Polysulphone nanometer fiber polymer membrane and preparation method as well as application thereof

A nanofiber, polymer membrane technology, applied in fiber processing, separation methods, chemical instruments and methods, etc., can solve the problems of complex preparation process, and achieve the effect of large specific surface area and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

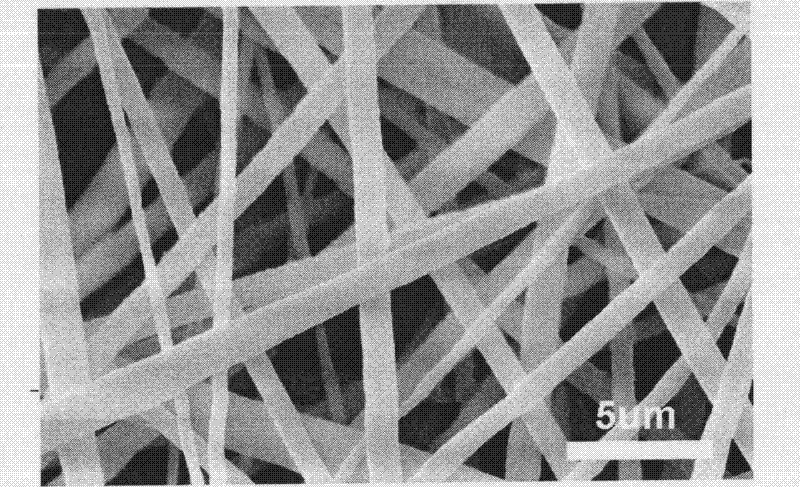

[0039]Dissolve 15g of polysulfone (weight-average molecular weight: 75,000) in 60g of N,N-dimethylformamide, and stir magnetically at a temperature of 50°C for 24 hours to obtain a clear and transparent polysulfone spinning solution, wherein polysulfone spinning The mass concentration of polysulfone in the silk solution is 20wt%. The polysulfone spinning solution is placed in the syringe of the electrospinning equipment; the stainless steel spinneret connected to the syringe through the raw material delivery pipeline is fixed, and the spinneret is placed between the spinneret and the polished stainless steel drum receiver The distance is adjusted to be 15cm, and spinning is carried out at a temperature of 20°C and a humidity of 50%; wherein, the polysulfone spinning solution is injected into the spinneret at a speed of 0.5ml / h under the action of a syringe pump. A 12kV DC high-voltage electric field is applied between the spinneret and the grounded drum receiver, and the polys...

Embodiment 2

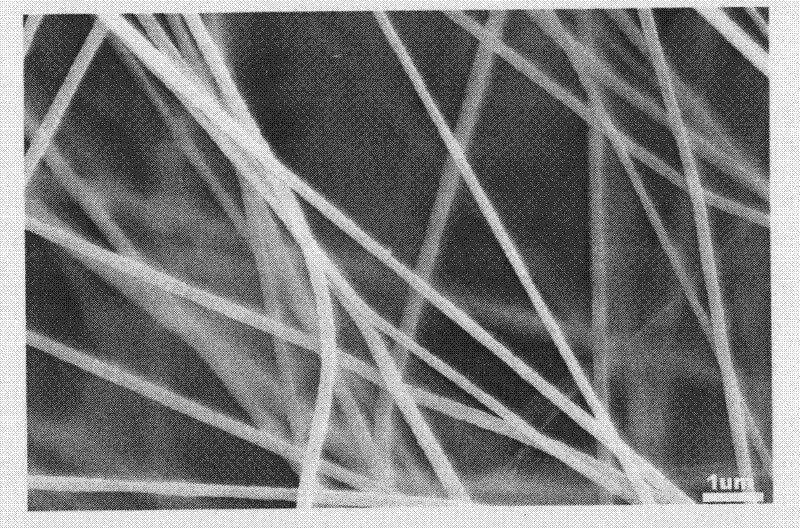

[0042] Dissolve 18g of polysulfone (weight-average molecular weight: 75,000) in 82g of N,N-dimethylformamide, and stir magnetically at a temperature of 50°C for 24 hours to obtain a clear and transparent polysulfone spinning solution, wherein polysulfone spinning The mass concentration of polysulfone in the silk solution is 18wt%. The polysulfone spinning solution is placed in the syringe of the electrospinning equipment; the stainless steel spinneret connected to the syringe through the raw material delivery pipeline is fixed, and the spinneret is placed between the spinneret and the polished stainless steel drum receiver The distance is adjusted to be 25cm, and spinning is performed at a temperature of 18°C and a humidity of 55%. Wherein, the polysulfone spinning solution is injected into the spinneret at a speed of 5ml / h under the action of a syringe pump. A 20kV DC high-voltage electric field is applied between the spinneret and the grounded drum receiver, and the polysu...

Embodiment 3

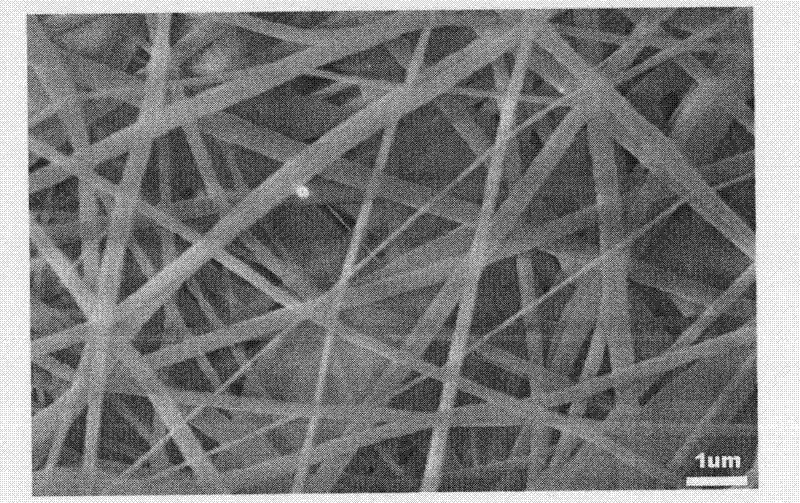

[0045] Dissolve 15g of polyethersulfone (weight-average molecular weight: 53,500) in 50.22g of N, N-dimethylformamide, and stir magnetically at a temperature of 50°C for 24 hours to obtain a clear and transparent polyethersulfone spinning solution, wherein, The mass concentration of polyethersulfone in the polyethersulfone spinning solution is 23wt%. The polyethersulfone spinning solution is placed in the syringe of the electrospinning equipment; the stainless steel spinneret connected to the syringe through the raw material delivery pipeline is fixed, and the spinneret is placed between the spinneret and the polished stainless steel drum receiver The distance between them is adjusted to be 10cm, and the spinning is carried out at a temperature of 30°C and a humidity of 65%. Wherein, the polyethersulfone spinning solution is injected into the spinneret at a speed of 1ml / h under the action of a syringe pump, A 15kV DC high-voltage electric field is applied between the spinneret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com