Automatic casting system

An automation system and technology of casting machines, applied in the field of casting equipment, can solve the problems of low degree of automation, high degree of danger and harsh working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

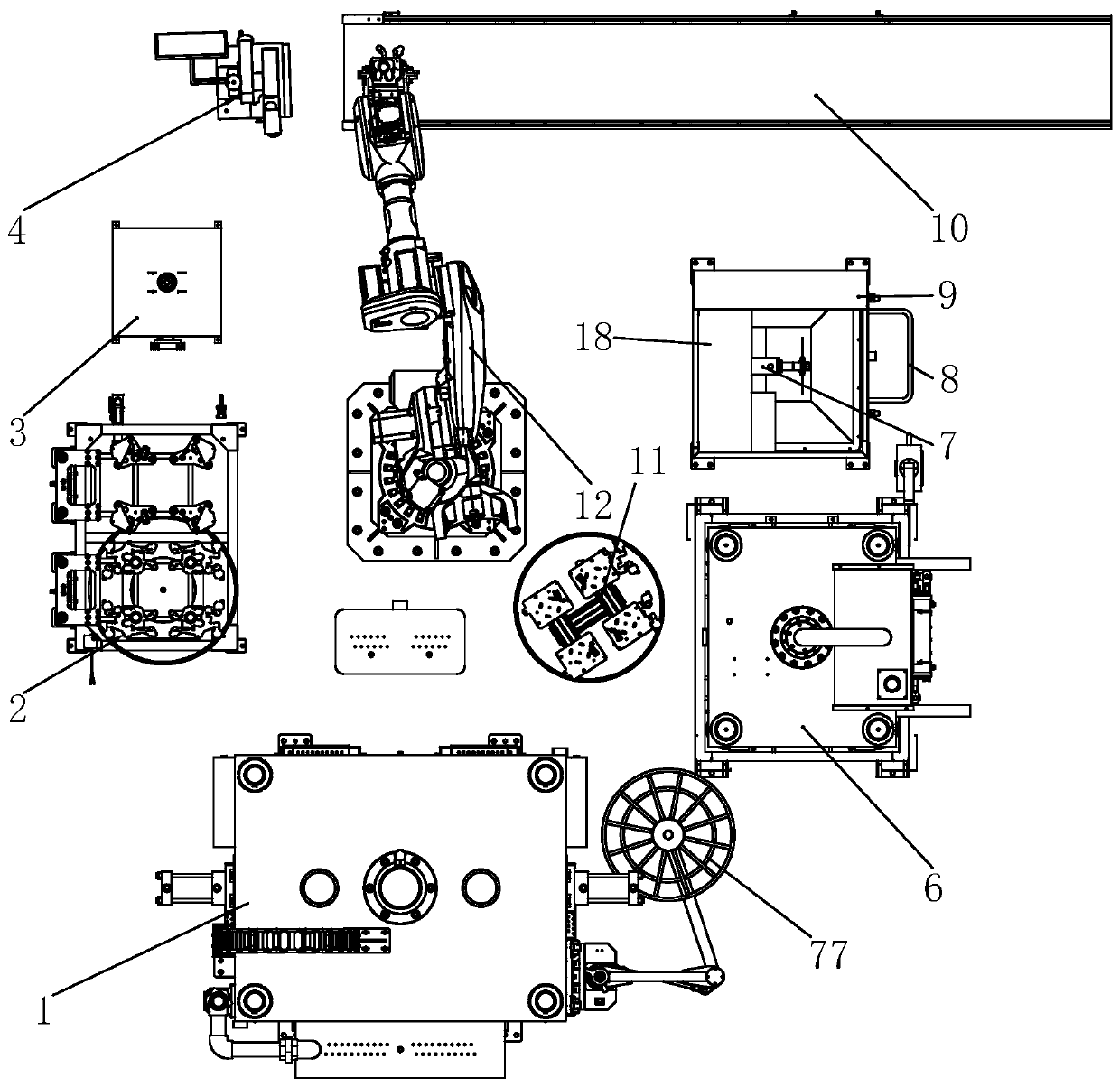

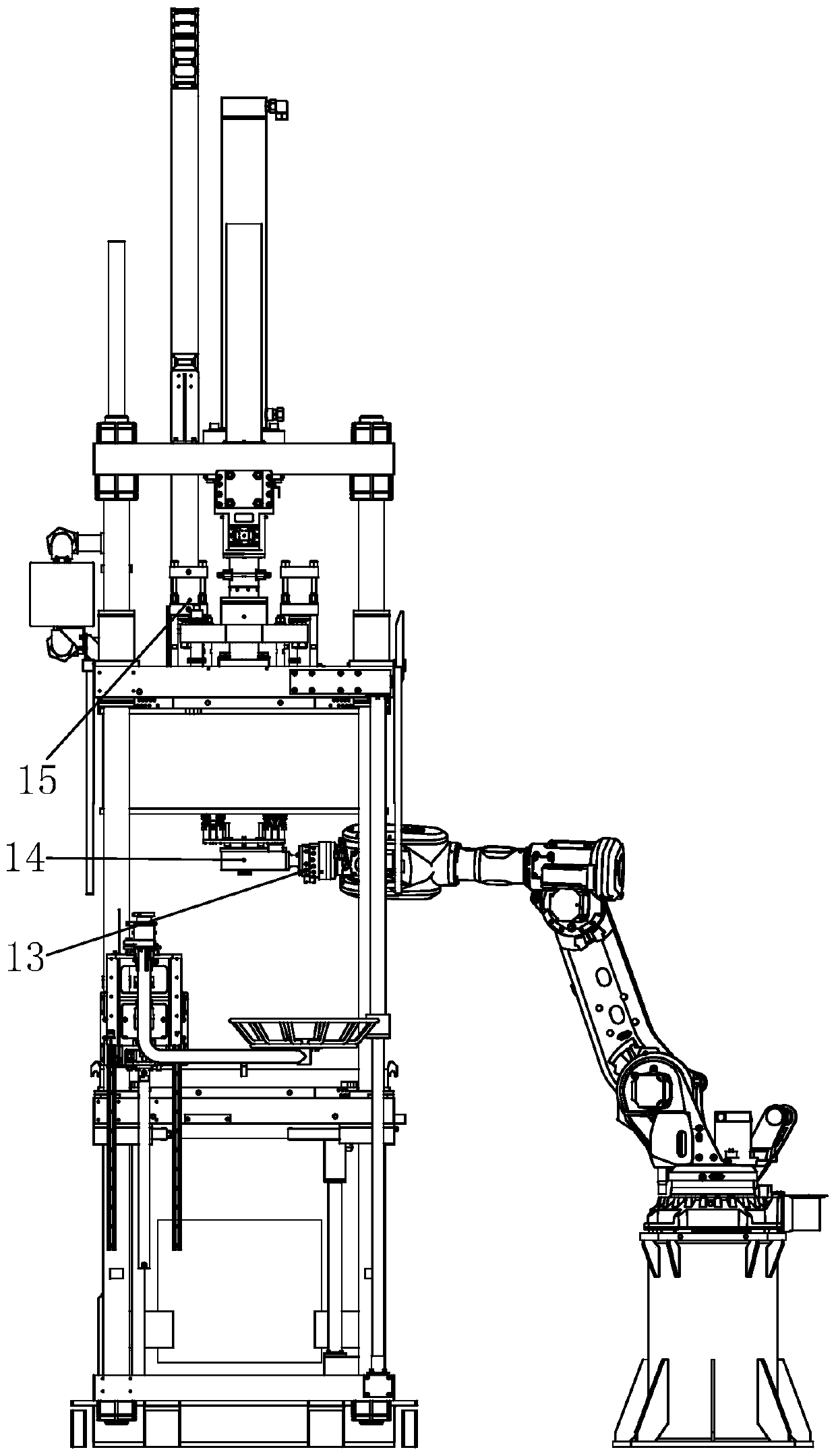

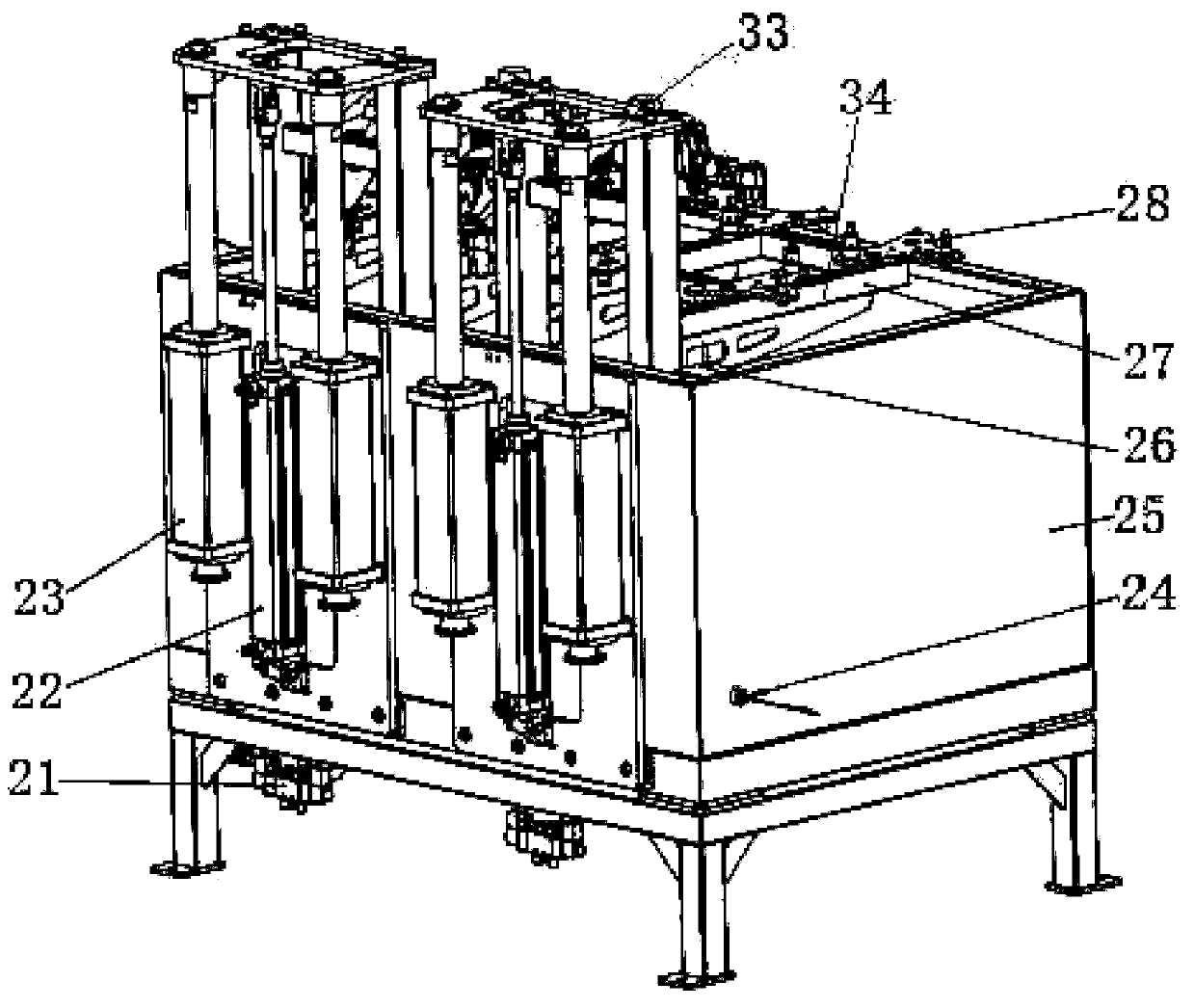

[0071] Embodiment: A kind of foundry automation system

[0072] Refer to attached figure 1 To attach Figure 8 As shown, this implementation is specifically a differential pressure casting automation system, including a differential pressure casting machine 1, a robot 12, a casting cooling unit 2, a tooling warehouse 3, a casting grabbing tool 14, a casting edge trimming unit 6, a sawing unit 18, a casting Marking unit 4, casting conveying unit 10 and casting auxiliary turntable 11; centered on robot 12, differential pressure casting machine 1, casting cooling unit 2, tooling warehouse 3, casting conveying unit 10, casting edge trimming unit 6, sawing unit 18. The casting marking unit 4 and the casting auxiliary turntable 11 are arranged around the robot, wherein the robot 12 is placed between the differential pressure casting machine 1 and the casting conveying unit 10 .

[0073] The differential pressure casting machine 1 is a four-column differential pressure casting mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com