Monolithic track bed construction process for remodeling ballast track subgrade into ballastless track

A technology of integral ballast bed and ballastless track, applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of long blockade time, inconvenient opening to traffic, waste of construction resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the premise of the design of the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to This example.

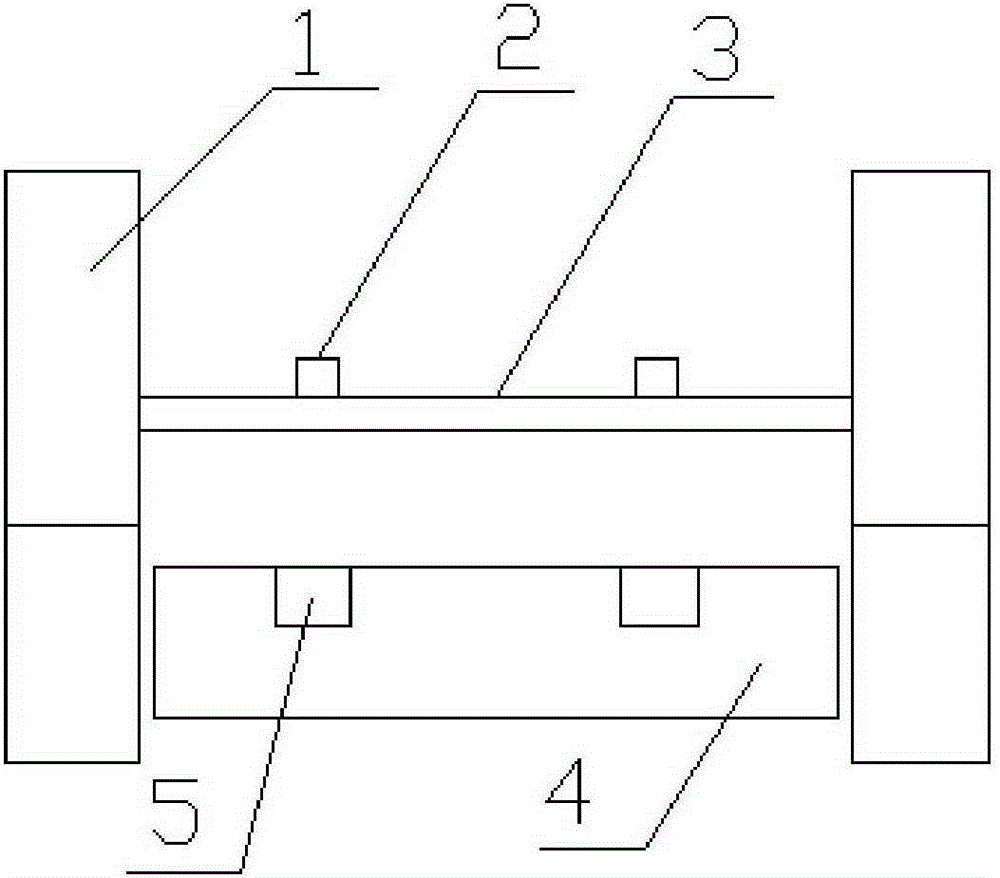

[0028] Such as figure 2 As shown, the names of each part are: convenient beam 1, steel rail 2, convenient beam steel sleeper 3, integral ballast bed 4, and reserved groove 5 for the bearing platform.

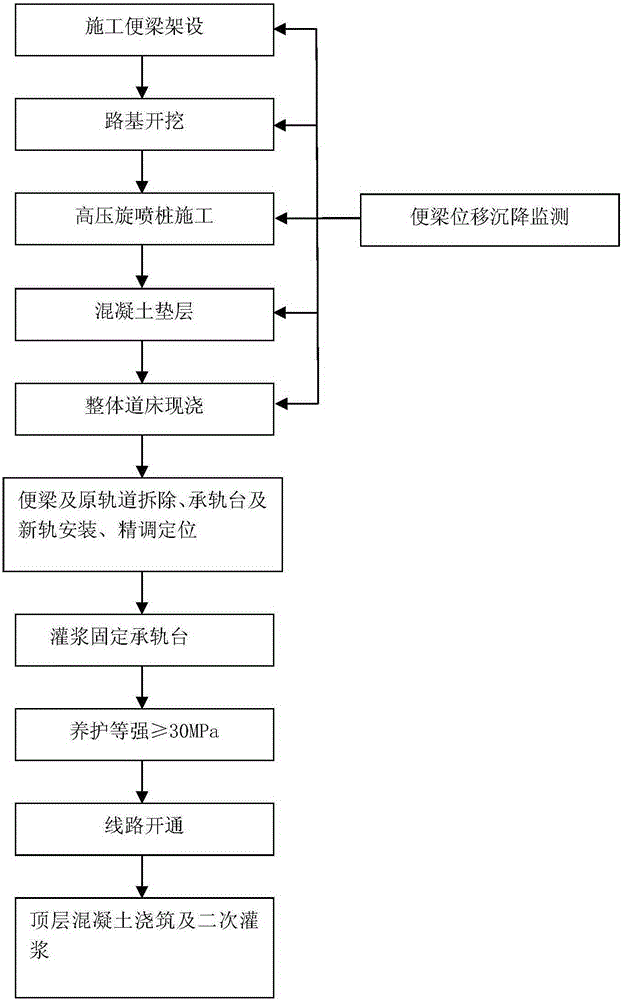

[0029] Such as figure 1 , 2 As shown, a ballasted track subgrade is transformed into a ballastless track integral ballast bed construction process, the specific construction process is as follows:

[0030] a. When erecting construction convenience beams, limit devices are installed on both sides of the convenience beams to prevent left and right slippage, and displacement settlement observation points are arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com