A kind of preparation method of foamed tin material

A technology of foamed tin and polyurethane sponge, applied in the field of foamed metal materials, can solve the problems of complex process flow, high raw material cost, large amount of waste water discharge, etc., and achieve the effects of simple process, improved performance and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

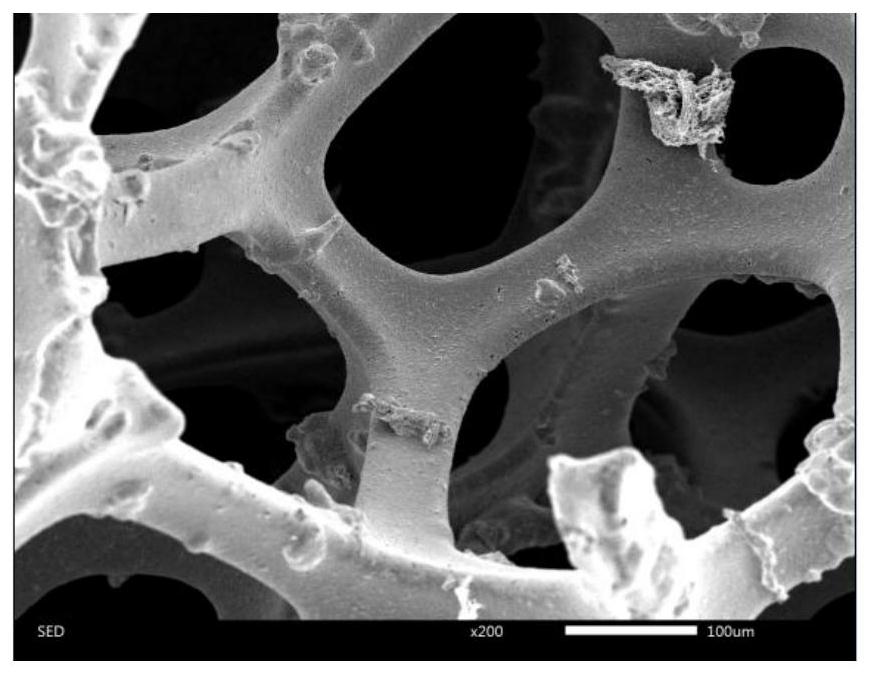

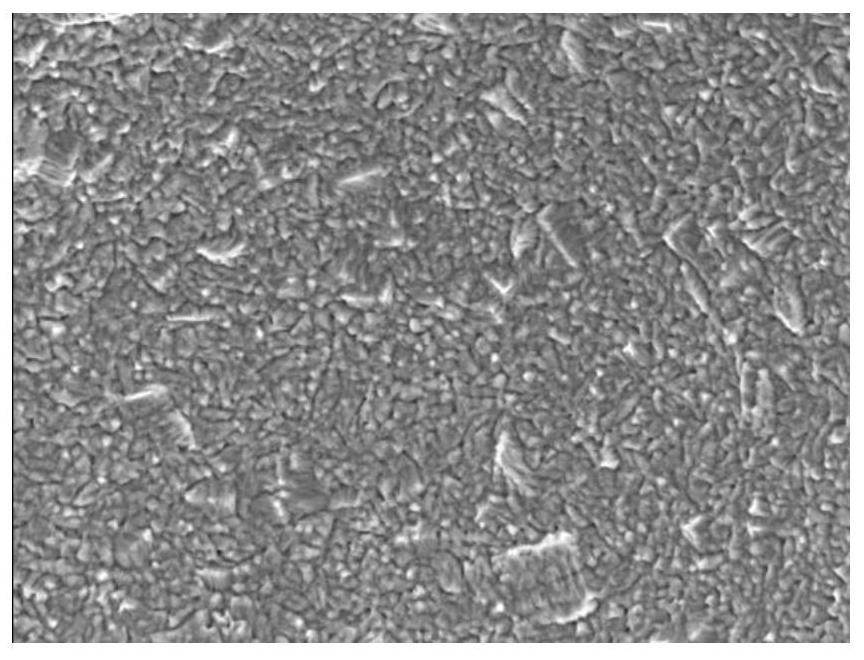

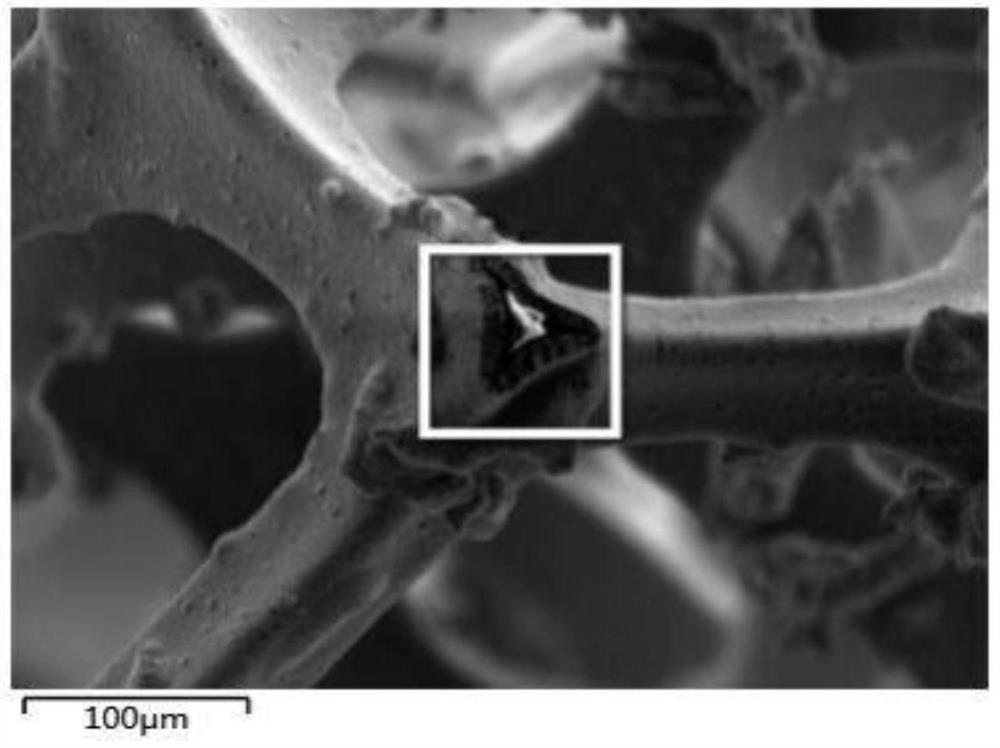

Embodiment 1

[0033] a) Vacuum magnetron sputtering nickel plating on polyurethane sponge: select polyurethane foam with a pore diameter of 110PPI and a thickness of 1.4mm, install the polyurethane foam on the magnetron sputtering equipment, close the vacuum chamber and evacuate, when the background vacuum When ≤0.11Pa, turn on the target power for 4 minutes and enter the sputtering stage, adjust the target power and argon flow, open the water circulation valve to reduce the target temperature, prevent the polyurethane sponge from vaporizing or deforming at high temperatures, and turn on the sputtering target power Carry out sputtering, the sputtering target is a square nickel target, the tape speed is 7m / min, and the working vacuum is 0.9Pa, the target power is 2.5kW, and the argon flow rate is 80sccm, and the sputtering is 3 times, and then the working vacuum is Sputter once at 0.4Pa, target power 3.5kW, argon gas flow 120sccm, the entire sputtering process is over, first turn off the targ...

Embodiment 2

[0036] a) Vacuum magnetron sputtering nickel plating on polyurethane sponge: select polyurethane foam with a pore diameter of 140PPI and a thickness of 0.9mm, install the polyurethane foam on the magnetron sputtering equipment, close the vacuum chamber and evacuate, when the background vacuum When ≤0.11Pa, turn on the target power for 5 minutes and enter the sputtering stage, adjust the target power and argon flow, open the water circulation valve to reduce the target temperature to prevent the polyurethane sponge from vaporizing or deforming at high temperatures, and turn on the sputtering target power to carry out Sputtering, the sputtering target is a square nickel target, the tape speed is 6.0m / min, the working vacuum is 0.8Pa, the target power is 2.8kW, and the argon gas flow rate is 90 sccm, and then the working vacuum is Sputter 3 times at 0.3Pa, target power 4.0kW, argon gas flow rate 140sccm, the whole sputtering process is over, first turn off the target power, then t...

Embodiment 3

[0039] a) Vacuum magnetron sputtering nickel plating on polyurethane sponge: select polyurethane foam with a pore size of 80PPI and a thickness of 4mm, install the polyurethane foam on the magnetron sputtering equipment, close the vacuum chamber and evacuate, when the background vacuum degree≤ At 0.11Pa, turn on the target power for 8 minutes and enter the sputtering stage, adjust the target power and argon flow, open the water circulation valve to reduce the target temperature to prevent the polyurethane sponge from vaporizing or deforming at high temperatures, and turn on the sputtering target power for sputtering Sputtering, the sputtering target is a square nickel target, the tape travel speed is 4.0m / min, the working vacuum is 0.3Pa, the target power is 3.0kW, and the argon gas flow rate is 120sccm. Pa, the target power is 4.5kW, and the argon gas flow rate is 160sccm and sputtering 4 times. After the whole sputtering process is over, first turn off the target power, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com