Double-rod shrinking machine and method for shrinking casing by using same

A shrinking machine and shrinking technology, which is applied in the fields of sausage casings, slaughtering, food science, etc., can solve the problems of being unsuitable for large-scale industrial production, slow filling speed, and low yield rate of collagen casings, so as to improve the efficiency of automated production , Improve the degree of automation and enhance the effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

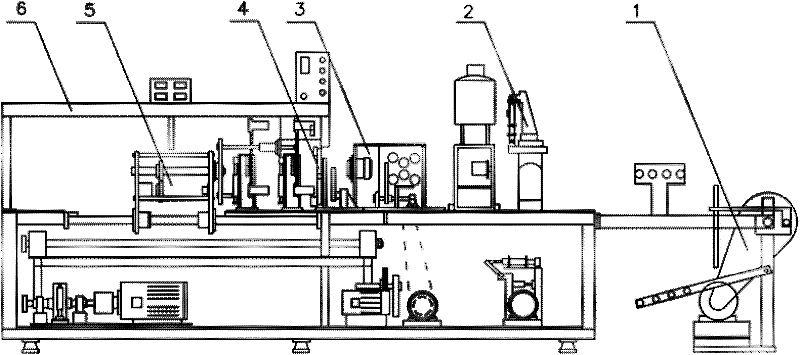

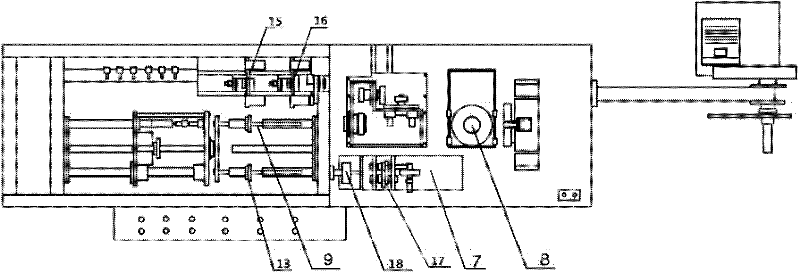

[0044] The double-rod shrinking machine shrinks a certain length of collagen casing into a shorter section, and its structure is as follows: figure 1 with figure 2 Shown, comprise frame 6 and be installed in the clothes transmission mechanism 1 on the frame 6, meter mechanism 2, retraction mechanism 3, cutter mechanism 4, turntable mechanism 5 and undress mechanism 7.

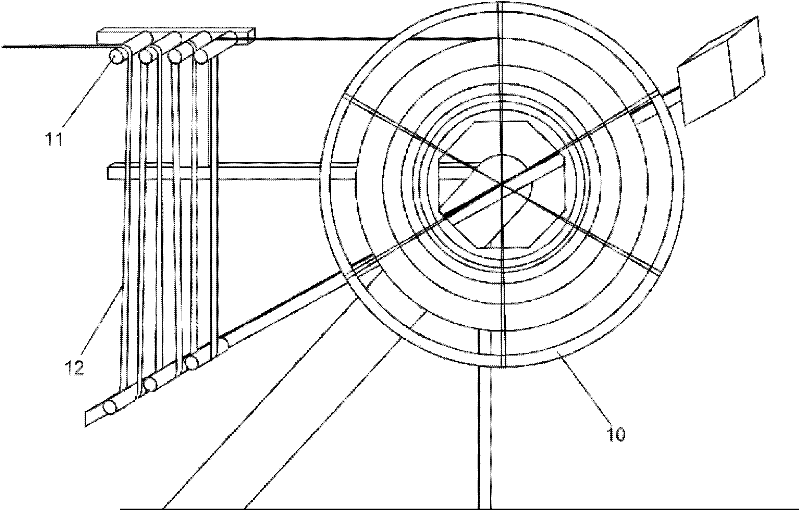

[0045] Wherein, the clothes feeding transmission mechanism 1 is installed on one end of the frame 6, and is used to transmit the casing 12 to the meter counting mechanism 2; the clothes feeding transmission mechanism 1 includes a first transmission mechanism and The driven casing wheel 10 is also provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com