Rail sleeper and ballast-free track structure

a track structure and rail sleeper technology, applied in the direction of track superstructure, railway track construction, ways, etc., can solve the problems of minor and fundamental improvement in the design and construction of conventional railway tracks, serious and persistent problems that have never been completely resolved, and the progressive degradation of track structures under repeated loading remains problematic, so as to facilitate rapid installation and replacement of railway tracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Without limiting the scope thereof, two embodiments of the invention will now be described by way of example only and with reference to the accompanying drawing wherein—

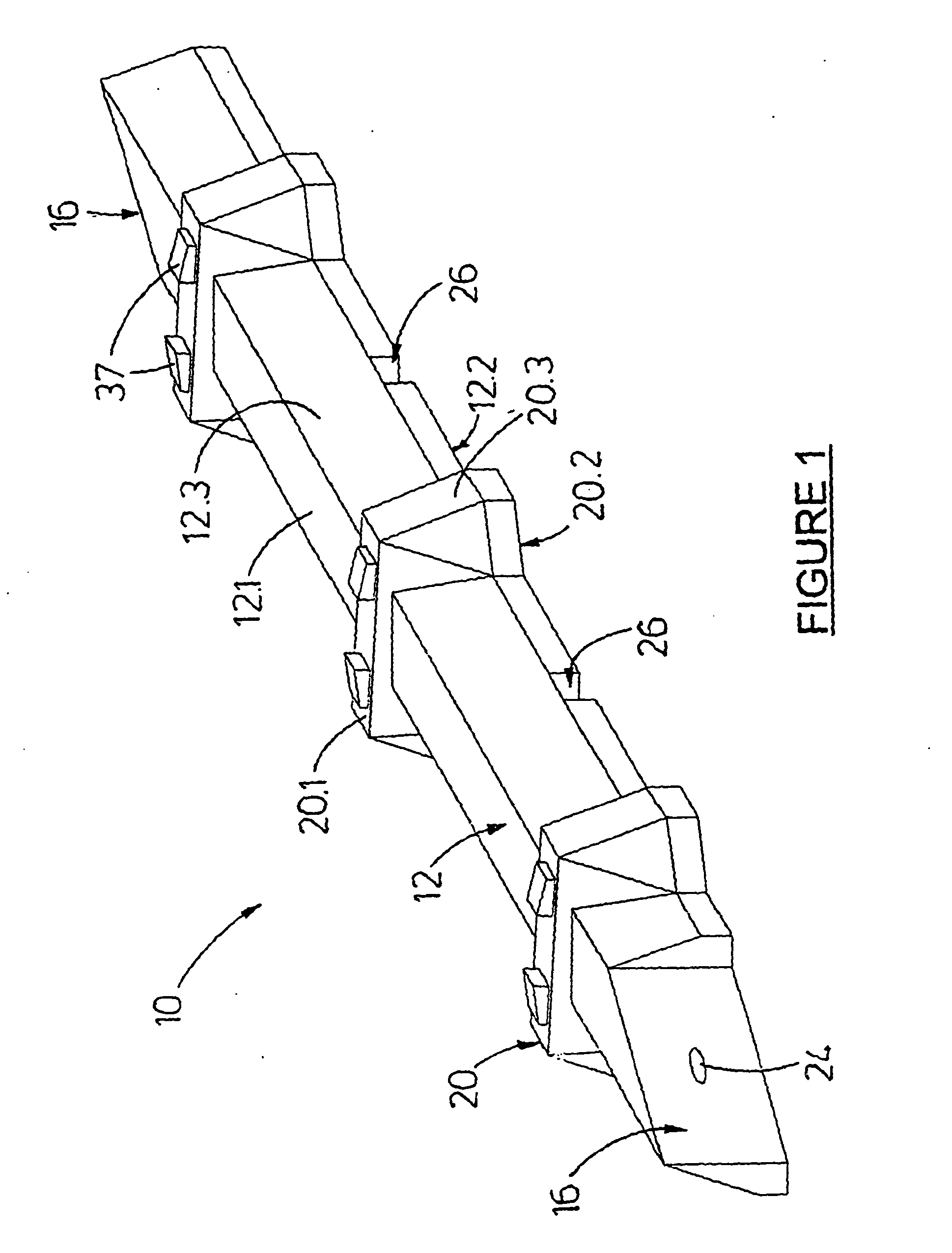

[0044]FIG. 1 is an isometric view of a rail sleeper according to one embodiment of the invention, wherein the rail sleeper is designed for light axle load applications such as underground mining;

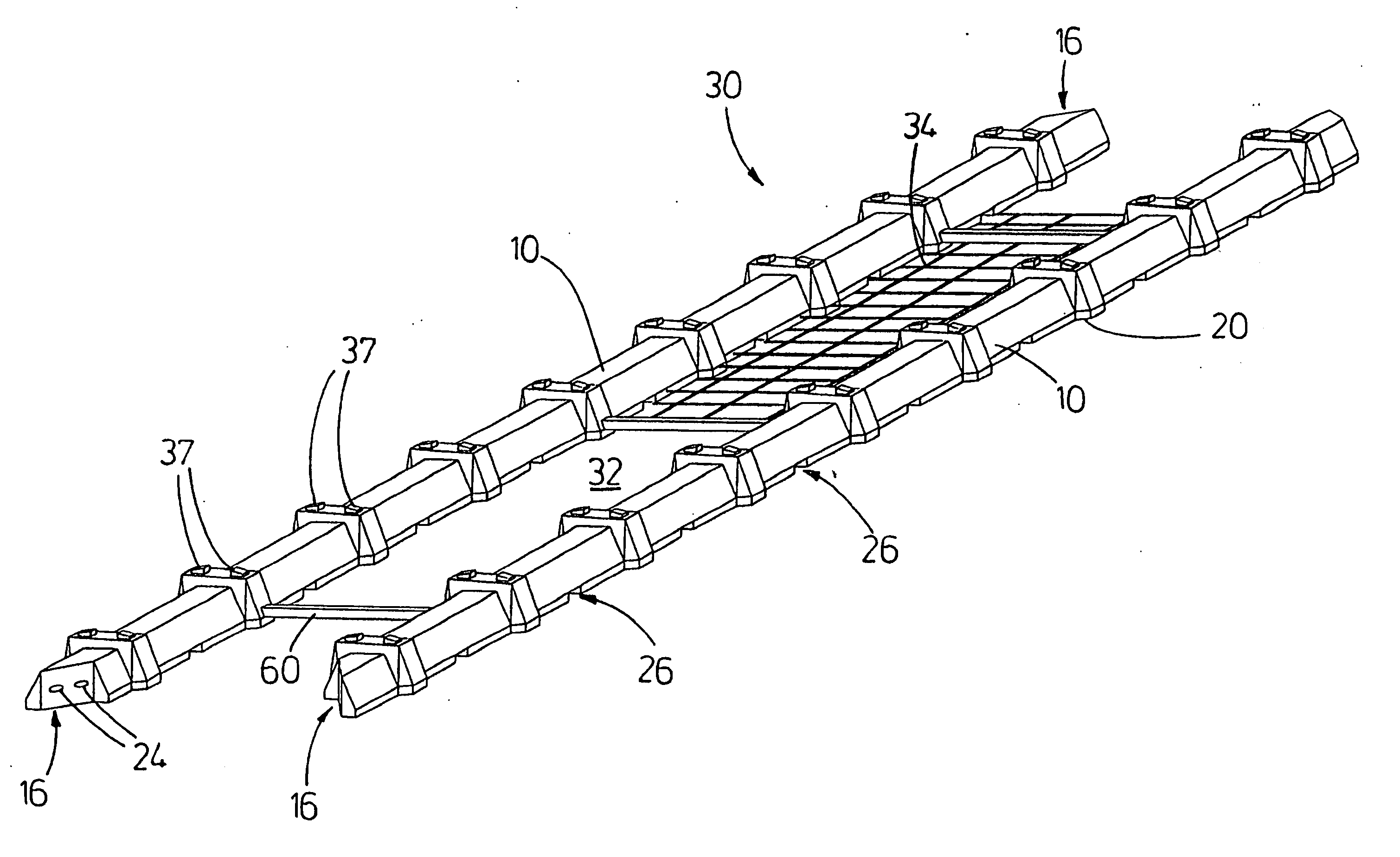

[0045]FIG. 2 is an isometric view of a rail sleeper according to another embodiment of the invention, wherein the rail sleeper is designed for heavier axle loads such as main line applications;

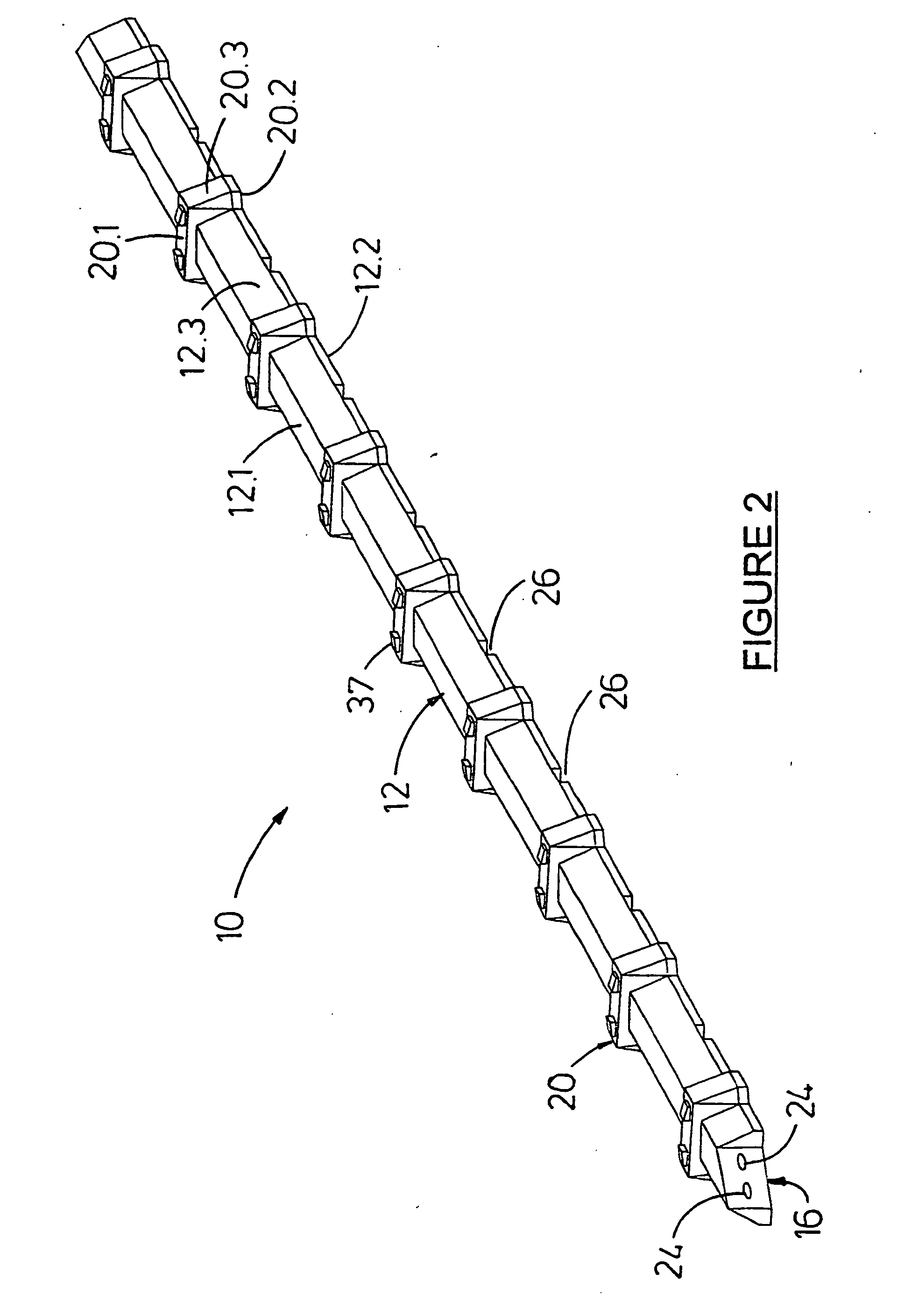

[0046]FIG. 3 is an isometric view of a track structure according to one embodiment of the invention;

[0047]FIG. 4 is an isometric view of a track structure according to another embodiment of the invention, including a wire mesh extending between the sleepers;

[0048]FIG. 5 is a transverse cross-sectional view of the track structure of FIG. 4;

[0049]FIG. 6 is a transverse cross-sectional view of a track structure according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com