Cyclic loading tamping teststand for indoor crushed stone ballast track beds

A technology of cyclic loading and test bench, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, measuring devices, instruments, etc., and can solve the problems that cannot meet the needs of bulk ballast bed indoor testing, testing analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

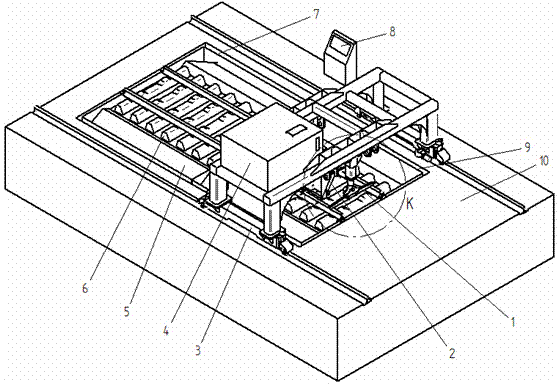

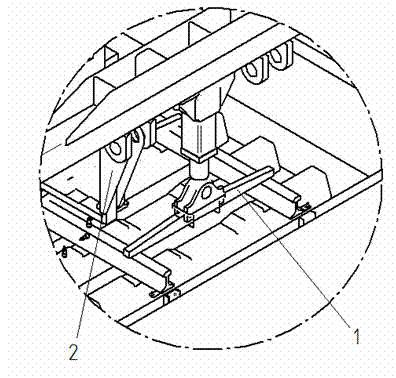

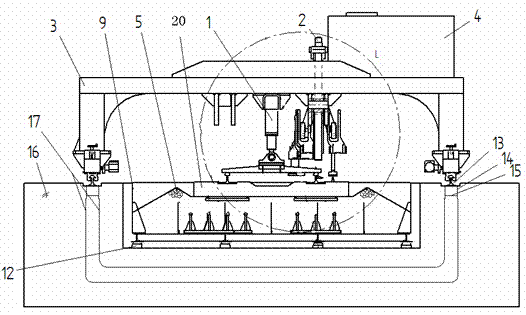

[0060] Embodiment 1: as Figure 1-22 As shown, the indoor ballasted ballast bed cyclic loading tamping test bench includes cyclic loading device 1, tamping device 2, mobile loading trolley 3, loading hydraulic system 4, ballasted bed 5, rail row 6, ballast box Ⅰ7, power supply 8, ballast box Ⅱ9, foundation and foundation pit system 10, ballast bed detection system 11, system shock absorbing device 12, trolley running track 13; two parallel trolley running tracks 13 are installed on the foundation and foundation pit through anchor bolts 14 On the foundation pit system 10, the mobile loading trolley 3 is installed on two parallel trolley travel rails 13; the system damping device 12 is installed on the foundation and the bottom of the foundation pit system 10, and the ballast box I7 and ballast box II9 are placed side by side on the foundation and the foundation pit system 10. In the foundation pit system 10, it is installed above the system shock absorber 12. The system shock a...

Embodiment 2

[0082] Example 2: The indoor ballasted ballast bed cyclic loading tamping test bench includes a cyclic loading device 1, a tamping device 2, a mobile loading trolley 3, a loading hydraulic system 4, a ballasted bed 5, a rail row 6, and ballast Box Ⅰ7, power supply 8, ballast box Ⅱ9, foundation and foundation pit system 10, ballast bed detection system 11, system damping device 12, trolley running track 13; two parallel trolley running tracks 13 are installed on the foundation through anchor bolts 14 And on the foundation pit system 10, the mobile loading trolley 3 is installed on two parallel trolley walking tracks 13; the system shock absorber 12 is installed on the foundation and the bottom of the foundation pit system 10, and the ballast box I7 and the ballast box II9 are placed side by side on the foundation and in the foundation pit system 10, and installed above the system shock absorber 12, the system shock absorber 12 supports the ballast box I7 and the ballast box II9...

Embodiment 3

[0104] Example 3: The indoor ballasted ballast bed cyclic loading tamping test bench includes a cyclic loading device 1, a tamping device 2, a mobile loading trolley 3, a loading hydraulic system 4, a ballasted bed 5, a rail row 6, and ballast Box I7, power supply 8, ballast box II9, foundation and foundation pit system 10, ballast bed detection system 11, system damping device 12, trolley running track 13; two parallel trolley running tracks 13 are installed on the foundation through anchor bolts 14 And on the foundation pit system 10, the mobile loading trolley 3 is installed on two parallel trolley walking tracks 13; the system shock absorber 12 is installed on the foundation and the bottom of the foundation pit system 10, and the ballast box I7 and the ballast box II9 are placed side by side on the foundation and in the foundation pit system 10, and installed above the system shock absorber 12, the system shock absorber 12 supports and isolates the ballast box I7 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com