Steel reinforcement cage track skeleton method construction process of steel spring floating plate track

A construction process and floating slab technology, which is applied to tracks, track laying, track maintenance, etc., can solve the problems of difficult construction of floating slab tracks, complicated construction procedures, and high technical requirements, so as to shorten the construction period and make the construction difficult. , the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

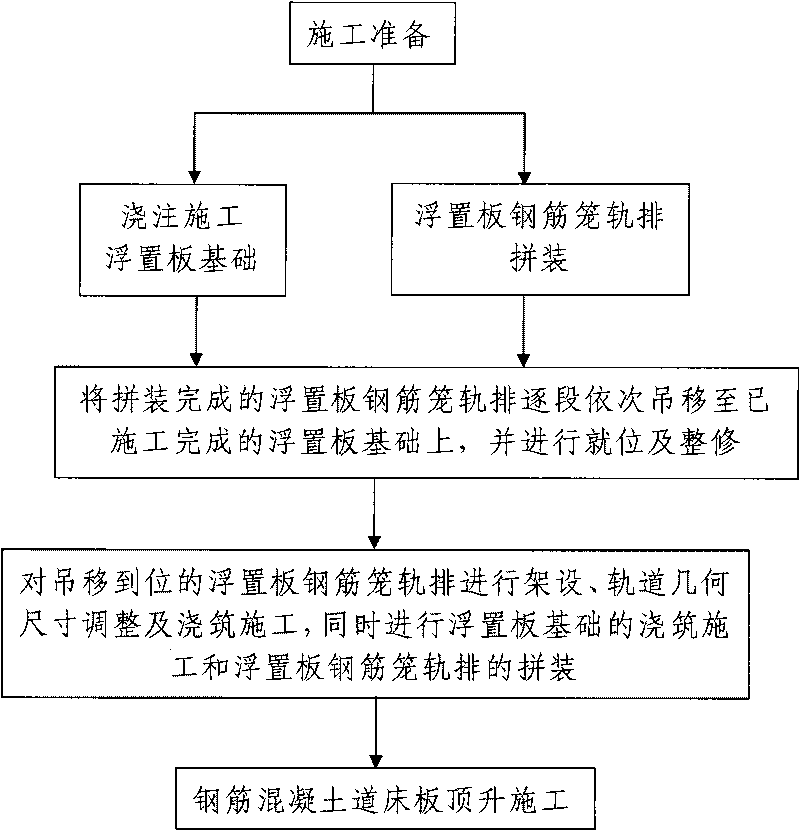

[0074] Such as figure 1 , figure 2 As shown, the steel spring floating slab track reinforcement cage rail row method construction technology of the present invention comprises the following steps:

[0075] Step 1. Construction preparation: Carry out measurement and setting-out and structural dimension deviation inspection for the section where the floating slab track is laid in the construction tunnel.

[0076] In this embodiment, the survey setting out in the construction preparation specifically refers to line adjustment and slope adjustment survey, control base standard retest and base standard encryption survey. Due to comprehensive reasons such as station and tunnel civil construction errors and uneven structural settlement, the center line of the designed line is different from the actual one. In order to ensure that the track meets the requirements of the train operation limit, the plane position and elevation of the line need to be adjusted, and the line will be adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com