Straw secondary chopping and spilling machine

A technology of straw and frame, which is applied in the field of crop straw secondary chopping and spreading machine, which can solve the problems that the ground roller is easy to stick to clay and grass, does not reach the user, and the height of stubble is cut.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below in conjunction with the drawings:

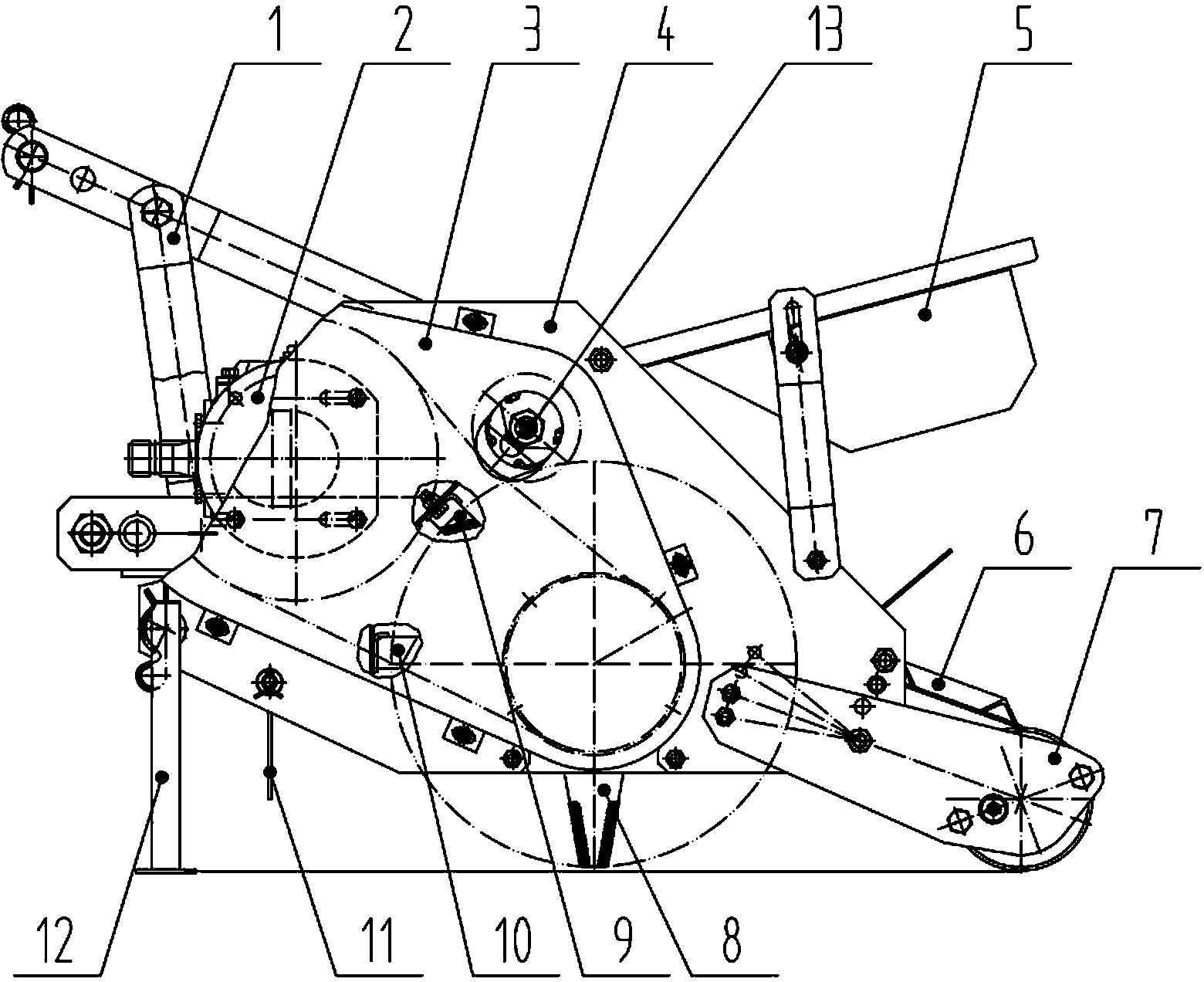

[0012] The straw secondary shredding and spraying machine is composed of a suspension frame 1, a frame 4, a leg 12, and an assembly connection of various parts. It is characterized in that the frame 4 is diamond-shaped as a whole, and the left top of the frame 4 is connected to the suspension frame 1. The bottom is connected to the leg 12, the upper right, the bottom of the frame 4 and the front of the leg 12 are respectively provided with a splitter assembly 5, a shredder shaft assembly 8 and a grass curtain 11, the front and the middle of the back of the frame 4 The upper fixed knife row 9 and the lower fixed knife row 10 are respectively arranged from top to bottom; the transmission box assembly 2 is located inside the frame 4 on the side of the suspension frame 1, and the transmission box assembly 2 and the ground roller assembly 7 are separated by Belt drive connection, belt pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com