Built-in type floating track bed and method and device for lifting same

A technology of floating ballast bed and jacking device, which is applied in the field of rail transit, can solve the problems of poor adaptability and large installation space, and achieve the effects of reduced vibration isolation efficiency, high work efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

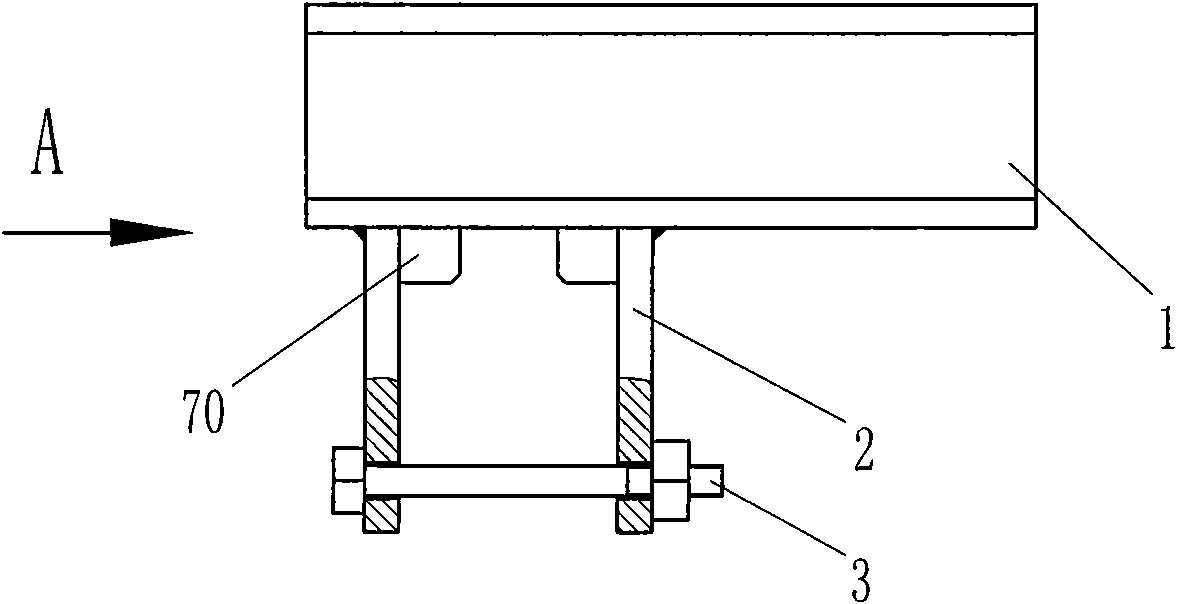

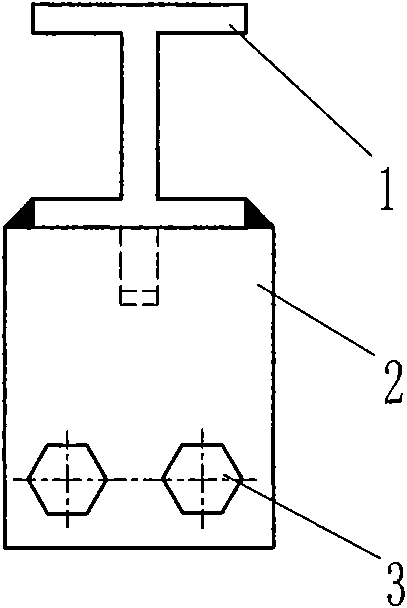

[0070] Such as figure 1 , figure 2 The jacking device shown in the present invention includes a load-bearing beam 1 made of I-shaped steel profiles. A locking fixture that can be reliably connected to the rail is provided on the load-bearing beam 1. The locking fixture includes a pair of ear plates 2 that cooperate with each other. and fixed pin 3. In order to better realize the cooperation between the jacking device of the present invention and the rail, limit blocks 70 are provided on both sides of the bearing beam 1 and the ear plate 2 corresponding to the position of the rail head.

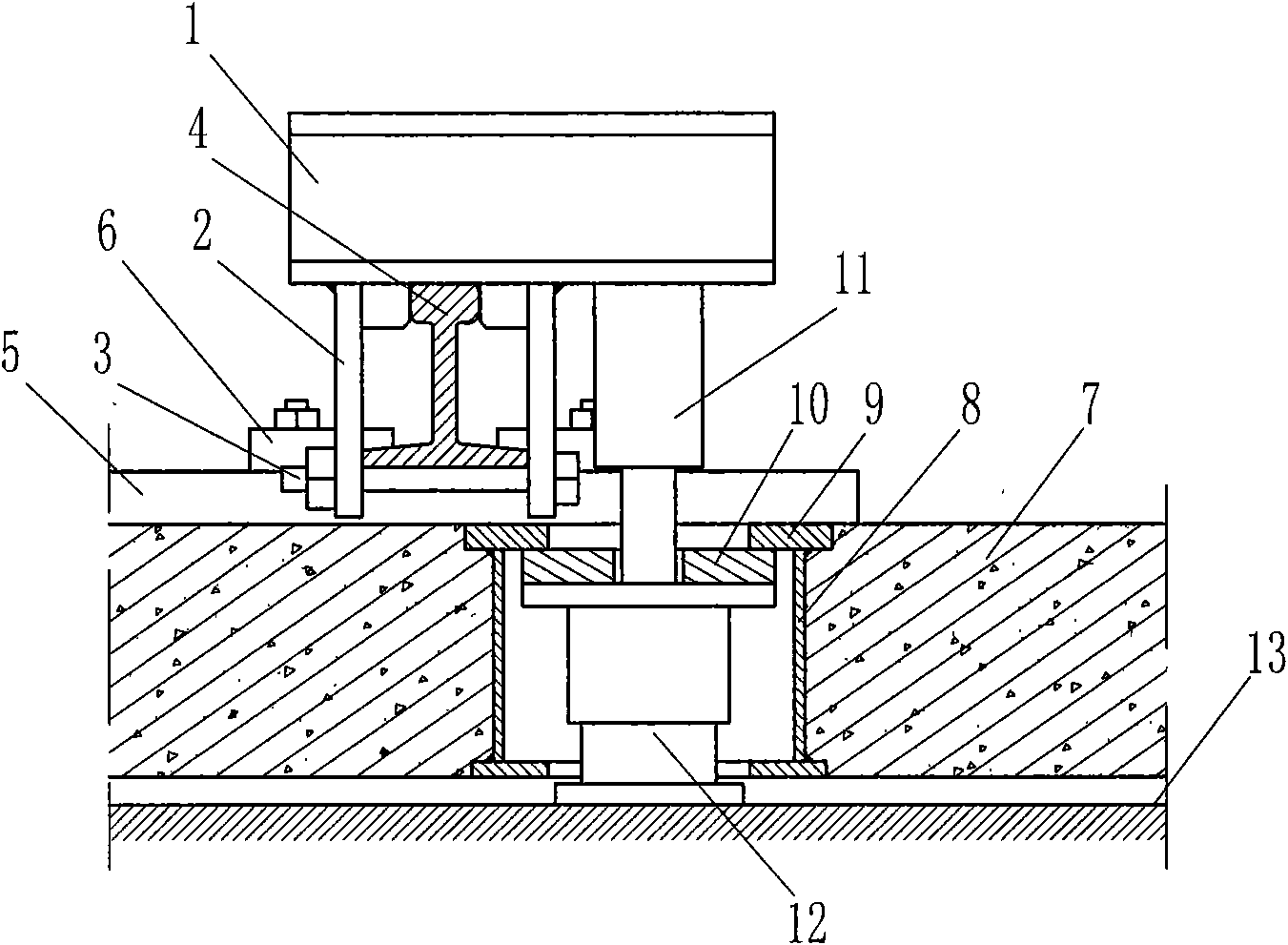

[0071] Such as image 3 As shown, when it is applied to jacking up the floating ballast bed, the rail 4 is generally fixed on the floating plate by the rail fastener 6, firstly, the elastic vibration isolator 12 and the spacer 10 are put into the reserved passage of the floating plate 7 in turn. In the hole, the elastic vibration isolator 12 is located under the support block 9, the gasket...

Embodiment 2

[0075] Such as Figure 4 , Figure 5 The jacking device of the present invention shown differs from Embodiment 1 in that the load beam 1 is formed by butt welding of two channel steels, and the load beam 1 is provided with a locking fixture that can be reliably connected to the rail. The locking fixture includes Two pairs of chain rings 14 and threaded connectors 35 and nuts 15 provided at both ends thereof, the chain rings 14 are connected to the load beam 1 through the threaded connectors 35 and nuts 15 . Limiting blocks 71 are fixedly arranged on both sides of the position corresponding to the rail head on the load beam 1 . In application, only the jacking device of the present invention is fixedly connected with the rail by using the locking fixture, and the rest of the jacking process is the same as that of the first embodiment.

[0076] In addition to the structure shown in this example, based on this connection principle, there are many forms of chain links that can a...

Embodiment 3

[0078] Such as Figure 6 , Figure 7 The jacking device of the present invention shown differs from the first embodiment in that a steel plate 16 is welded at one end of the load-bearing beam 1 made of I-shaped steel to support the jack. A locking fixture that can be reliably connected to the rail is provided on the load beam 1 . The lock fixture includes a lock 17 and a nut 15 , and the lock 17 is connected to the load beam 1 through the nut 15 . In order to improve the stress on the rails, two sets of locking fixtures are provided, and the distance between the two sets of locking fixtures is adapted to the distance between the rails, wherein each set of locking fixtures includes two locking buckles 17 and four nuts 15 . In application, only the jacking device of the present invention and the two rails are fixed together by using the locking fixture, and the rest of the jacking operation steps are the same as those in Embodiment 1.

[0079] Since the steel plate 16 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com