Turnout rail creeping amount monitoring device

A monitoring device and crawling amount technology, which is applied in the field of rail transit safety, can solve the problems of being unable to go on the road, unable to obtain the crawling amount, and unable to obtain the corresponding relationship curve of temperature changes, etc., so as to avoid the effect of train outage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

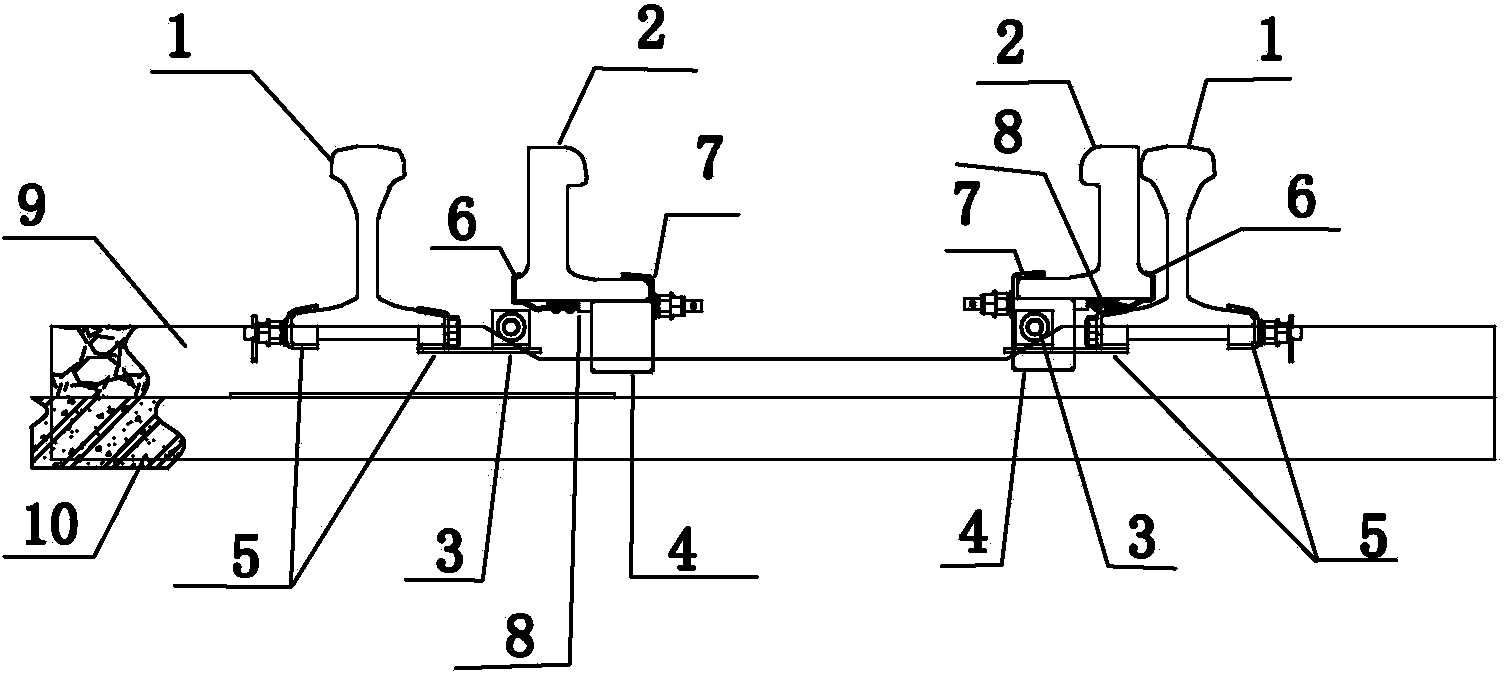

[0021] Refer to attached figure 1 As shown, a turnout rail crawling amount monitoring device of the present invention, the turnout rail includes a pair of turnout basic rails 1 and a pair of turnout point rails 2 located on the opposite inner sides of the turnout basic rails, and the turnout point rails 2 move in two ways: In this state, one of the point rails of the turnout and the basic rail of the turnout on the same side are always kept in close contact position while the other point rail of the turnout is in the repelling position from the basic rail of the same side of the turnout. Two sets of creepage detection components are installed on the same section of the turnout rail. The creepage detection component includes a magnetically conductive metal 4 fixedly installed on the switch point rail and an eddy current sensor 3 fixedly installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com