Servo-controlled winding tension attenuation apparatus, winding machine and control method therefor

An attenuation device and servo control technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as unsatisfactory tensioners, damage, and lower yields, so as to improve automated production efficiency and vertically up and down The effect of smooth movement and stable and reliable control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Winding machine embodiment:

[0033] The embodiment of the winding machine is mainly aimed at the winding machine of the present invention. Since the winding machine of the present invention adopts the servo-controlled winding tension attenuation device of the present invention, the embodiment of the tension attenuation device has been described in the description of the embodiment of the winding machine. explained.

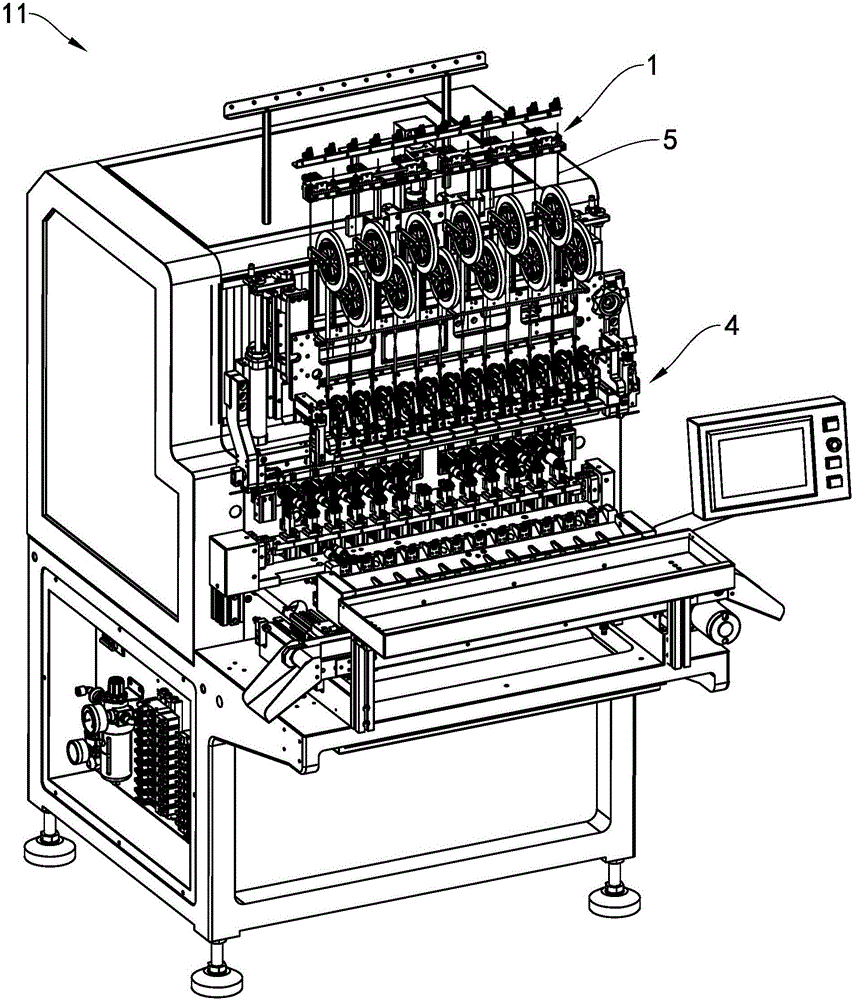

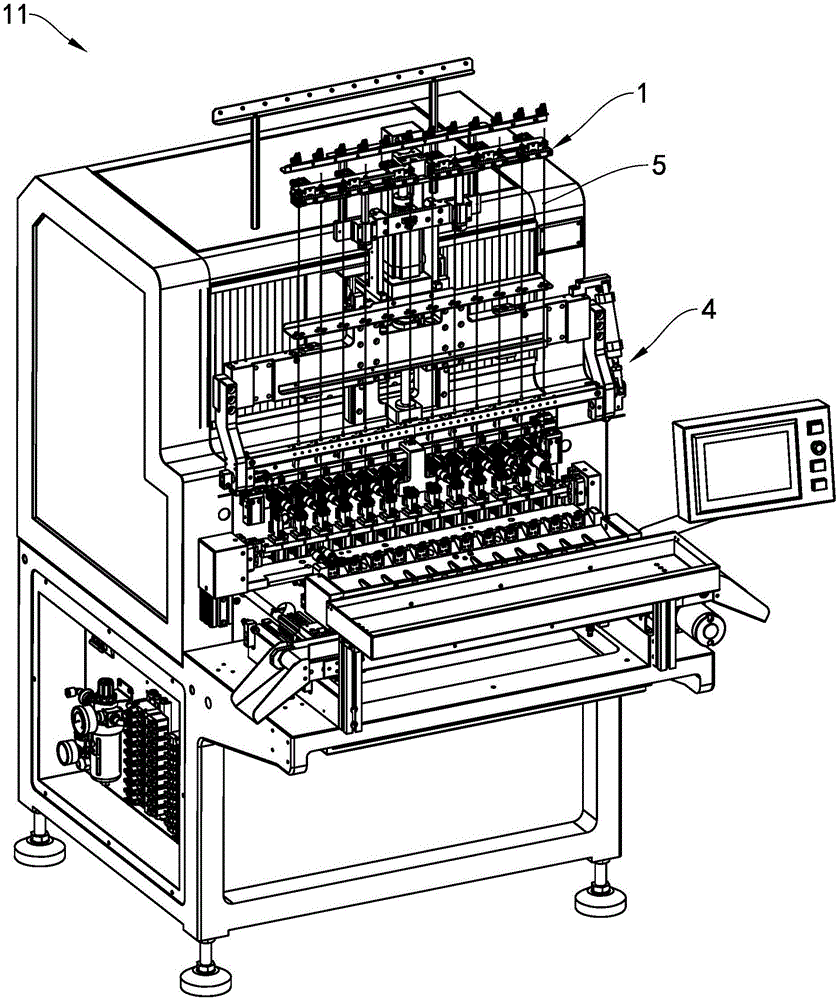

[0034] see figure 1 and figure 2 The winding machine 11 includes a winding mechanism 4 and a servo-controlled winding tension attenuation device 1. The winding mechanism 4 is used to control the transmission of the enameled wire or the insulated wire 5 and wind the enameled wire or the insulated wire 5 on the workpiece, and the tension attenuation The device 1 is used to adjust the tension of the enameled wire or the insulated wire 5 .

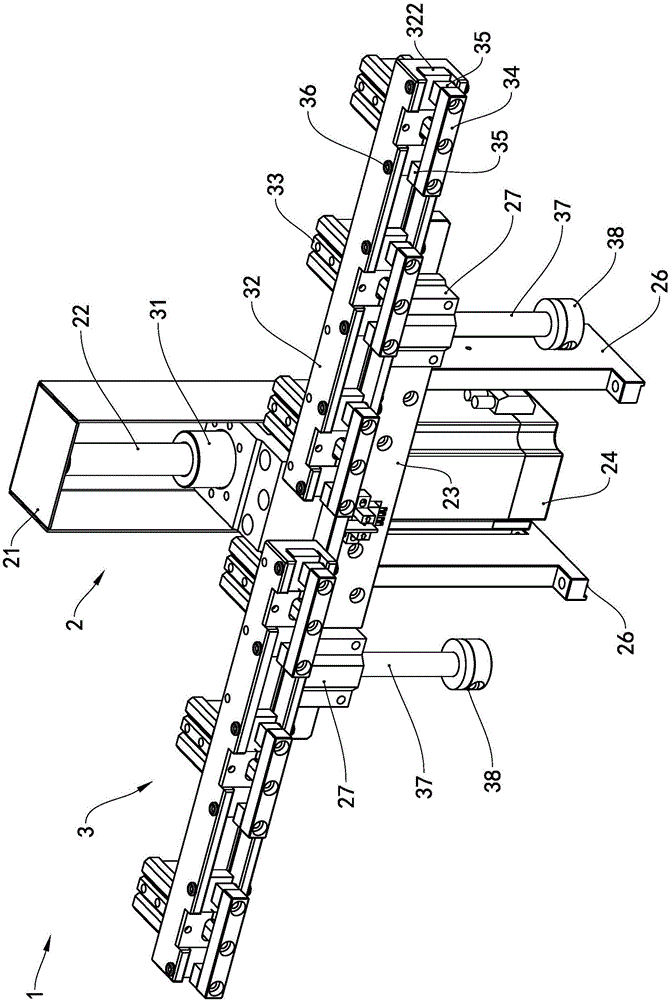

[0035] see image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , The tension attenuation device 1 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com