Method for measuring load threshold of geotechnical packing accumulated deformation state under cyclic loading

A cyclic loading and threshold technology, which is applied in the direction of applying repeated force/pulsating force to test the strength of materials, can solve the lack of clear criteria for the load threshold of the cumulative deformation evolution state, the randomness and subjectivity of the test results, and the professionalism of the test personnel Higher requirements and other problems, to achieve the effect of objective test results, good mechanical response and deformation law, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0041] A specific embodiment of the present invention is: a method for determining the load threshold value of the cumulative deformation state of geotechnical filler under cyclic load, comprising the following steps:

[0042] A. Test preparation

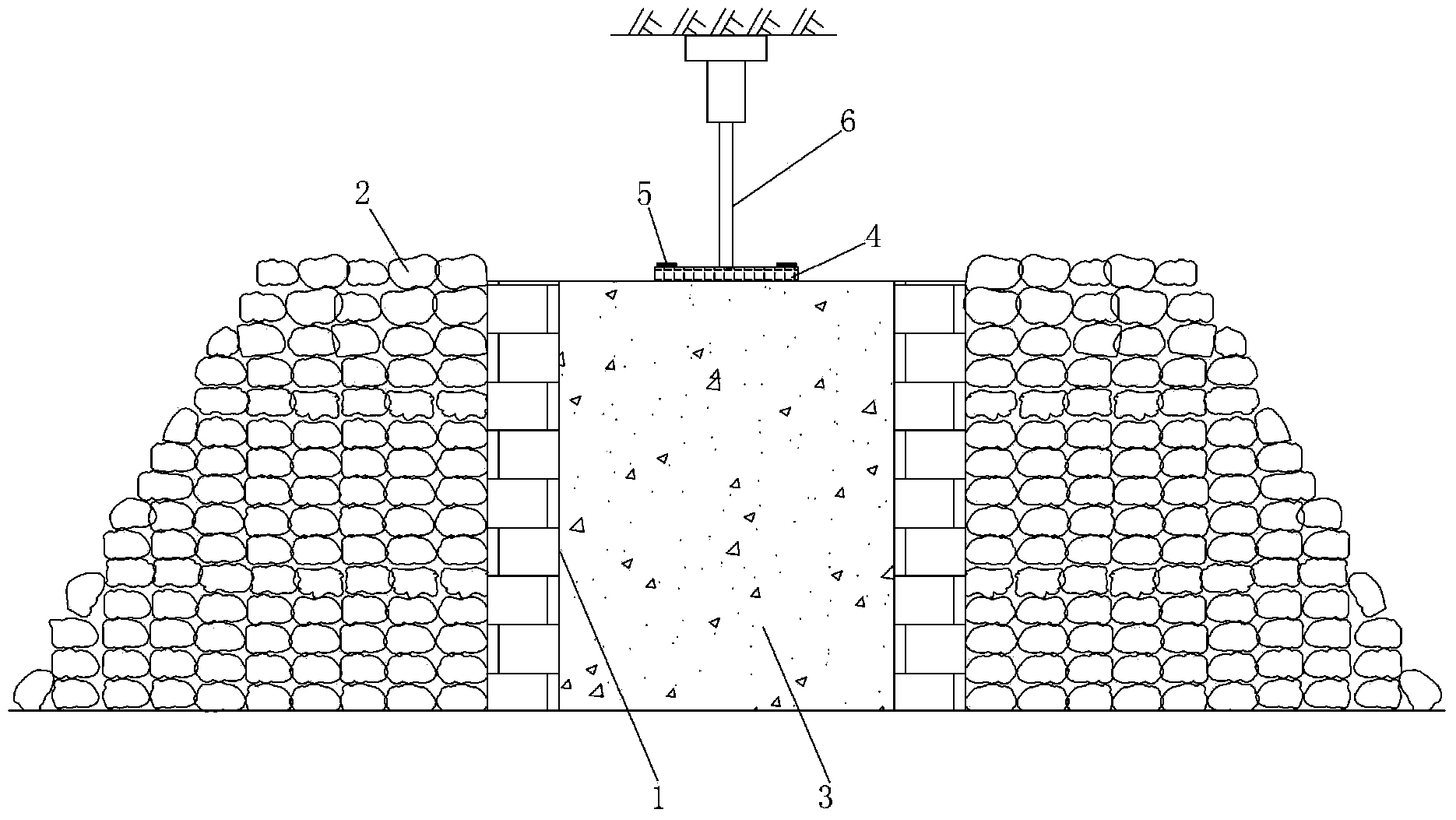

[0043] A1. Model fill side wall construction: A square model fill cavity 1 is formed by laying brick walls on a rigid foundation. The side walls of the model fill cavity 1 do not overlap each other. The width and height of the side walls are 90cm, and close to the outside of the side wall, and build sandbags 2, the total height of the sandbags 2 is ≥90cm;

[0044] A2. Model filling: fill the model 3 with the test geotechnical filler in the model filling cavity 1 according to the predetermined degree of compaction, the filling thickness of each layer is 10-30cm, and the total filling height of the model 3 is 90cm;

[0045] A3. Placement of the loading plate: place a rigid circular loading plate 4 with a diameter of 30 cm at the cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com