Production automation test method of industrial Ethernet switch

A technology of automated testing and switches, which is applied in data exchange networks, digital transmission systems, electrical components, etc., can solve problems such as a large amount of training investment, an increase in the number of debugging personnel, and high complexity of debugging and inspection work, so as to reduce personnel and training investment , reduce personnel and training investment, and improve the effect of automated production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

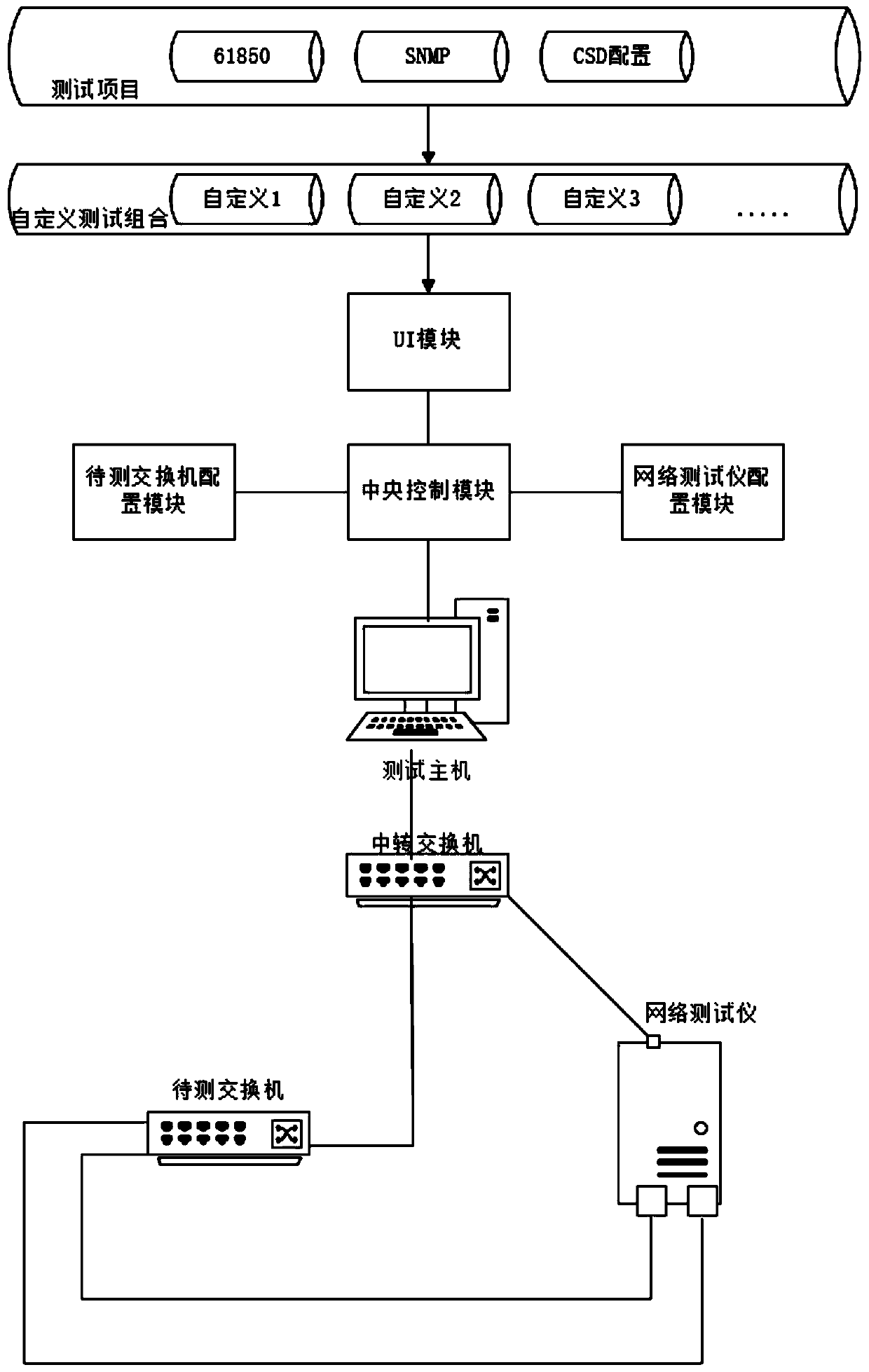

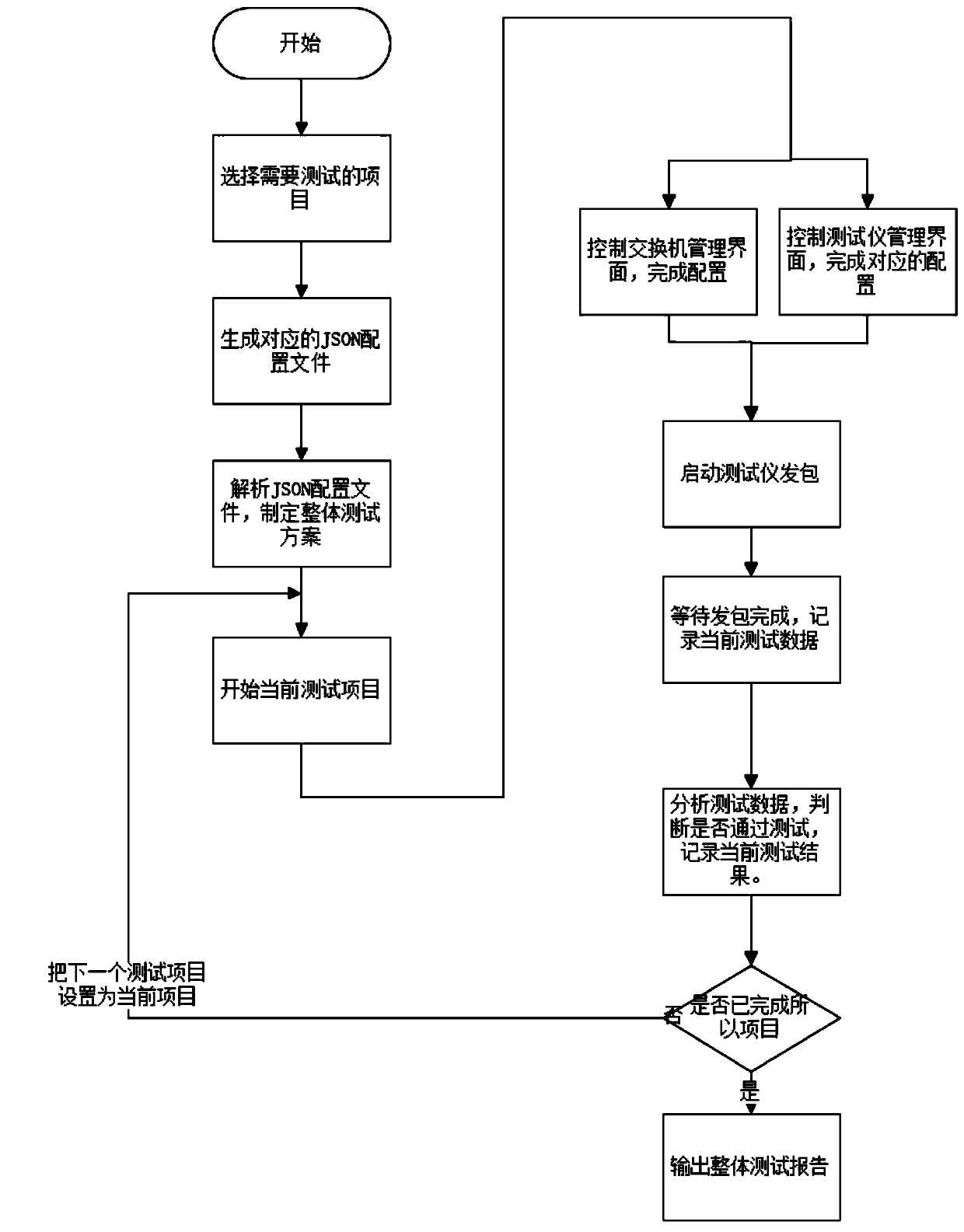

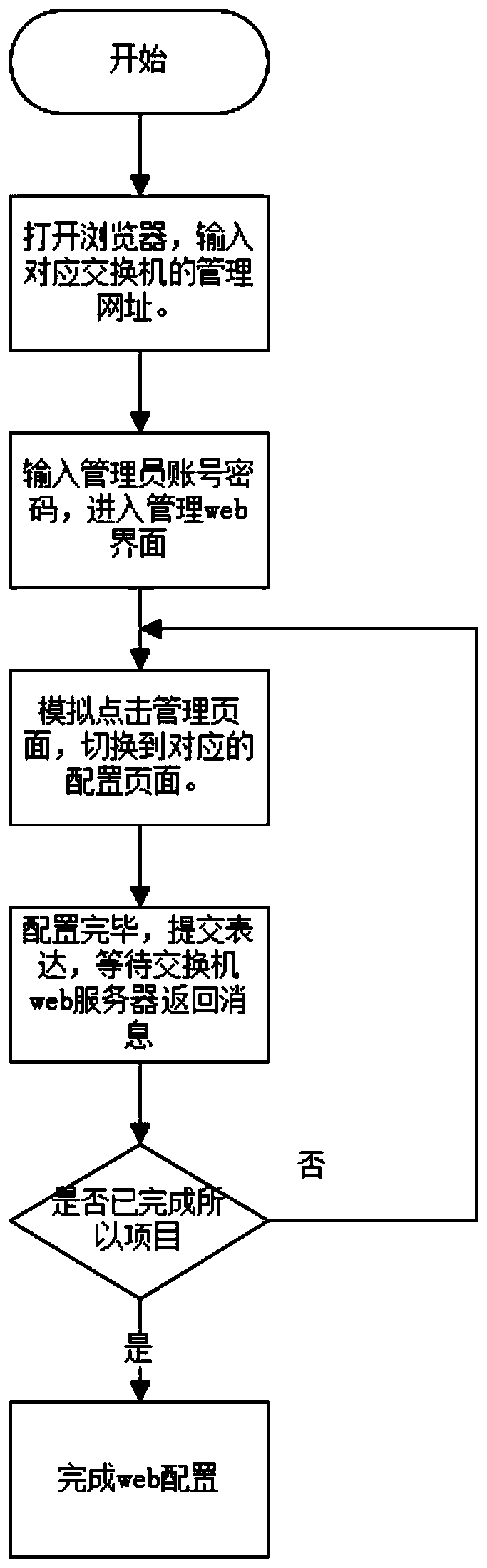

[0022] Such as figure 1 As shown, the production automation test method of the industrial Ethernet switch of the present invention adopts the test system of the industrial Ethernet switch, and the industrial Ethernet switch includes a test host, a network tester, and a switch (ie, the switch to be tested). The test host is connected to the network tester and the switch, and the network tester is connected to the switch. The HTTP (HyperText Transfer Protocol) protocol is used to establish a communication connection between the test host and the network tester; the communication connection between the test host and the switch management interface is established through the HTTP protocol; the switch and the network tester pass Ethernet data frames to communicate.

[0023] The production automation test system of the industrial Ethernet switch of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com