Ground roller type coiling and uncoiling device

A technology of take-up and take-up and ground rollers, which is applied in the field of large-diameter take-up and discharge devices, can solve the problems of single use environment and achieve the effect of simple structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

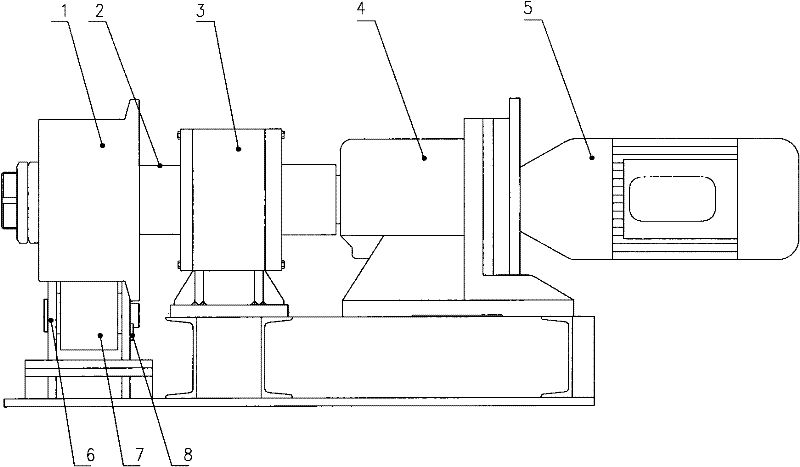

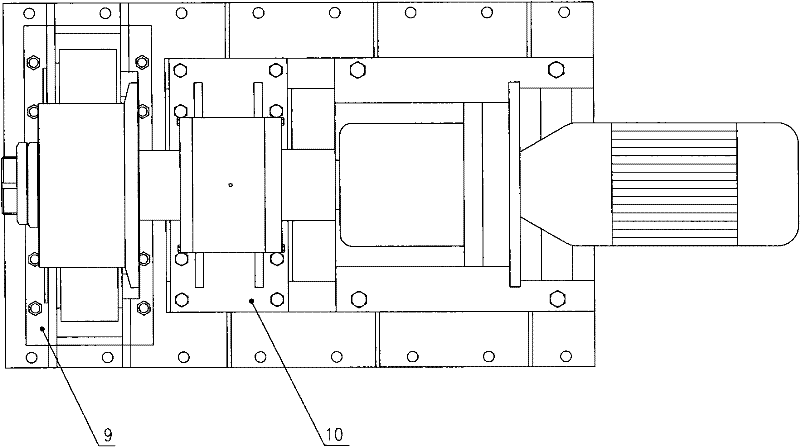

[0010] like figure 1 As shown, there are four groups of friction wheels 1, which drive the reels that need to rotate. The friction wheel limit sleeve 2 can axially and radially limit the friction wheel shaft. The bearing seat 3 contains bearings to support the bearings. The motor 5 is used together with the reducer 4, and the driving motor 5 is controlled by frequency conversion to realize the synchronous movement of each friction wheel 1. The support wheel shaft 6 is the center axis of the support wheel, and supports the friction wheel 1 with the support wheel group 7. One friction wheel 1 is matched with three A supporting wheel; the shaft end baffle 8 carries out axial and radial spacing to the friction wheel shaft, the supporting wheel base 9 fixes the supporting wheel group 7, and the take-up and pay-off base 10 fixes the whole take-up and pay-off equipment.

[0011] When the ground roller take-up and pay-off is working, fix it on the deck through the bolts at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com