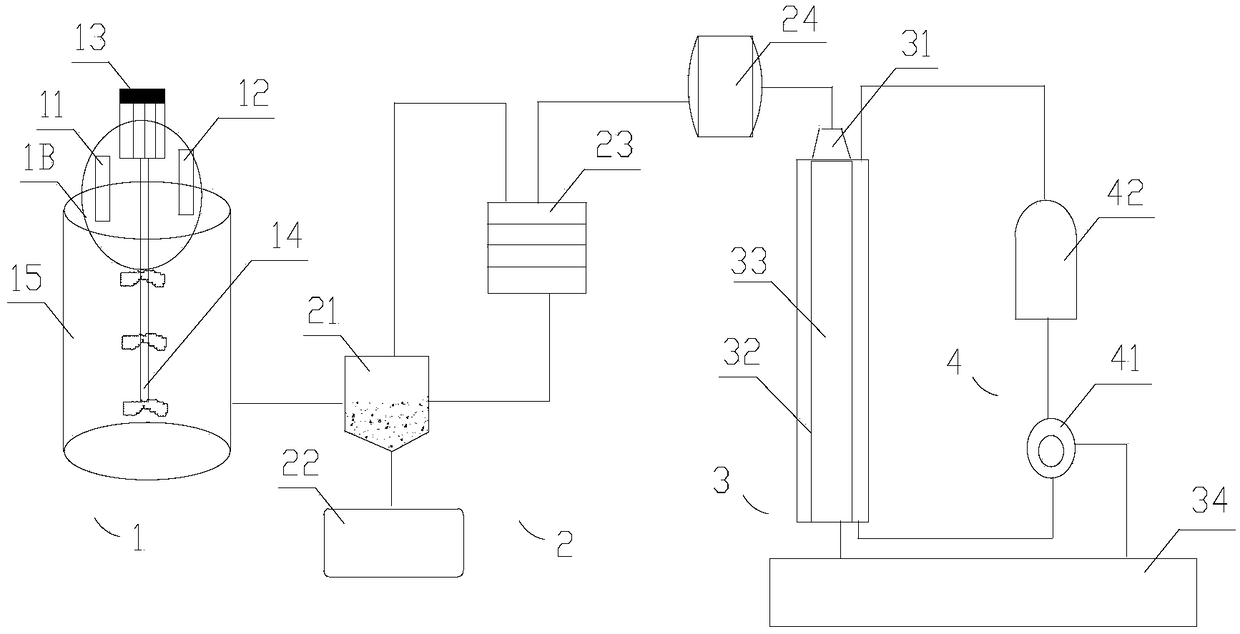

[0031] A device for preparing lithium hydroxide micro-nano powder is characterized in that it comprises a reaction system (1), a concentration control system (2), a spray drying system (3) and a gas circulation system (4).

[0032] Wherein said reaction system (1) comprises feed inlet A (11), feed inlet B (12), motor (13), agitator (14), reaction vessel (15); said feed inlet A (11 ) and the feed port B (12) are respectively symmetrically arranged on the left and right sides of the top of the reaction vessel (15) and communicate with the reaction vessel (15), the motor (13) is placed above the reaction vessel (15), and the The rotating shaft of the motor (13) is threadedly connected with the stirring rod of the stirrer (14), and the stirring rod of the stirrer (14) penetrates the top wall of the reaction vessel (15) and goes deep into the inside of the reaction vessel (15).

[0033] Described concentration control system (2) comprises settling tank (21), calcium carbonate stora...

Embodiment 2

[0044] A device for preparing lithium hydroxide micro-nano powder is characterized in that it comprises a reaction system (1), a concentration control system (2), a spray drying system (3) and a gas circulation system (4).

[0045] Wherein said reaction system (1) comprises feed inlet A (11), feed inlet B (12), motor (13), agitator (14), reaction vessel (15); said feed inlet A (11 ) and the feed port B (12) are respectively symmetrically arranged on the left and right sides of the top of the reaction vessel (15) and communicate with the reaction vessel (15), the motor (13) is placed above the reaction vessel (15), and the The rotating shaft of the motor (13) is threadedly connected with the stirring rod of the stirrer (14), and the stirring rod of the stirrer (14) penetrates the top wall of the reaction vessel (15) and goes deep into the inside of the reaction vessel (15).

[0046] Described concentration control system (2) comprises settling tank (21), calcium carbonate stora...

Embodiment 3

[0057] A device for preparing lithium hydroxide micro-nano powder is characterized in that it comprises a reaction system (1), a concentration control system (2), a spray drying system (3) and a gas circulation system (4).

[0058] Wherein said reaction system (1) comprises feed inlet A (11), feed inlet B (12), motor (13), agitator (14), reaction vessel (15); said feed inlet A (11 ) and the feed port B (12) are respectively symmetrically arranged on the left and right sides of the top of the reaction vessel (15) and communicate with the reaction vessel (15), the motor (13) is placed above the reaction vessel (15), and the The rotating shaft of the motor (13) is threadedly connected with the stirring rod of the stirrer (14), and the stirring rod of the stirrer (14) penetrates the top wall of the reaction vessel (15) and goes deep into the inside of the reaction vessel (15).

[0059] Described concentration control system (2) comprises settling tank (21), calcium carbonate stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com