Ballastless track construction method with sleepers arranged firstly and rail panel assembled later

A construction method, technology of ballastless track, applied in the direction of track, track laying, track maintenance, etc., can solve the problems affecting the storage of other machinery and equipment, increasing the difficulty of construction, affecting the construction efficiency, etc., to increase the effective utilization rate and reduce the occupation Land issues and the effect of improving transition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

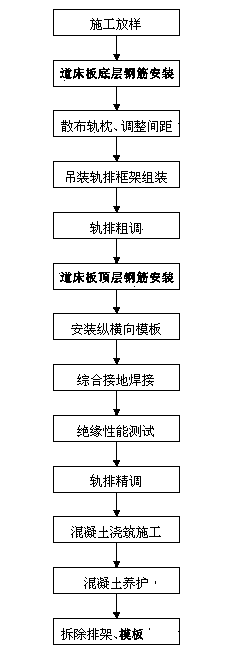

[0039] A construction method for a ballastless track in which sleepers are laid first and then rail rows are assembled, comprising the following steps:

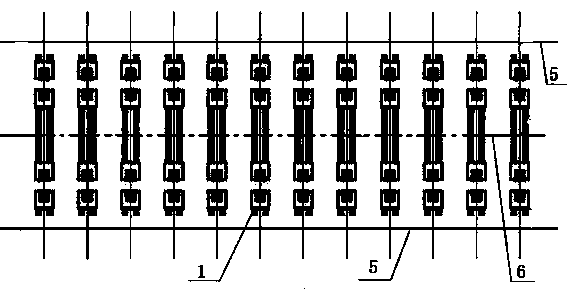

[0040] A. Stake out track centerline 6 and ballast slab sideline 5 on the base plate (base plate in the bridge section) or support layer (support layer in the roadbed section) that has been constructed and passed the inspection.

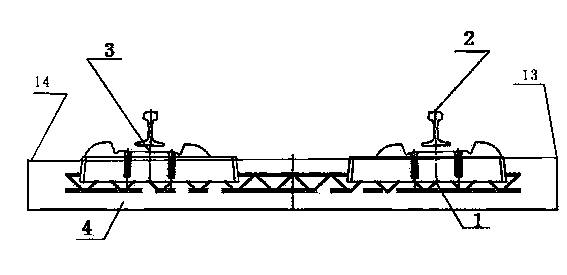

[0041] 1) The inspection of the base plate or supporting layer includes post-construction settlement, beam shrinkage and creep, and CPⅢ control network deployed on site, etc., all of which must meet the design requirements and be accepted by the supervisor. In addition, construction materials such as rail row frame 7, double-block sleeper 1, fasteners 3, and steel bars that have passed the inspection should be advanced to the field. The internal industry m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com