Production method of chemi-mechanical pulp

A production method and technology of chemical-mechanical pulp, applied in the direction of textiles and papermaking, papermaking, water/steam pretreatment, etc., can solve the problems of reduced profits, reduced paper physical indicators, and low wood fiber usage, so as to achieve increased profits and shortened production costs. Softening time, large output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

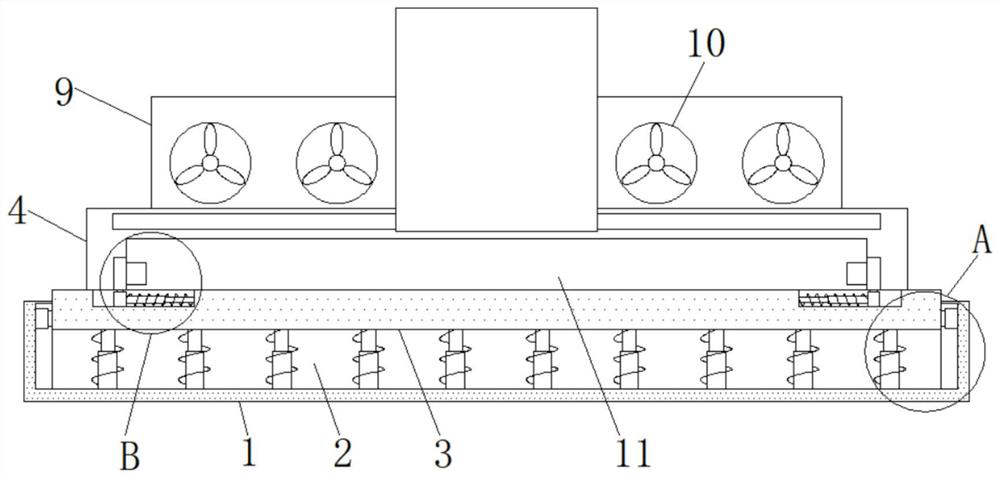

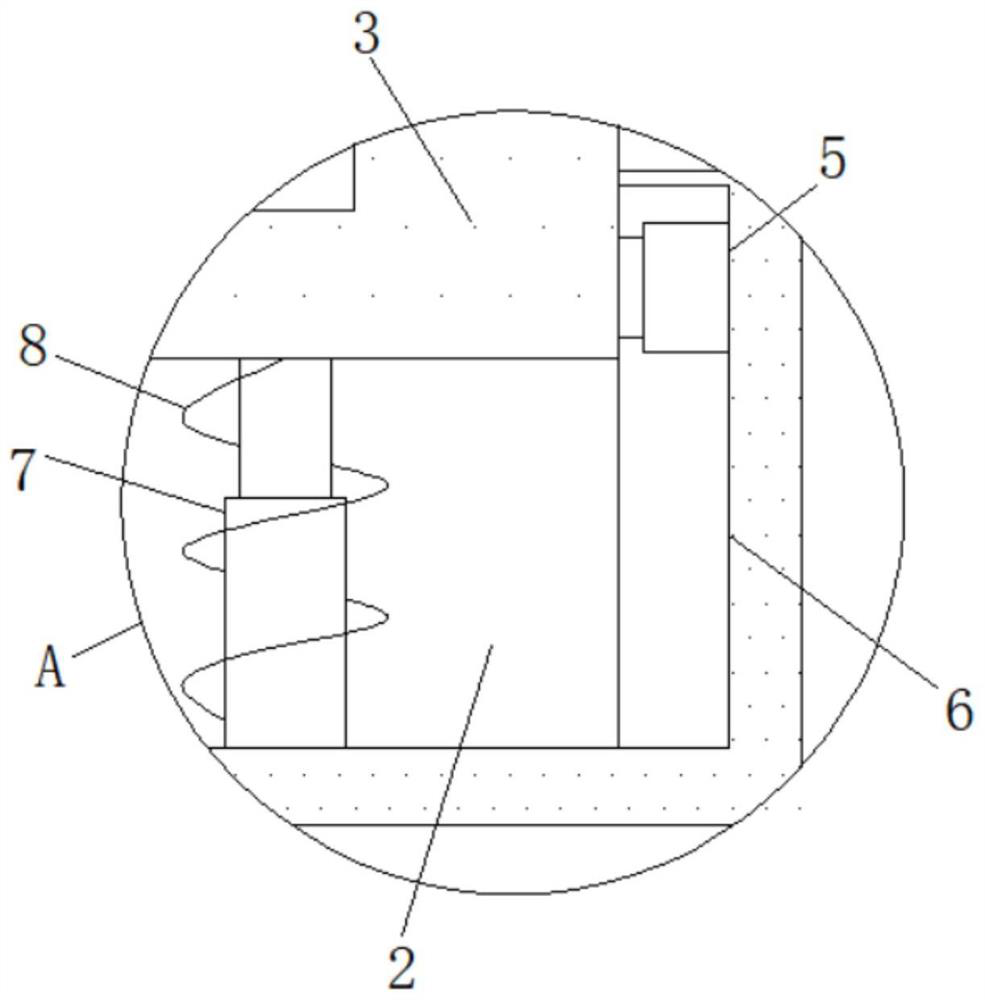

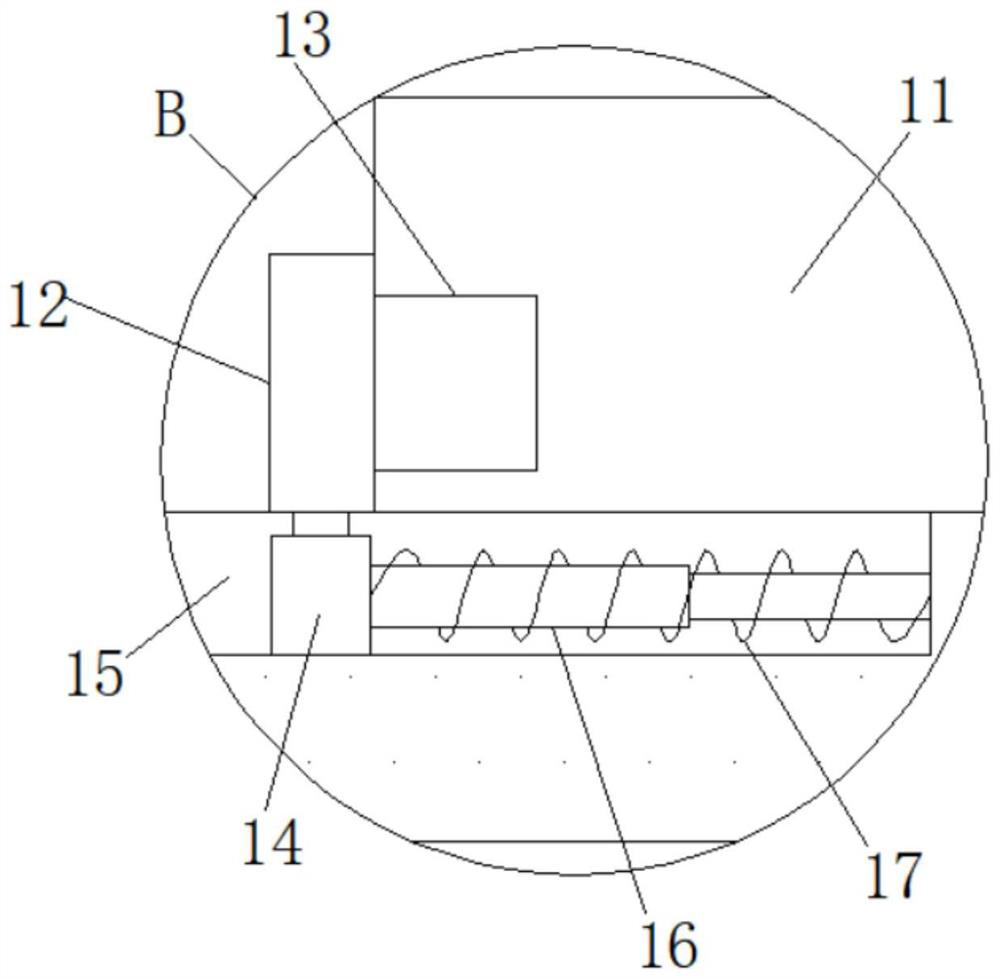

[0035] see Figure 1-3 A kind of chemical mechanical pulp production method of the present invention, comprises the following steps:

[0036] Step 1: Obtain the raw materials, and cut the raw materials into wood chips through cutting equipment;

[0037] Step 2: Clean the cut raw wood chips;

[0038] Step 3: Soften the cleaned raw wood chips;

[0039] Step 4: Add the softened raw wood chips to the thermal mill, separate the wood chips into fine fibers, and discharge the material through steam pressure spraying. The cleaning is to wash the chips with water to remove impurities in the wood chips. The softening includes:

[0040] The wood chips are screened and transported to the silo, and the output of the silo enters the thermal grinder material plug device, and then enters the cooking tank, the temperature is 110-140 degrees, the steam pressure is 0.65-0.8 MPa, and the steam is cooked for 3-5 minutes.

[0041] In the chemical-mechanical pulp production method described in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com