Modularized steel structure track bed with adjustable gauge

A modular and steel structure technology, applied in the direction of tracks, roads, ballast layers, etc., can solve the problems of not realizing adjustable gauge and modularization, and achieve the effect of convenient assembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

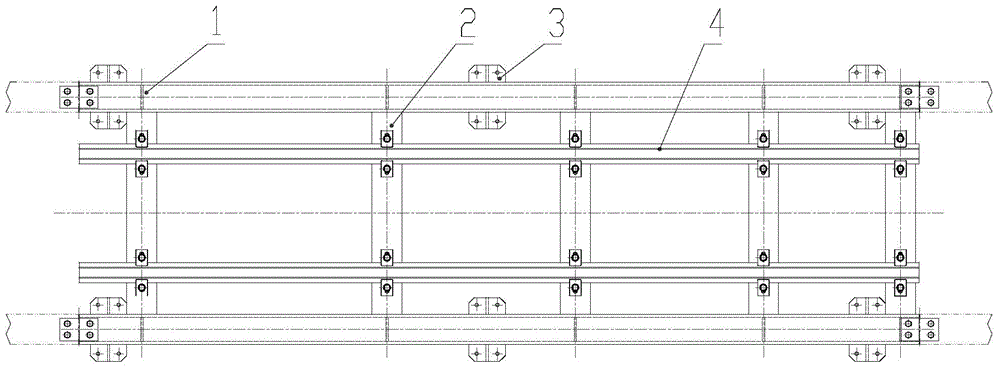

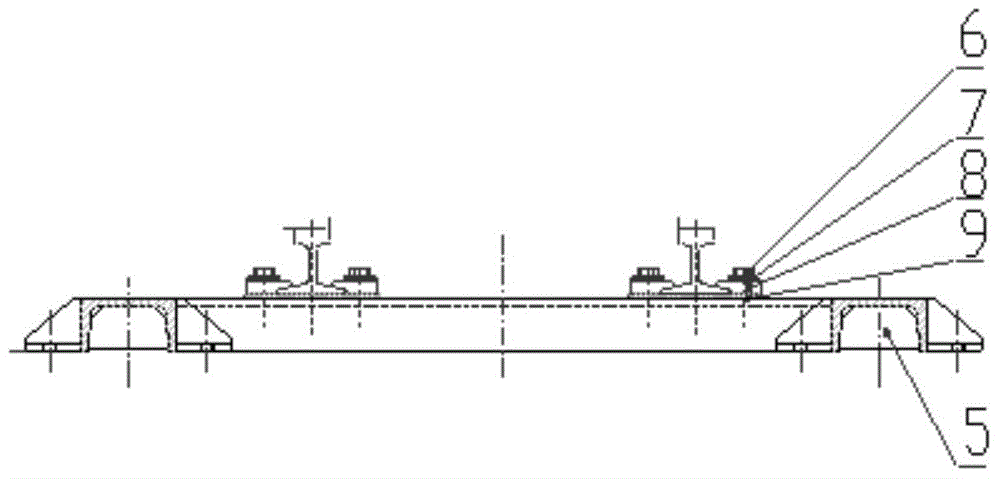

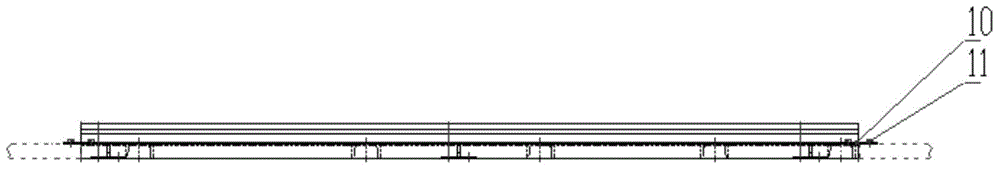

[0023] An adjustable gauge modular steel structure track bed, its structure is as follows Figure 1-3 As shown, it is a modular structure spliced sequentially, and each module is made into different lengths between 2m and 5m. Adjacent modules are connected through connecting plates 10 and fixing bolts 11 for connecting plates. The module includes longitudinal channel steel frames 1 and transverse channel steel frames 2 that are vertically connected to each other. The longitudinal channel steel frames 1 are arranged on both sides of the track 4 and the distance is adjusted according to the gauge of the track 4. On the basis of installation, the gauge of the track 4 is 143.5-1435mm, that is, the gauge varies from the standard gauge of 1435mm to the gauge of 1:10, and the gauge of the corresponding longitudinal channel steel frame 1 is 500-2500mm. A reinforcement partition 5 is provided at the bottom of the longitudinal channel steel frame 1 . The connecting plate 10 is a rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com