A safe and low-energy-consumption forming method of titanium-silicon molecular sieve spray

A technology of titanium-silicon molecular sieve and molding method, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve problems such as low feed rate, difficulty in mixing uniformly, and high spray temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 (preparation of titanium silicon molecular sieve crystallization solution and titanium silicon molecular sieve raw powder)

[0026] According to the method described in "Zeolites, 1992, Vol.12: 943-950", the nano-sized TS-1 molecular sieve crystallization solution was prepared.

[0027] Mix 382.5 g of tetraethyl orthosilicate with 178.5 g of tetrapropylammonium hydroxide, add 1046.6 g of distilled water, mix and hydrolyze at normal pressure and 60 °C for 1.0 h to obtain a hydrolysis solution of tetraethyl orthosilicate , slowly added a solution consisting of 18.7 g tetrabutyl titanate and 85 g anhydrous isopropanol under vigorous stirring, and stirred the resulting mixture at 75 °C for 3 h to obtain a clear transparent colloid. Put this into a stainless steel sealed reaction kettle, crystallize at a constant temperature at 170 °C for 72 h, and then quench it to obtain a crystallization solution of nano-sized titanium-silicon molecular sieve.

[0028] A small ...

Embodiment 2

[0029] Embodiment 2 (preparation of titanium silicon molecular sieve cluster)

[0030] Take 800 g of the titanium-silicon molecular sieve crystallization solution obtained in Example 1, add 16.8 g of a pre-agglomeration aid polyacrylamide solution with a mass fraction of 1‰, stir for a period of time, and add dilute nitric acid to adjust the pH of the crystallization solution to 7. Then suction filtration and separation can obtain millimeter-sized titanium-silicon molecular sieve clusters.

[0031] A small amount of titanium-silicon molecular sieve clusters was taken and dried overnight at 120 °C. Analysis showed that the mass fraction of titanium-silicon molecular sieve clusters was 30%. After calcining in air atmosphere at 550 ℃ for 6 h, the titanium-silicon molecular sieve raw powder was obtained. The obtained sample was subjected to XRD analysis, and there were five characteristic diffraction peaks with diffraction angles 2θ=7.8°, 8.8°, 23.2°, 23.8°, and 24.3°.

Embodiment 3

[0032] Embodiment 3 (titanium silicon molecular sieve cluster spray)

[0033] Take 74.1 g of the millimeter-sized titanium-silicon molecular sieve cluster obtained in Example 2, add 5.44 g of silica sol (mass fraction 30%), 1.146 g of white carbon black, and 19.33 g of citric acid aqueous solution (pH value is 3-5), and the slurry solidifies The content is 25%, and then beat evenly. The slurry was sprayed under the conditions of an inlet temperature of 190 °C, an outlet temperature of 70 °C, and a feed rate of 18 g / min.

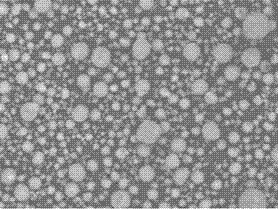

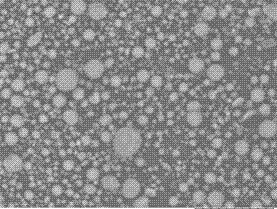

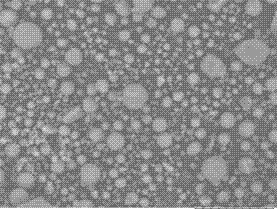

[0034] The formed particles were calcined under programmed temperature conditions, the heating rate was 5 ℃ / min, and the calcination was performed at 230 ℃ for 20 min, at 350 ℃ for 60 min, and at 720 ℃ for 3 h in an air atmosphere. The shaped titanium-silicon molecular sieve particle A is prepared. The photographs were characterized by SEM scanning electron microscope as figure 1 As shown, the shape of the formed titanium-silicon molecular sieve is circula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com