Testing method of tensile adhesive strength of flexible polyurethane foam material for polyurethane solidification track bed

A technology of tensile bonding strength and soft polyurethane, which is applied in the field of testing the tensile bonding strength of polyurethane foam materials and ballast, can solve problems such as being unsuitable for evaluating bonding performance, and achieves small data dispersion and reliable principle. , the effect of accurate analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

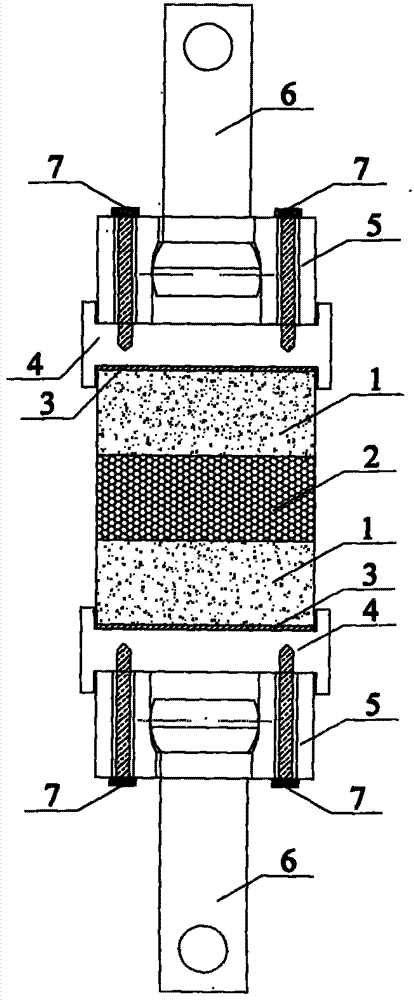

[0010] The method and process for testing the tensile bond strength between the flexible polyurethane foam material 2 and the ballast stone sample 1 will be specifically described below by way of examples.

[0011] 1. Test conditions

[0012] (1) The ballast stone sample is made of super-grade ballast mother rock, and the bonding surface is a flat cutting plane with a certain roughness.

[0013] (2) Two-component epoxy resin superglue is used as the adhesive to ensure that the bonding strength between the positioning base plate and the ballast stone is greater than that between the polyurethane foam material and the ballast stone.

[0014] 2. Test block production

[0015] (1) Use a drilling rig to drill cylindrical ballast stone samples. The size of the test piece is φ50mm×30mm. The allowable deviation of the diameter of the cylinder is ±1mm. The cylindrical test pieces are placed opposite and concentric. It is φ50mm×20mm, and the allowable deviation in the thickness direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com